The application of 3D printing technology in the medical field has undoubtedly brought unprecedented innovations, breakthroughs, and rapid industry growth. Once regarded as a cutting-edge manufacturing technology, it has now become an indispensable tool in the medical industry. 3D printing technology boasts significant advantages that are particularly critical and impactful in the medical field, including speed, versatility, a wide range of material options, personalized customization, repeatability, and the ability to manufacture highly complex components.

3D printing technology is widely used in the medical industry, covering the production of personalized prosthetics and orthotics, medical implants, customized anatomical models for surgical preparation, anatomical research models, medical auxiliary tools, medical device prototypes, surgical instruments, and general medical equipment, among other areas.

Requirements for Materials Used in the Medical Industry

While 3D printing technology is highly versatile and compatible with various plastics, elastomers, and metal materials, it is important to note that not all 3D printing materials are suitable for manufacturing medical products. The medical industry has extremely strict requirements for materials. Below are the key characteristics that medical-grade 3D printing materials must possess:

Biocompatibility

For materials used in manufacturing implants and internal medical devices, excellent biocompatibility is a primary requirement. This means these materials must cause no adverse reactions when in contact with the human biological system. This characteristic is particularly crucial for medical products that come into direct contact with human tissues, such as implants, dentures, organ/bone replacements, and pacemakers.

Sterilizability

Given the extremely high hygiene standards in the medical industry, sterilization is indispensable. Therefore, medical 3D printing materials must be sterilizable to ensure they remain clean after multiple uses and prevent cross-infection.

Bioavailability

For body part substitutes such as prosthetics, dentures, implants, and artificial organs, meeting biocompatibility alone is insufficient. They also need to possess physical properties similar to the original body parts. For example, bone substitute materials need to be hard and strong to ensure adequate compressive strength, while materials used to print human ears must be relatively soft to provide a more comfortable experience.

It is important to emphasize that material requirements vary across different applications.

Specific Materials and Their Applications

PA 12 (Nylon)

This is a widely used material that is lightweight, corrosion-resistant, and chemically resistant. It offers excellent tensile and impact strength, combining toughness and flexibility. Nylon PA12 can be sterilized through various methods, including ethylene oxide, chemical sterilization, gamma ray irradiation, gas plasma, and steam autoclaving. Using MJF (Multi-Jet Fusion) or SLS (Selective Laser Sintering) 3D printing technologies, nylon PA12 can be precisely shaped. As a medical-grade material, PA12 has obtained ISO certification and USP I-IV grade certification, making it widely used in prosthetics manufacturing.

Polyetherimide (ULTEM 1010)

Among FDM (Fused Deposition Modeling) thermoplastics, ULTEM 1010 stands out for its top-tier strength, heat resistance, and chemical resistance. It also exhibits excellent biocompatibility and can be sterilized via gamma irradiation, ethylene oxide, gas plasma, and high-pressure steam. Therefore, ULTEM 1010 is often used to print surgical guides, prototypes, prosthetics, and other medical products.

Silicone (Sil 30)

Silicone is a heat-resistant, tear-resistant, highly elastic biocompatible elastomer

It is commonly used to manufacture wearable devices that come into contact with the skin, such as breathing masks, and can also be used to print implants. Silicone can be printed using Carbon DLS (Digital Light Synthesis) 3D printing technology.

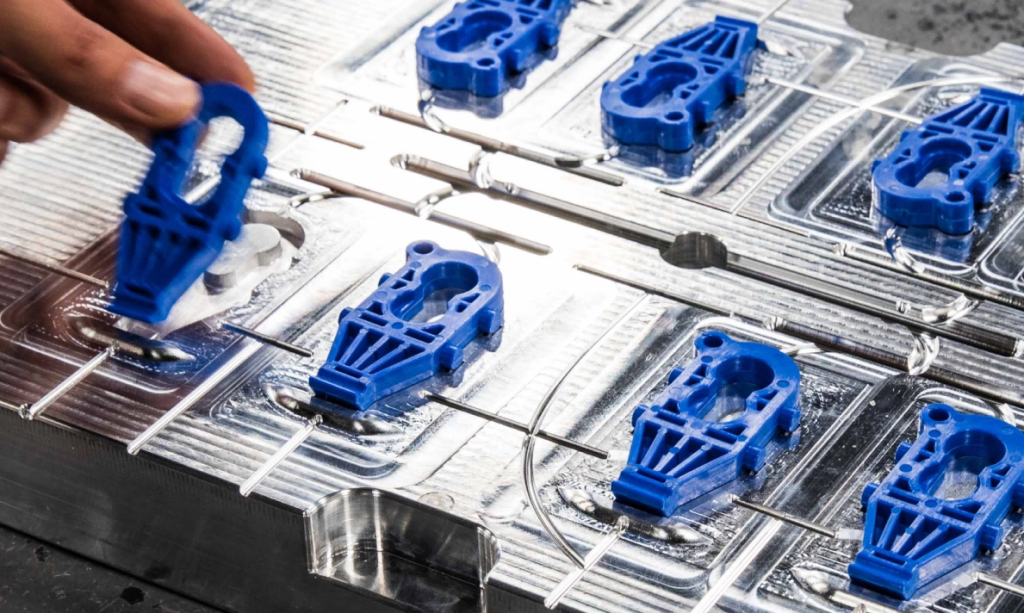

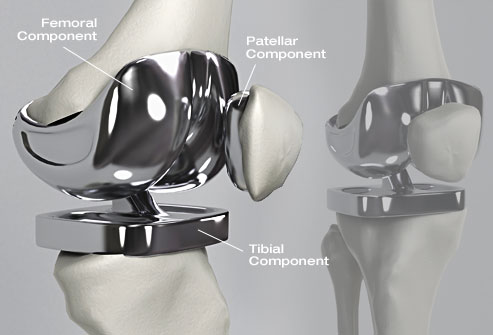

Titanium (Ti6Al4V)

Titanium knee replacement

Titanium is undoubtedly one of the most highly regarded metals in the medical industry, owing to its numerous excellent properties, particularly its high similarity to human bone. Titanium offers extremely high strength, outstanding heat resistance and hardness, good corrosion resistance, and non-reactivity. Additionally, it can be sterilized through various methods and exhibits high biocompatibility.

In the medical industry, titanium is widely used to manufacture customized orthopedic implants, such as bone and joint replacements, dental implants, and cranial plates. It is also used to produce various medical tools. These applications are supported by DMLS (Direct Metal Laser Sintering) technology, which enables titanium materials to be printed with high precision and quality.

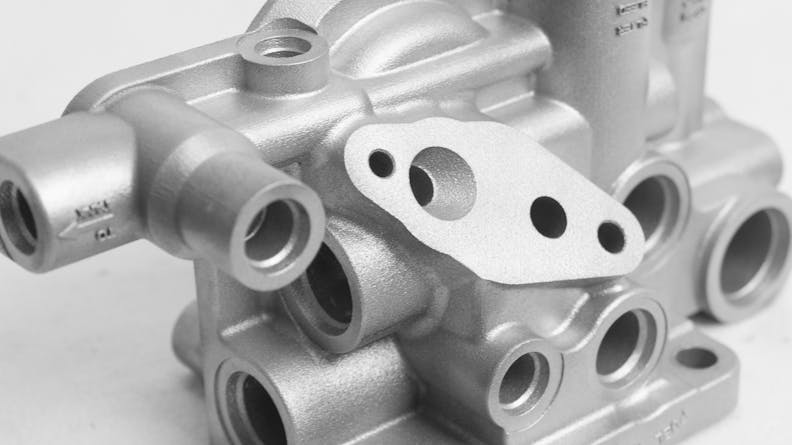

Stainless Steel (17-4PH)

Stainless Steel Surgical Tools

Stainless steel is a high-strength metal with biocompatibility that can be sterilized using multiple methods. However, its corrosion resistance is relatively limited, especially for implants, where its performance is inferior to titanium and cobalt-chromium alloys. Nevertheless, stainless steel remains an ideal choice for surgical tools and temporary implants. Printing stainless steel using DMLS technology is also relatively cost-effective compared to titanium and cobalt-chromium alloys.

Conclusion

Debaolong Seiko is committed to providing the medical industry with fast, reliable, and high-precision 3D printing services, covering a variety of materials such as thermoplastics, elastomers, and metals. We also offer multiple post-processing operations to ensure products meet the highest quality standards.

Regardless of your requirements in terms of quantity, precision, complexity, or delivery time, we have the capability to fulfill them. We look forward to collaborating with you to jointly drive innovation and development in the medical industry.