Since the Industrial Revolution, many manufacturing technologies have been developed. According to different processes, these technologies can be divided into different categories, mainly three categories: additive manufacturing, subtractive manufacturing, and formative manufacturing. This article will explore two of them – the processes, advantages, disadvantages, and differences between subtractive manufacturing and additive manufacturing.

What is Subtractive Manufacturing

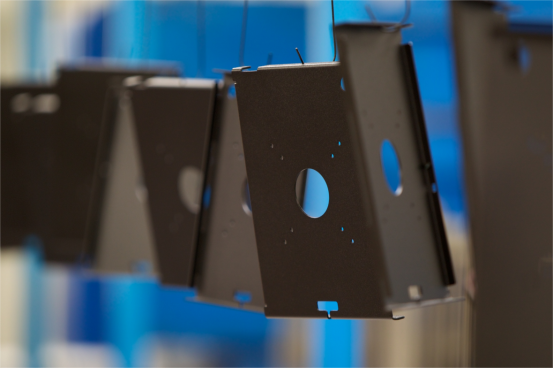

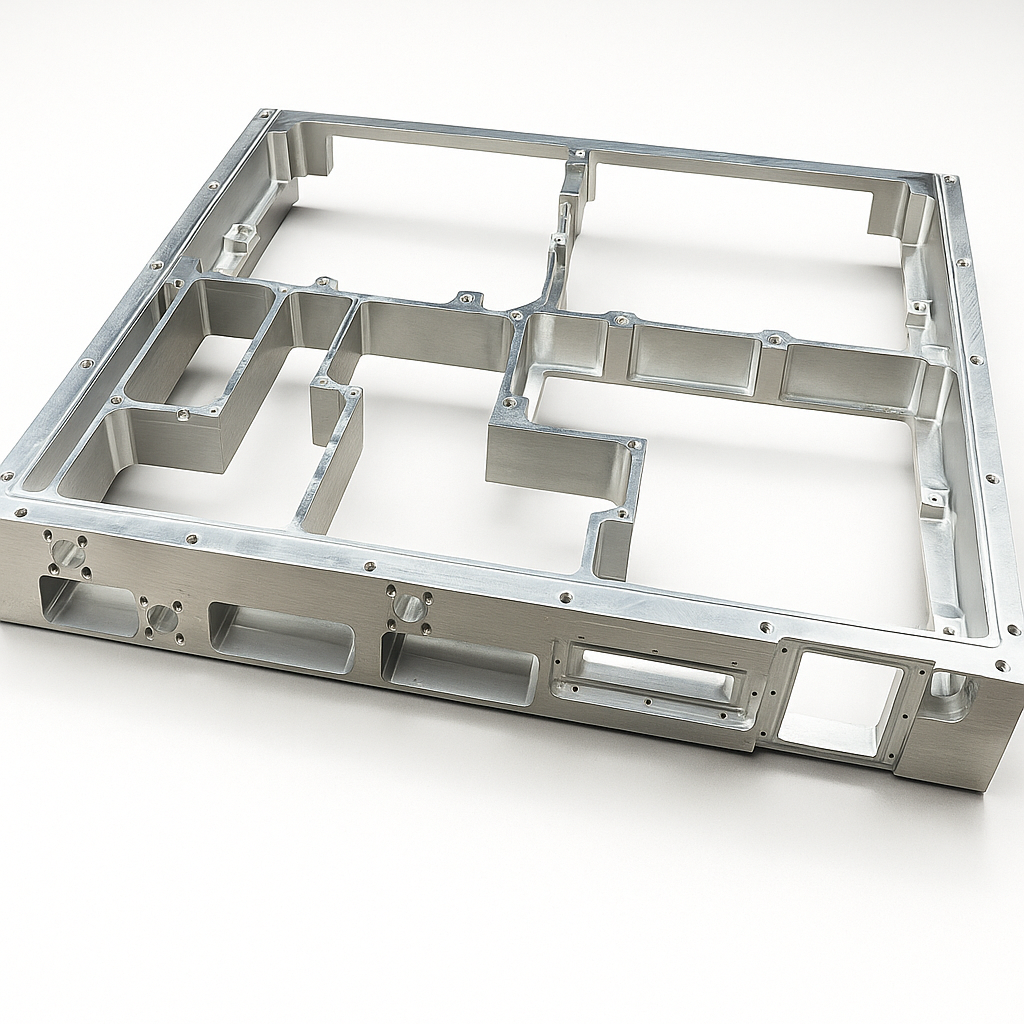

Subtractive manufacturing creates objects by gradually removing material from a solid block or plate. Material removal is achieved through cutting, drilling, boring, or grinding. These processes can be performed manually, but they are usually completed using computer numerical control (CNC) technology. A popular subtractive manufacturing process today is CNC machining.

In CNC machining, computer numerical control cutting tools achieve the desired geometry by mechanically removing material. The process involves using computer-aided design (CAD) software to design the machining model and computer-aided manufacturing (CAM) software to guide how the CNC machine tool precisely removes material. The three main machining processes for material removal based on 3D models are turning, drilling, and milling. Other subtractive manufacturing processes include laser cutting, waterjet cutting, electrical discharge machining (EDM), and plasma cutting, which are mainly used for 2D machining.

Advantages of Subtractive Manufacturing

- Suitable for multiple materials, including metals, plastics, plastic composites, and even wood.

- Can be used to obtain almost any geometry, such as planes, holes, cylinders, threads, slots, etc.

- Can achieve high precision, with a tolerance of approximately 0.025 millimeters.

- Can obtain a smooth surface finish.

Limitations of Subtractive Manufacturing

- More material waste, as chips will be discarded. Even if these chips can be recycled, they are still waste.

- The processing time for each part is longer than that of additive manufacturing and formative manufacturing methods.

What is Additive Manufacturing

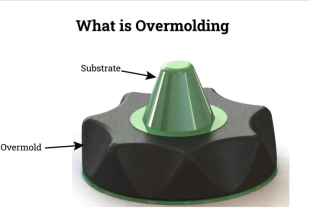

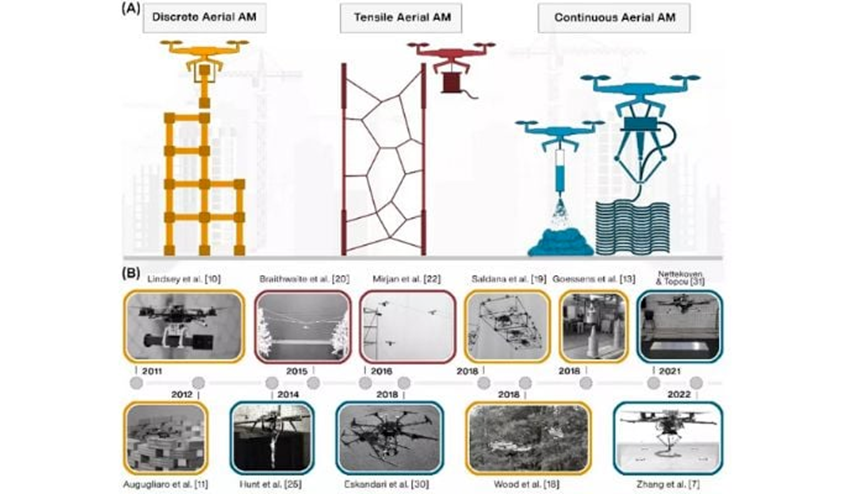

Additive manufacturing is a process of manufacturing components from 3D model data by stacking materials layer by layer, contrary to subtractive manufacturing and formative manufacturing methods. Although most global applications of additive manufacturing currently focus on polymer-based systems, there is increasing activity and interest in manufacturing metal components.

Additive manufacturing is widely known as 3D printing, which is achieved using 3D printer equipment.

The term “3D printing” covers a range of different processes that vary according to raw materials and energy sources. However, some common basic steps exist in all operations:

- First, design the CAD model of the part to be printed.

- Then, use special slicing software to slice the model into multiple cross-sectional layers.

- According to the technology used, the 3D printer will start to melt, fuse, or cure the raw materials and stack them layer by layer until the desired geometry is formed. Raw materials can be powders, wires, plates, or liquids.

3D printing processes include Stereolithography (SLA), Selective Laser Sintering (SLS), HP Multi-Jet Fusion (MJF), Fused Deposition Modeling (FDM), Selective Laser Melting (SLM), etc.

Advantages of Additive Manufacturing

- Eliminates waste, so it is highly efficient.

- Faster speed from design to production compared to other methods.

- Can easily manufacture complex and intricate designs.

Limitations of Additive Manufacturing

- Limited types of available materials compared to other manufacturing processes.

- Higher costs when processing metals.

- Not suitable for mass production.

Comparison Between Additive Manufacturing and Subtractive Manufacturing

| Aspect | Additive Manufacturing | Subtractive Manufacturing |

|---|---|---|

| Achievable Complexity | Can produce components with highly complex and intricate geometries, even better than five-axis CNC machining. | More suitable for relatively simple geometries. |

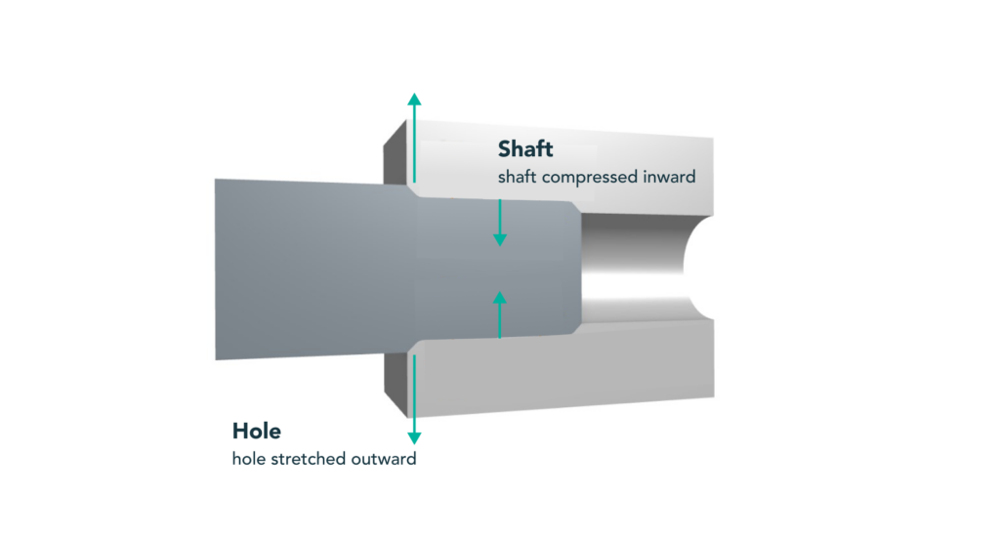

| Producible Features | Cannot effectively produce features such as holes and threads. | Can effectively create holes and threaded parts. |

| Component Performance | Produced components may have insufficient mechanical properties. Due to layer-by-layer stacking, structural weaknesses may occur between layers, affecting specific performance. | Produced components have excellent mechanical and thermal properties. |

| Precision | Lower achievable dimensional accuracy. More precise additive manufacturing processes such as Selective Laser Melting (SLM) or Direct Metal Laser Sintering (DMLS) can produce components with tolerances as tight as 0.100 millimeters. | Can achieve higher dimensional accuracy, with tolerances as tight as 0.025 millimeters. |

| Production Materials | Mainly used for plastics, and also suitable for a small number of metals. | Suitable for a wide range of materials, including plastics, metals, wood, foam, glass, and stone. |

| Post-Processing | Produced components all require post-processing. | Produced components do not necessarily require post-processing. |

| Setup | Requires less setup and shorter time from design to production. After designing the CAD model of the component and converting it, only the raw materials need to be set up, and the rest is done by the 3D printer. | The setup process requires more time and effort. For example, in CNC machining, after designing the CAD model and converting it into G-code, multiple aspects and parameters of the CNC machine need to be set up, including placing the workpiece on the table, selecting and preparing appropriate cutting fluids, selecting and fixing cutting tools, and setting correct speeds, feeds, and cutting depths. |

| Scalability | Production costs are proportional to the number of productions. As the number of productions increases, production costs rise significantly. | Production costs are inversely proportional to the number of productions. As the number of productions increases, production costs decrease. |

| Speed and Cost | Faster and cheaper for small geometric components, plastics, and low-volume production. | Faster and cheaper for relatively large components, metals, and high-volume production. |

Selection Between Additive Manufacturing and Subtractive Manufacturing

Both additive manufacturing and subtractive manufacturing are suitable for prototyping. However, 3D printing is more suitable for prototyping with plastics, while metal prototyping is more suitable for additive manufacturing. For finished products, subtractive manufacturing is more appropriate because components produced by subtractive manufacturing usually do not require post-processing and have better mechanical properties.

For low-volume production, such as 1-10 identical components, if polymer materials are used, 3D printing is more appropriate because the cost is lower for this quantity. For producing 10-10,000 identical components, subtractive manufacturing is more cost-effective. For production quantities exceeding 10,000, formative manufacturing processes should be considered.

Additive manufacturing is more suitable for producing smaller-sized components, while subtractive manufacturing is more suitable for larger-sized components.

Materials such as metals, wood, glass, stone, and foam are either very expensive or cannot be manufactured using additive manufacturing, so these materials require subtractive manufacturing. On the other hand, difficult-to-process materials such as flexible thermoplastic polyurethane (TPU) and metal superalloys can be manufactured by 3D printing.

Additive manufacturing is more cost-effective than subtractive manufacturing for low-volume plastic products. However, for metals, Selective Laser Melting (SLM) costs about 100% more than CNC machining.

In summary, additive manufacturing is more suitable for prototyping and low-volume production of small, highly complex components made of plastics. Subtractive manufacturing is more suitable for mass production of relatively simple, large components made of various materials.

Debaolong Seiko provides subtractive manufacturing and additive manufacturing services: 3D printing, sheet metal processing, and CNC machining.

Upload your drawings to get a real-time quote!