In CNC machining, the costs of different processing projects vary widely. The cost of a CNC machining project is determined by many factors. In most project plans, cost is an important factor to be considered. Therefore, we recommend that you understand the various factors of CNC machining and their impact on costs.

This article will help you understand the main factors affecting CNC machining costs, so that your project can minimize costs as much as possible.

Factors Influencing CNC Machining Costs

The most critical factors affecting the cost of CNC machined parts can be categorized into equipment, materials, design, production volume, and finishing processes.

Equipment and Machinery

Equipment costs are incurred before the machining process begins. However, equipment and machinery belong to production preparation costs and ultimately affect the cost of the machining plan. The higher the cost to acquire, operate, and maintain a machine, the more expensive the parts manufactured by that machine will be.

How to Choose Different CNC Machine Tools

CNC machining encompasses various processes, including drilling, boring, turning, milling, etc. Most of these can be achieved through CNC lathes or CNC milling machines.

Another consideration is the efficiency of the lathe itself. CNC lathes have undergone multiple iterations over the years. Early CNC lathes and computer numerical control lathes are completely incomparable to the advanced modern CNC machines used today. Modern machines are faster and more efficient, which will make part production cheaper in the long run.

How to Choose Different CNC Machining Tools

Additionally, the cost of cutting tools affects the overall equipment cost. The material, coating, and geometry of the tool all influence this cost. For example, carbide tools are harder, more heat-resistant, and can withstand high-speed operations, costing twice as much as steel tools.

Why Do CNC Milling Machines Cost More?

Due to their more complex movable parts, milling machines are generally more expensive than lathes. Milling machines are more difficult to assemble, operate, and maintain but can perform more complex operations. Therefore, CNC milling machines are generally more expensive to operate than other machine tools.

Milling machines come in different types, varying in complexity and capability. The more axes a milling machine has, the higher its price. Most modern CNC machines have three or five axes. Although five-axis machines can produce highly complex geometries more accurately and quickly (thus requiring less machining time), they are generally much more expensive than their three-axis counterparts.

Production Preparation Costs

Production preparation costs include all expenses incurred in preparing for actual machining. All CNC machined parts start as 3D models, and design experts need to use professional CAD (Computer-Aided Design) software to design these 3D models. The resources required to develop a final production-ready 3D model account for a significant portion of production preparation costs.

Production preparation costs also include design optimization and all related costs for preparing the model for production using professional CAM (Computer-Aided Manufacturing) software.

Materials

Impact of Material Prices on CNC Machining Costs

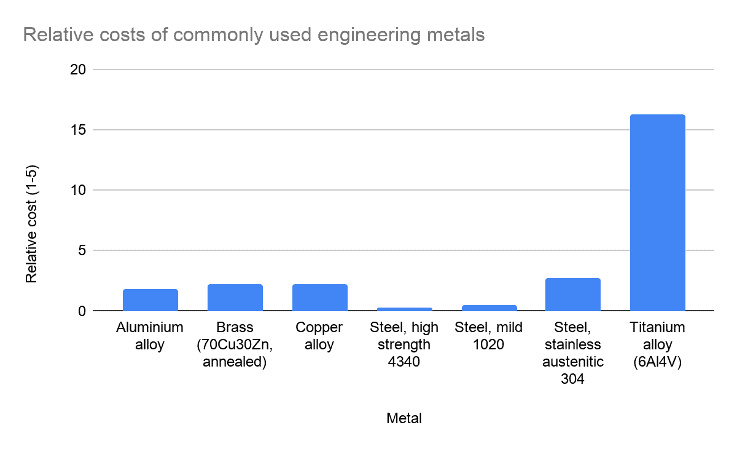

The materials required to make a part are one of the most critical cost-influencing factors. Many costs are associated with the material to be machined. First and foremost is the cost of the material itself. Materials are priced differently depending on their availability, material properties, and overall production costs.

Metal materials are typically more expensive than other materials. The following chart describes the relative prices of some common engineering metals. Note that metal prices fluctuate, and accurate prices may vary by region. The table below is for relative price reference.

Comparison of Metal Raw Material Cost Differences

Key Factor: Machinability of Materials

In addition to material costs, machinability is another important cost-determining factor. Materials with low machinability take more time and effort to process, and in CNC machining, time is money. The cost of a machined part is directly proportional to the time spent machining it. Difficult-to-machine materials also consume more resources, such as cutting fluids, electricity, and cutting tools.

Debaolong Seiko can provide various machining materials, including metals, plastics, and rubber-based materials.

Design and Geometry

Improving CAD Designs for CNC Machining

The design and shape of a part greatly influence CNC machining costs.

As a rule of thumb: the more complex a part is, the more expensive it is to manufacture. Complex parts may require more advanced machines, longer machining times, multiple processing and assembly steps, more resources, and more meticulous quality inspections—all of which affect part costs.

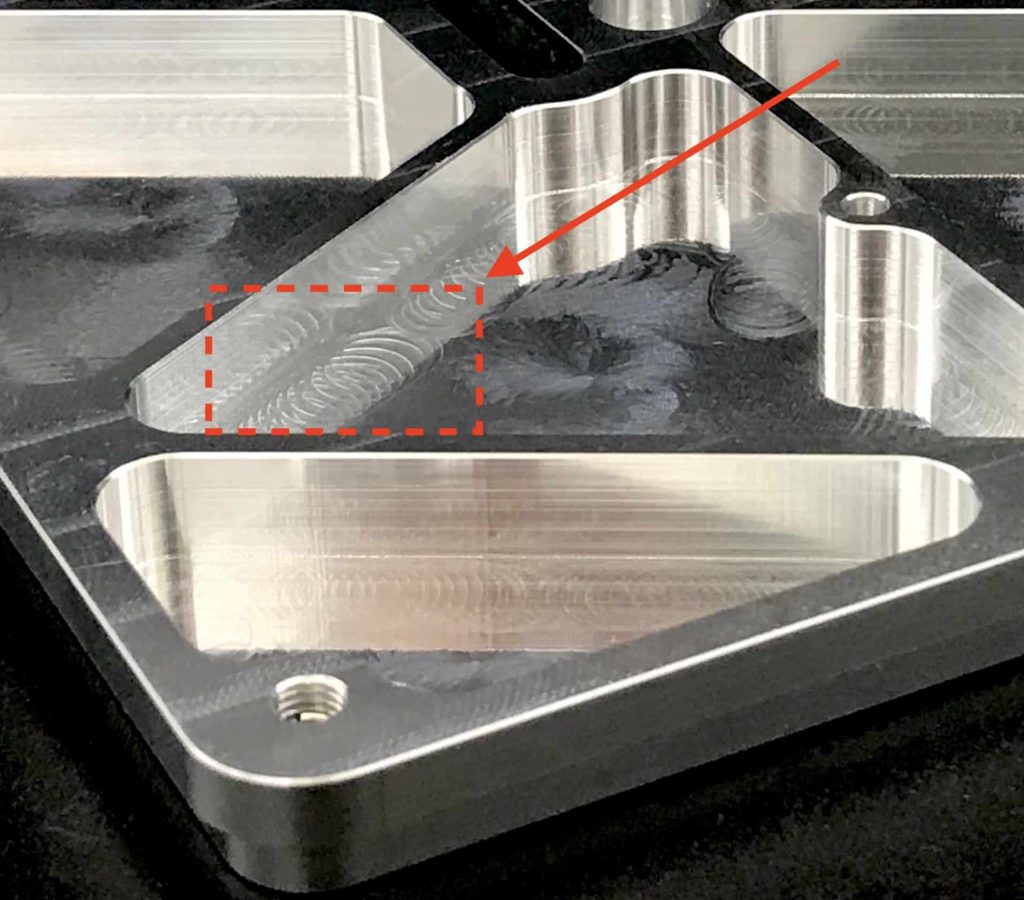

In CNC machining, specific part features and designs will inevitably lead to increased costs, including sharp internal corners, thin walls, deep cavities, non-standard hole sizes, engraving, etc. These and other high-cost part features we have summarized significantly impact costs and should be avoided unless necessary. Additionally, specific design requirements, such as surface roughness or tolerance levels, may require multiple processing and quality inspection steps.

Moreover, theoretically, larger parts cost more because they require more raw materials, manufacturing resources, and time.

Production Volume

Larger Batches, Lower Costs

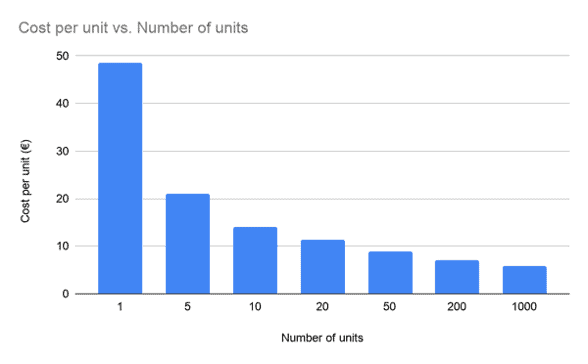

As the number of parts increases, the unit cost of manufacturing a set of identical parts decreases. This proportional reduction in cost is attributed to the elimination of repeated production preparation costs. Preparation costs such as CAD design, CAM preparation, and machine setup are one-time expenses for the same set of parts to be manufactured.

Using data from our instant quotation engine, you can compare the relationship between the number of parts and unit cost in the table below. The example part is made of aluminum EN AW-6061 / 3.3211 / Al-Mg1SiCu.

Comparison of Order Quantity and Cost

The table above confirms that the unit cost of a single part is inversely proportional to the number of parts manufactured. The unit cost for a batch of 1,000 pieces is approximately 88% lower than that for a single part.

Surface Processing Techniques

Parts produced by CNC machining can be used directly. However, some specific applications require parts to undergo post-processing steps, such as heat treatment, surface finishing, and painting, to improve their performance, characteristics, and aesthetics. All these surface processing techniques will increase part manufacturing costs.