Aluminum is one of the most commonly used materials in current mechanical processing. In fact, the frequency of CNC machining processes for aluminum materials is second only to steel.

In its high-purity form, the chemical element aluminum is soft, ductile, non-magnetic, and has a silvery-white appearance. However, this element is not used solely in its pure form. Aluminum is often cast into alloys with various elements such as manganese, copper, and magnesium to form various aluminum alloys with significantly improved properties. Common machined aluminum alloys and their grades under different standards can be found here.

Advantages of Using Aluminum for CNC Machined Parts

Although there are countless aluminum alloys with varying properties, some basic characteristics apply to all aluminum alloys:

Machinability

Aluminum can be rapidly formed, manufactured, and processed through various treatments. It is soft, easy to cut, inexpensive, and requires less force to machine than steel, allowing it to be quickly and easily cut by machine tools. These characteristics are significant advantages for both machinists and clients ordering parts. Additionally, aluminum’s excellent machinability means it is less prone to deformation during processing. Due to its ability to allow CNC machines to achieve higher tolerance levels, it offers greater precision.

Strength-to-Weight Ratio

Aluminum has a density approximately one-third that of steel, making it relatively lightweight. Despite its light weight, aluminum has high strength. This combination of strength and weight is known as the material’s strength-to-weight ratio. Aluminum’s high strength-to-weight ratio makes it suitable for many industrial components, such as those in the automotive and aerospace industries.

Corrosion Resistance

Aluminum is resistant to scratches and corrosion in normal marine and atmospheric environments. This property can be further enhanced through anodizing. It should be noted that different grades of aluminum have varying corrosion resistance; conventional CNC machining grades generally exhibit stronger resistance.

Low-Temperature Performance

Most materials lose some of their desirable properties below freezing. For example, carbon steel and rubber become brittle at low temperatures. Aluminum, however, maintains its softness, ductility, and strength in extremely low temperatures.

Electrical Conductivity

Pure aluminum has an electrical conductivity of approximately 37.7 million Siemens per meter at room temperature. While aluminum alloys have lower conductivity than pure aluminum, they are still sufficient for use in electronic components. On the other hand, if electrical conductivity is not an ideal property for a machined part, aluminum may not be the suitable material.

Recyclability

Since CNC machining is a subtractive manufacturing process, it generates a large amount of chips (waste material). Aluminum is highly recyclable and requires relatively little energy, effort, or cost to recycle. This makes it popular among those looking to recoup costs or reduce material waste, and it also makes aluminum a more environmentally friendly machining material.

Anodizing Feasibility

Anodizing is a surface treatment process that improves material wear and corrosion resistance, and it is easily achievable for aluminum. This process also makes it easier to color machined aluminum parts.

Popular Aluminum Alloys in CNC Machining

Based on Debaolong Seiko’s experience, the following five aluminum grades are commonly used in CNC machining:

1. EN AW-2007 / 3.1645 / AlCuMgPb

Other designations: 3.1645; EN 573-3; AlCu4PbMgMn

This aluminum-copper alloy has copper as its primary alloying element (4%–5%). It is a short-chip alloy that is durable, lightweight, and functional, with high mechanical properties similar to AW 2030. It is suitable for tapping, heat treatment, and high-speed machining. All these properties make EN AW-2007 widely used in manufacturing mechanical parts, bolts, rivet nuts, screws, and threaded rods. However, this aluminum grade has low weldability and corrosion resistance, so anodizing is recommended after part machining for protection.

2. EN AW-5083 / 3.3547 / Al-Mg4.5Mn

Other designations: 3.3547; Alloy 5083; EN 573-3; UNS A95083; ASTM B209; AlMg4.5Mn0.7

Alloy AW 5083 is known for its excellent performance in extreme environments. It contains magnesium and trace amounts of chromium and manganese, exhibiting very high corrosion resistance in chemical and marine environments. Among all non-heat-treatable aluminum alloys, AW 5083 has higher strength, which it maintains even after welding. Although this alloy is not suitable for use at temperatures above 65°C, it performs well at low temperatures.

Due to its range of ideal properties, AW 5083 is used in numerous applications, including cryogenic equipment, marine applications, pressure equipment, chemical applications, welded structures, and vehicle bodies.

3. EN AW-5754 / 3.3535 / Al-Mg3

Other designations: 3.3535; Alloy 5754; EN 573-3; UNS A95754; ASTM B 209; Al-Mg3

AW 5754 is a high-aluminum-content aluminum-magnesium alloy that can be rolled, forged, and extruded. It is also a non-heat-treatable alloy, strengthened through cold working but with lower ductility. Additionally, this alloy has excellent corrosion resistance and high strength. Given these properties, it is no surprise that AW 5754 is one of the most popular aluminum grades for CNC machining. It is commonly used in welded structures, flooring, fishing gear, vehicle bodies, food processing, and rivets.

4. EN AW-6060 / 3.3206 / Al-MgSi

Other designations: 3.3206; ISO 6361; UNS A96060; ASTM B 221; AlMgSi0.5

This aluminum alloy is made with magnesium and silicon. It is heat-treatable, has medium strength, good weldability, and formability, and is highly corrosion-resistant (further improved through anodizing). EN AW 6060 alloy is commonly used in construction, food processing, medical equipment, and automotive engineering.

5. EN AW-7075 / 3.4365 / Al-Zn6MgCu

Other designations: 3.4365; UNS A97075; Al-Zn6MgCu

In this aluminum grade, zinc is the primary alloying element. Although EN AW 7075 has moderate machinability, poor cold-working formability, and is unsuitable for fusion welding, it has a high strength-to-weight ratio, excellent tolerance in atmospheric and marine environments, and higher strength than some steel alloys. This alloy is used in a wide range of applications, including hang gliders and bicycle frames, climbing equipment, weapons, and mold manufacturing.

6. EN AW-6061 / 3.3211 / Al-Mg1SiCu

Other designations: 3.3211; UNS A96061; A6061; Al-Mg1SiCu

This alloy has magnesium and silicon as its main alloying elements, with trace amounts of copper. It is a high-strength alloy with a tensile strength of up to 180 MPa, making it ideal for high-load-bearing structures such as scaffolding, railway carriages, machinery, and aerospace components.

7. EN AW-6082 / 3.2315 / Al-Si1Mg

Other designations: 3.2315; UNS A96082; A-SGM0.7; Al-Si1Mg

This alloy is typically produced by rolling and extrusion, offering medium strength, excellent weldability, and thermal conductivity, as well as high resistance to stress corrosion cracking. Its tensile strength ranges from 140–330 MPa, and it is widely used in marine construction and container manufacturing.

CNC Machined Aluminum Parts Produced by Debaolong Seiko

CNC Machining Processes for Aluminum

Several CNC machining processes can be used to machine aluminum, including:

CNC Turning

In CNC turning operations, the workpiece rotates while a single-point cutting tool remains stationary along the axis. Either the workpiece or the tool feeds against the other via the machine tool to achieve material removal.

CNC Milling

CNC milling is a very common process for machining aluminum parts. These processes involve the rotation of multi-point cutting along the axis while the workpiece remains stationary. Cutting and subsequent material removal are achieved through feed movements of the workpiece, the cutting tool, or both, and can be performed along multiple axes.

Pocket Milling

Also known as slot milling, this is a form of CNC milling used to machine a hollow recess in a part.

Face Machining

Face machining involves creating a flat cross-section on a workpiece surface using face turning or face milling.

CNC Drilling

CNC drilling is the process of creating a hole in a workpiece. In this process, a multi-point rotating cutting tool of a specific size moves linearly perpendicular to the surface to be drilled, effectively creating the hole.

Tools for Machining Aluminum

Many factors influence the selection of tools for CNC machining of aluminum:

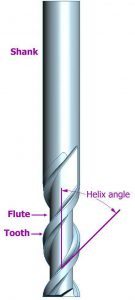

Tool Design

The shape of a tool affects its efficiency in machining aluminum. One factor is the number of flutes on the tool. To avoid difficulty in chip evacuation at high speeds, cutting tools for CNC machining of aluminum should have 2–3 flutes. Too many flutes mean narrower chip evacuation channels, which can cause large chips from aluminum alloys to become stuck. Use a 2-flute tool when cutting forces are low and chip evacuation is critical for the entire process. For a balance between chip evacuation and tool strength, use a 3-flute tool.

Helix Angle

The helix angle is the angle between the tool’s central axis and the line along the cutting edge. It is an important feature of cutting tools. Although a larger helix angle clears chips faster from the part, it increases friction and heat during cutting. In high-speed CNC machining of aluminum, this can cause chips to weld to the tool surface. On the other hand, a smaller helix angle generates less heat but may not clear chips effectively. For rough machining of aluminum, a helix angle of 35° or 40° is suitable, while a 45° helix angle is recommended for finish machining.

Relief Angle

The relief angle is another critical factor for tool performance. Excessive angle can cause the tool to dig into the workpiece and chatter, while too small an angle can cause friction between the tool and the workpiece. The optimal relief angle for CNC machining of aluminum is between 6° and 10°.

Tool Material

Carbide is the preferred material for cutting tools in aluminum machining. Since aluminum is a soft material, cutting tools must not be too hard but must maintain sharp edges. Carbide tools achieve this through two key factors: alloy grain size and binder ratio. While larger grain sizes result in harder materials, smaller grain sizes ensure greater toughness and impact resistance—desirable characteristics. Smaller grains allow cobalt to form a fine grain structure and material strength.

However, cobalt reacts with aluminum at high temperatures, forming built-up edges (BUE) on the tool surface. To minimize this reaction, it is critical to use carbide tools with an appropriate cobalt content (2–20%) while maintaining required strength. Carbide tools generally withstand the high speeds of aluminum machining better than steel tools. In addition to tool material, coatings are an important factor in cutting efficiency. Zirconium nitride (ZrN), titanium diboride (TiB₂), and diamond-like carbon (DLC) coatings are suitable for tools used in aluminum machining.

Feed Rate and Speed

Cutting speed is the rotational speed of the cutting tool. Aluminum can withstand very high cutting speeds, so the cutting speed for aluminum alloys depends on the limits of the machine tool used. This speed should be as fast as practically possible for aluminum CNC machining, as it reduces the likelihood of built-up edge formation, saves time, lowers part temperature, improves chip breakage, and enhances finish quality. The exact speed used varies by aluminum alloy and tool diameter.

Feed rate is the distance the workpiece or tool moves per revolution of the tool. Feed rate selection depends on the desired part finish, strength, and rigidity. Rough cutting requires a feed rate of 0.15–2.03 mm/rev, while finish cutting requires 0.05–0.15 mm/rev.

Cutting Fluid

Even with aluminum’s excellent machinability, never cut it dry, as this promotes built-up edge formation. Suitable cutting fluids for aluminum CNC machining are oil-soluble emulsions and mineral oils. Avoid cutting fluids containing chlorine or active sulfur, as these elements can contaminate aluminum.

Post-Machining Processes

After machining an aluminum part, specific processes can be applied to enhance its physical, mechanical, and aesthetic properties. Common processes include:

Bead Blasting and Sandblasting

Bead blasting is a decorative finishing process in which small glass beads are sprayed onto the machined part under high pressure to effectively clean the material and ensure a smooth surface, giving aluminum a smooth or matte finish. The main operating parameters for bead blasting are glass bead size and air pressure. This process is suitable only when part dimensional tolerances are not critical.

Other processes include polishing and painting.

Coating

This process involves coating aluminum parts with materials such as zinc, nickel, or chromium, which can be achieved through electrochemical reactions to improve part finish.

Anodizing

Anodizing is an electrochemical process in which an aluminum part is immersed in a dilute sulfuric acid solution, and a voltage is applied between the positive and negative electrodes. This process effectively converts the part’s exposed surface into a hard, non-reactive aluminum oxide coating. The density and thickness of the resulting coating depend on the solution concentration, anodizing time, and current. Anodizing can also be used to color parts.

Powder Coating

Powder coating involves applying colored polymer powder to parts using an electrostatic spray gun, followed by curing the parts at 200°C. Powder coating improves strength, wear resistance, corrosion resistance, and impact resistance.

Heat Treatment

Parts made from heat-treatable aluminum alloys undergo heat treatment to improve their mechanical properties.

Industrial Applications of CNC Machined Aluminum Parts

As mentioned, aluminum alloys have many desirable properties, making CNC machined aluminum parts indispensable in many industries, including:

- Aerospace: Due to aluminum’s high strength-to-weight ratio, many aircraft components are made from machined aluminum.

- Automotive: Similar to aerospace, many automotive components such as drive shafts are made from aluminum.

- Electrical: CNC machined aluminum parts are often used as electronic components in household appliances due to their high electrical conductivity.

- Food/Pharmaceuticals: Aluminum parts do not react with most organic substances, making them essential in the food and pharmaceutical industries.

- Sports: Aluminum is used to make sports equipment such as baseball bats and whistles.

- Cryogenics: Aluminum maintains its mechanical properties below freezing, making aluminum parts popular in low-temperature applications.