Sheet metal working is a process whereby flat metal sheets (usually between 0.15 mm and 10 mm thick) are made into components and structures of various shapes. The raw material for this process is flat sheet metal. Sheet metal fabrication is used to manufacture objects such as housings, enclosures, brackets, stamped parts, crimps, etc. It is also used for decorative purposes and various patterns can be created on the sheet metal.

How is sheet metal working performed?

The transition from raw material to final product usually requires one or more of the following three processes: material removal (cutting), deformation, and assembly. If all of these processes need to be performed, they are usually done in chronological order.

Material Removal

This involves cutting the raw material to obtain the desired shape. To ensure maximum accuracy, speed and efficiency, CNC waterjet, plasma and laser cutting techniques are often used. In some cases, Electrical Discharge Machining (EDM) may also be an option.

Laser Cutting

Laser cutting utilizes a high-density laser beam directed at a workpiece to precisely cut material by melting, evaporating, or burning. Laser cutters are widely used for cutting, punching and engraving. Three common types of lasers include CO2 (carbon dioxide), Nd (neodymium), and Nd:YAG (neodymium-doped yttrium aluminum garnet), each of which has different advantages and applications in cutting technology.

CO2 lasers offer high energy efficiency and high power output ratios and are primarily used for cutting thin materials, engraving and punching. nd lasers have high energy but low repetition efficiencies and are suitable for engraving, punching and welding. nd:YAG lasers have a very high power output, allowing for the cutting of thicker materials, but have higher operating costs than CO2 lasers.Sheet metal working is a process whereby flat metal sheets (usually between 0.15 mm and 10 mm thick) are made into components and structures of various shapes. The raw material for this process is flat sheet metal. Sheet metal fabrication is used to manufacture objects such as housings, enclosures, brackets, stamped parts, crimps, etc. It is also used for decorative purposes and various patterns can be created on the sheet metal. How is sheet metal working performed? The transition from raw material to final product usually requires one or more of the following three processes: material removal (cutting), deformation, and assembly. If all of these processes need to be performed, they are usually done in chronological order. Material Removal This involves cutting the raw material to obtain the desired shape. To ensure maximum accuracy, speed and efficiency, CNC waterjet, plasma and laser cutting techniques are often used. In some cases, Electrical Discharge Machining (EDM) may also be an option. Laser Cutting Laser cutting utilizes a high-density laser beam directed at a workpiece to precisely cut material by melting, evaporating, or burning. Laser cutters are widely used for cutting, punching and engraving. Three common types of lasers include CO2 (carbon dioxide), Nd (neodymium), and Nd:YAG (neodymium-doped yttrium aluminum garnet), each of which has different advantages and applications in cutting technology. CO2 lasers offer high energy efficiency and high power output ratios and are primarily used for cutting thin materials, engraving and punching. nd lasers have high energy but low repetition efficiencies and are suitable for engraving, punching and welding. nd:YAG lasers have a very high power output, allowing for the cutting of thicker materials, but have higher operating costs than CO2 lasers.

Laser cutting machines are used for aluminum, steel, copper, stainless steel and other metals. They are best suited for cutting thin workpieces (maximum thickness of 15 mm for aluminum and 6 mm for steel), engraving and punching.

Waterjet Cutting

In waterjet cutting, a nozzle is used to focus a high-pressure stream of water on the workpiece for cutting. For relatively soft materials such as rubber and wood, only water is used. Whereas for hard materials such as metal, a mixture of water and abrasive particles is used for cutting.Laser Cutting Process Laser cutting machines are used for aluminum, steel, copper, stainless steel and other metals. They are best suited for cutting thin workpieces (maximum thickness of 15 mm for aluminum and 6 mm for steel), engraving and punching. Waterjet Cutting In waterjet cutting, a nozzle is used to focus a high-pressure stream of water on the workpiece for cutting. For relatively soft materials such as rubber and wood, only water is used. Whereas for hard materials such as metal, a mixture of water and abrasive particles is used for cutting.

Waterjet cutting can cut materials of various thicknesses. The maximum thickness that can be cut depends on the type of material. Of all the CNC cutting methods, waterjet cutting has the highest accuracy, with tolerances ranging from 0.05 millimeters to 0.1 millimeters. One reason for its high accuracy is that, unlike plasma and laser cutting, waterjet cutting generates no heat, so there is no heat affected zone in the workpiece.

Waterjet cutting is very flexible and can be used to cut hard materials such as aluminum, steel, copper, stainless steel and other metal alloys, as well as softer materials such as polymers, elastomers, wood and foam.

Plasma Cutting

Plasma cutting converts a gas into plasma by applying heat and energy to it. The hot plasma is then accelerated from the cutting nozzle using inert gas or air and applied to the workpiece. The plasma forms an electric arc with the workpiece, causing it to melt and cut. As an electrical process, plasma cutting can only handle electrically conductive materials.Waterjet Cutting Process Waterjet cutting can cut materials of various thicknesses. The maximum thickness that can be cut depends on the type of material. Of all the CNC cutting methods, waterjet cutting has the highest accuracy, with tolerances ranging from 0.05 millimeters to 0.1 millimeters. One reason for its high accuracy is that, unlike plasma and laser cutting, waterjet cutting generates no heat, so there is no heat affected zone in the workpiece. Waterjet cutting is very flexible and can be used to cut hard materials such as aluminum, steel, copper, stainless steel and other metal alloys, as well as softer materials such as polymers, elastomers, wood and foam. Plasma Cutting Plasma cutting converts a gas into plasma by applying heat and energy to it. The hot plasma is then accelerated from the cutting nozzle using inert gas or air and applied to the workpiece. The plasma forms an electric arc with the workpiece, causing it to melt and cut. As an electrical process, plasma cutting can only handle electrically conductive materials.

Plasma Cutting Machines can cut very thick materials such as aluminum up to 300 mm and steel up to 200 mm with a tolerance of 0.2 mm. Stainless steel, copper and other metal alloys can also be handled using a plasma cutter. Depending on the complexity of the part required, there is the option of using either a 2-axis or 3-axis cutter.

Although plasma cutters are not as versatile and precise as waterjet and laser cutters, they are the best choice for thick conductive metal parts as they are faster and more cost effective in cutting such materials.

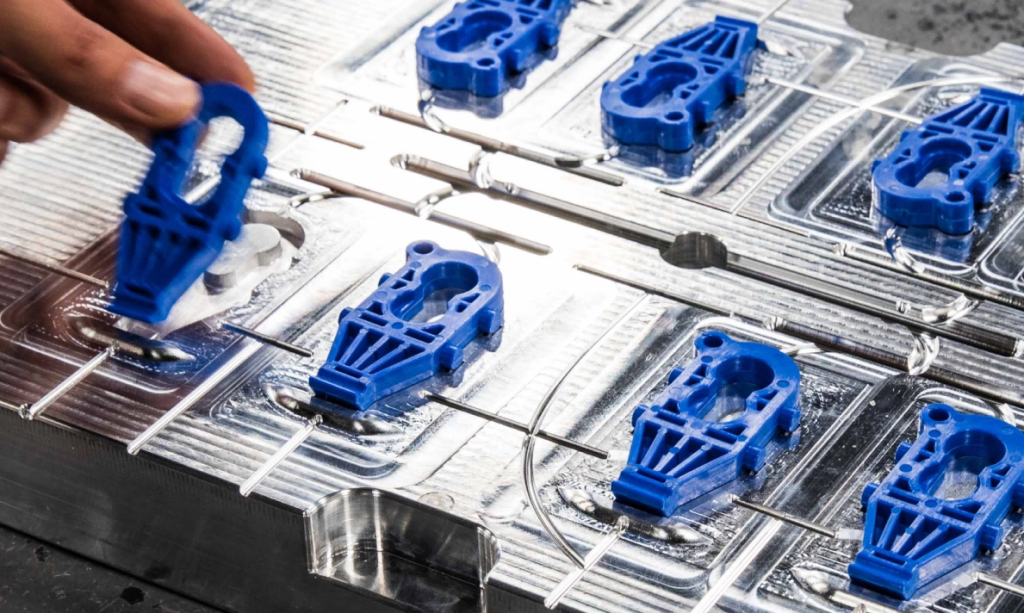

Deformation

This process involves the controlled application of force to bend or form sheet metal into a desired shape. The deformation process includes bending, forming, stamping and stretching using dies, hydraulics and electromagnetic brakes.Plasma Cutting Process Plasma Cutting Machines can cut very thick materials such as aluminum up to 300 mm and steel up to 200 mm with a tolerance of 0.2 mm. Stainless steel, copper and other metal alloys can also be handled using a plasma cutter. Depending on the complexity of the part required, there is the option of using either a 2-axis or 3-axis cutter. Although plasma cutters are not as versatile and precise as waterjet and laser cutters, they are the best choice for thick conductive metal parts as they are faster and more cost effective in cutting such materials. Deformation This process involves the controlled application of force to bend or form sheet metal into a desired shape. The deformation process includes bending, forming, stamping and stretching using dies, hydraulics and electromagnetic brakes.

Assembly

This is the process of combining various machined workpieces to form a final product. The assembly process includes welding, brazing, riveting, and sometimes the use of adhesives.

Materials

The metals best suited for use in this process include aluminum and its alloys, steel, copper and its alloys, and stainless steel. The following table lists the most popular grades of metals used for sheet metal working.

| Aluminum | Copper | Stainless | Steel |

| DIN 3.3523 | EN AW5052 | DIN 2.0065 | EN CW004A | 1.4319 | mild steel |

| DIN 3.3211 | EN AW6061 | DIN 2.0265 | EN CW505L | 1.4301 | low-carbon steel |

| DIN 3.3535 | EN AW5754 | DIN EN 13601 | EN CW009A | 1.4404 |

Post-processing operations

In sheet metal processing, common post-processing operations include shot blasting, anodizing, powder coating, and painting. For deformed or welded materials, heat treatment is performed to eliminate residual stress.

Advantages of sheet metal processing

The advantages of sheet metal processing are as follows.

- Durability: This process can produce highly durable products, whether for prototyping or final use.

- Scalability and cost-effectiveness: Whether you need a single one-off part or large-scale production, sheet metal processing offers a fast and cost-effective solution.

- Material selection: This processing method can handle a wide range of metals, allowing you to choose from hundreds of metals with different properties.

- Fast turnaround: CNC technology makes sheet metal processing both fast and efficient.

Industries that use sheet metal processing

Any industry that uses metal components may involve sheet metal processing. Here are some industries that utilize this process:

- Machinery manufacturing

- Engineering and design

- Metal processing

- Electronics

- Furniture and urban infrastructure

- Robotics

- Medical and healthcare

- Automotive

- Musical instruments

- Civil engineering

Conclusion

At Debaolong Seiko, we offer high-precision, fast, and high-quality sheet metal processing services, capable of producing various sheet metal components made from aluminum, steel, copper alloys, and other materials. By utilizing automated cutting technologies such as CNC laser cutting, plasma cutting, and waterjet cutting, as well as forming and assembly techniques, we ensure the high precision and quality of our finished products.