Abstract

This article dissects four core CNC machining processes—milling, turning, drilling, and grinding—covering technical principles, equipment selection, and industry applications. With visual diagrams and SEO-optimized keywords, it offers the manufacturing professionals a practical guide to process selection, precision control, and cost optimization for enhanced production efficiency.

1. Milling: The Core of Complex Surface Machining

1.1 Technical Principles

Milling uses rotating cutters to machine planes, slots, or 3D surfaces, supporting multi-axis (3/5-axis) operations. Typical equipment: vertical/horizontal machining centers.Key Parameters:

- Spindle speed: 800–24,000rpm

- Feed rate: 50–5,000mm/min

- Precision: ±0.005–0.05mm

1.2 Applications

- Aerospace: 5-axis milling of turbine blades (surface roughness Ra≤0.8μm)

- Mold Manufacturing: High-precision machining of injection mold cavities (tolerance ±0.01mm)

- Medical Devices: Machining complex surfaces of joint prostheses

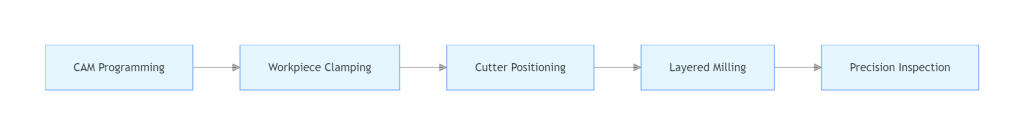

Visual: Milling Workflow Diagram

graph LR

A[CAM Programming] --> B[Workpiece Clamping] --> C[Cutter Positioning] --> D[Layered Milling] --> E[Precision Inspection]2. Turning: Precision Machining for Rotational Parts

2.1 Technical Principles

The workpiece rotates while the tool feeds linearly to machine cylindrical, conical, or threaded surfaces. Typical equipment: CNC lathes, turn-mill composite machines.Advantages:

- Multi-process machining in one clamping (turning + milling + drilling)

- Threading precision up to ISO 4H class

2.2 Applications

- Automotive: Precision turning of engine crankshafts (roundness ≤0.003mm)

- Electronics: High-speed turning of connector terminals (40% efficiency gain)

- Precision Instruments: Nano-level turning of micro shafts

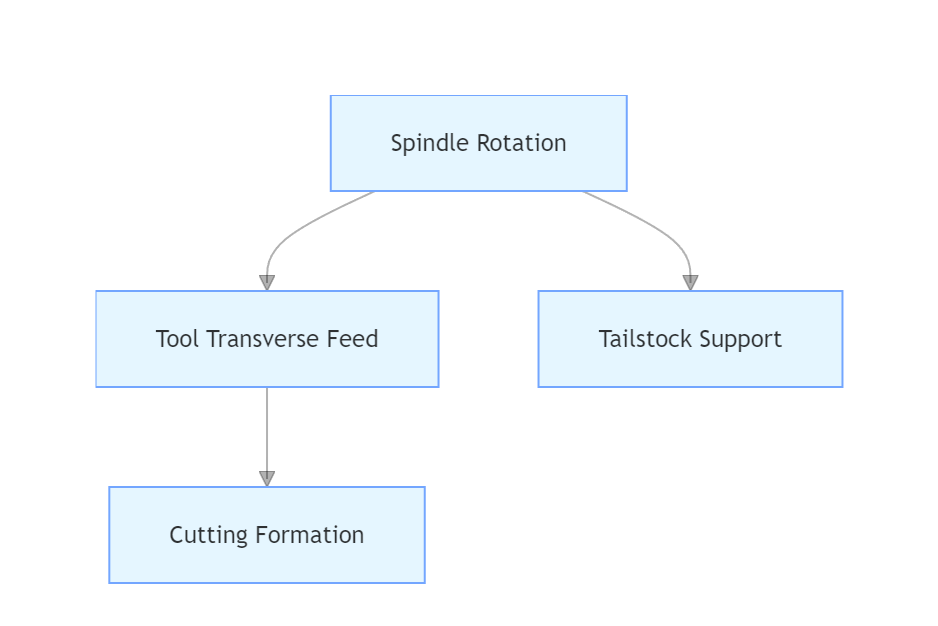

Visual: Turning Process Schematic

graph TD

A[Spindle Rotation] --> B[Tool Transverse Feed]

A --> C[Tailstock Support]

B --> D[Cutting Formation] 3. Drilling & Boring: Full-Spectrum Hole Machining

3.1 Drilling: Rapid Production of Standard Holes

- Equipment: CNC drilling machines, machining centers

- Key Points:

- Drill speed: 1,000–15,000rpm (aluminum)

- Internal cooling drills reduce tool wear

3.2 Boring: High-Precision Hole Finishing

- Precision: Hole tolerance up to H7, surface roughness Ra≤1.6μm

- Applications: Deep-hole boring of hydraulic valve bodies (depth-diameter ratio >20:1)

Comparison Table: Drilling vs. Boring

| Process | Precision Range | Typical Hole Size | Tool Life |

| Drilling | ±0.1–0.3mm | φ1–φ50mm | 500–1,000 parts |

| Boring | ±0.005–0.02mm | φ20–φ300mm | 2,000–5,000 parts |

4. Grinding: Ultimate Surface Precision Assurance

4.1 Technical Features

Grinding uses abrasive tools (wheels/stones) for micro-cutting, achieving micron-level precision (±0.001mm) and surface roughness Ra≤0.2μm.

4.2 Applications

- Aero-Engines: Mirror grinding of turbine journals (roundness ≤0.0005mm)

- Precision Molds: Lapping of ejector pin holes (Ra≤0.1μm)

Visual: Precision Comparison Chart

barChart

title Precision Comparison of Machining Processes

xAxis Process Types

yAxis Precision (μm)

series Precision Values

Milling: 5-50

Turning: 2-20

Grinding: 0.1-5Conclusion

Choosing the right CNC process directly impacts efficiency and cost. Milling excels at complex shapes, turning at rotational parts, drilling/boring at hole features, and grinding at ultimate precision. Strategic combinations (e.g., 5-axis milling + precision grinding) can significantly enhance yield rates and competitiveness in high-end manufacturing.