[Abstract]

This article, professionally presented by Debaolong Seiko, deeply analyzes the technical definition of CNC machining, traces its development history, compares with traditional processing methods, and demonstrates its outstanding advantages in precision, efficiency, and flexibility. Through application cases in medical devices, new energy vehicles, aerospace, and other fields, it reveals how CNC machining reshapes the modern manufacturing landscape, providing a comprehensive technical understanding and practical reference for industry participants.

1. Technical Definition and Core Architecture of CNC Machining

CNC (Computer Numerical Control) machining is an advanced manufacturing technology that uses computer programs (such as G – codes, M – codes) to precisely control the movement trajectory and process parameters of machine tools, achieving automated processing of metal or non – metal materials. Its core lies in transforming digital instructions into precise actions of machine tools, thus achieving precision and complexity that are difficult to reach in traditional processing.

1.1 Analysis of Core Components

- Control System: Such as Siemens and Fanuc numerical control systems, with high – speed instruction processing capability (up to 1000 blocks/second) to ensure accurate program execution.

- Servo System: High – precision servo motors achieve a positioning accuracy of ±0.001mm, providing real – time feedback and adjusting the movement of machine tools.

- Execution Mechanism: High – speed spindle (up to 24,000rpm) and intelligent tool magazine (with a capacity of 30 – 120 tools), supporting diverse processing needs.

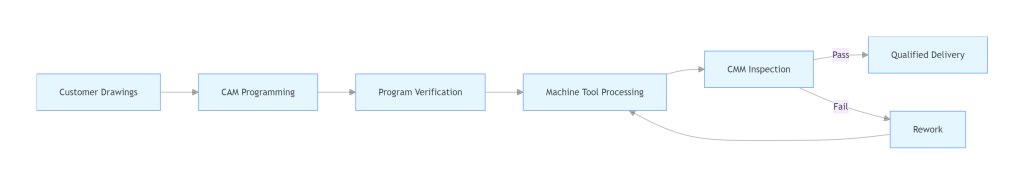

1.2 Standardized Workflow

- Receiving and Analyzing Customer Drawings: The professional technical team of Debaolong Seiko first deeply studies the drawings provided by customers, clarifying key requirements such as dimensional specifications, geometric tolerances, and material properties to ensure the accuracy of subsequent processing directions.

- CAM Programming: Using professional computer – aided manufacturing (CAM) software, convert the drawing design into a numerical control program recognizable by the machine tool. During programming, engineers optimize the tool path, taking into account both processing efficiency and surface quality. For example, a layered milling strategy is used for complex surfaces to reduce tool wear and improve accuracy.

- Program Verification: Simulate the processing of the generated numerical control program through simulation software, check for collision risks between the tool and the workpiece, fixture, etc., and verify whether the processing path meets the drawing requirements to avoid program errors during formal processing.

- Workpiece and Tool Clamping: Accurately install the workpiece on the machine tool to ensure firm clamping and accurate positioning; select appropriate tools according to the processing technology, load them into the tool magazine in turn, and perform tool length and radius compensation settings to prepare for automated processing.

- Machine Tool Automated Processing: Start the CNC machine tool, and the control system drives the spindle rotation and tool movement according to the preset program, performing multi – process processing such as milling, turning, and drilling on the workpiece. During processing, the machine tool feeds back parameters such as position and speed in real – time to ensure that the actions are completely consistent with the program.

- Real – time Monitoring and Adjustment: Operators observe the processing status in real – time through the machine tool control panel or monitoring system, including parameters such as cutting force, temperature, and vibration. If an abnormality is found (such as dimensional deviation caused by tool wear), stop the processing in time and adjust the parameters or replace the tool.

- CMM Inspection: After processing is completed, use a Coordinate Measuring Machine (CMM) to comprehensively inspect the workpiece, comparing the actual dimensions and geometric tolerances with the drawing requirements. The inspection laboratory of Debaolong has passed ISO17025 certification to ensure the authority and reliability of inspection results.

- Qualified Delivery: Clean and rust – proof the inspected qualified workpieces, pack them according to customer requirements, and deliver them. If the inspection is not up to standard, initiate a quality traceability process, analyze the reasons, and re – process until the standards are met.

2. The Evolution Path of CNC Machining Technology

| Stage | Time | Core Breakthrough | Impact on Processing |

| NC (Numerical Control) | 1950s | Machine tool movement controlled by punch tape | Get rid of manual operation, realize simple straight – line/circular arc processing |

| CNC (Computer Numerical Control) | 1970s | Microcomputer replaces hardware circuit | Support complex program storage and real – time control |

| Intelligent Numerical Control | 2010s – present | Internet of Things (IoT) + AI process optimization | Processing efficiency increased by 30%, predictive maintenance |

Debaolong Seiko actively innovates in the stage of intelligent numerical control, introducing an AI cutting parameter optimization system, automatically generating the optimal feed rate for titanium alloy parts, and increasing processing efficiency by 25%, demonstrating technological leadership.

3. Remarkable Advantages of CNC Machining Compared with Traditional Machining

3.1 Precision Dimension: From Millimeter to Micron

| Processing Type | Dimensional Tolerance | Surface Roughness Ra | Typical Applications |

| Traditional Manual Machining | ±0.1 – 0.5mm | 12.5 – 3.2μm | Ordinary brackets |

| Ordinary Machine Tool Machining | ±0.05 – 0.1mm | 6.3 – 1.6μm | Automobile flanges |

| Debaolong CNC Machining | ±0.005 – 0.05mm | 1.6 – 0.2μm | Medical joints, aerospace blades |

3.2 Machining Capability for Complex Structures

Traditional machining faces problems such as large clamping errors and long time – consuming in deep – cavity (depth ≥ 10 times diameter) and free – form surfaces (such as impellers). Debaolong CNC achieves one – time forming of aerospace blades through five – axis machining (surface accuracy ±0.01mm), and processes aluminum alloy thin – walled parts (wall thickness 0.5mm, deformation ≤0.02mm) through high – speed milling technology, breaking through traditional limitations.

4. Industry Application Practices of Debaolong CNC Machining

4.1 Medical Device Field

For the demand of orthopedic implants (such as acetabular cups) to match the human bone surface, Debaolong uses five – axis CNC to machine titanium alloy TC4, combined with electrochemical polishing (Ra ≤0.2μm), increasing the yield rate from 75% to 98%, meeting FDA standards.

4.2 New Energy Vehicle Field

In the mass production of motor housings (aluminum alloy 6061), Debaolong’s automated production line combined with a horizontal machining center completes the whole process from blank to inspection in 4 hours, with a single – shift production capacity of 200 pieces/8 hours, reducing costs by 20%.

4.3 Aerospace Field

For Inconel 718 turbine blades made of superalloy, Debaolong’s Mikron high – speed machining center (24,000rpm) combined with high – pressure cooling reduces the processing cycle from 12 hours to 6 hours, and extends the tool life by 50%.

Conclusion

Debaolong Seiko has established a benchmark in various industries with its profound understanding and innovative application of CNC machining technology. From technical definition to practice, CNC machining is promoting the manufacturing industry towards high – precision, high – efficiency, and high – flexibility. Debaolong is willing to explore the future of intelligent manufacturing with industry colleagues.