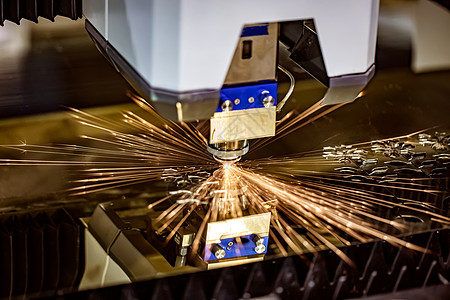

Laser cutting is a CNC cutting process that utilizes high-power lasers to cut materials. In this process, a high-density light beam is created by using electrical discharge to stimulate the laser material within a closed container. Optical devices are employed to focus the generated laser beam onto the workpiece, enabling effective cutting through melting, evaporation, or combustion. The movement of the laser beam is controlled by numerical control technology.

Types of Laser Cutters

Laser cutters primarily use three types of lasers: CO₂ (carbon dioxide), fiber, and YAG lasers.

| Laser Type | CO₂ (Carbon Dioxide) | Fiber | YAG |

|---|---|---|---|

| Advantages | • High energy efficiency • High power output ratio | • High speed • High precision • High efficiency | • Flexibility • Portability |

| Disadvantages | • Not suitable for thick metal plates | • [To be specified] | • [To be specified] |

| Applications | Well-suited for drilling, engraving, and cutting relatively thin materials | Suitable for cutting metal and non-metal materials | Suitable for various scenarios |

Materials for Laser Cutting

Laser cutting can be used to cut various materials such as paper, wood, metal, and rock, but it is widely applied in material removal for sheet metal processing and manufacturing, such as:

- Aluminum

- Steel

- Stainless steel

- Copper and other metals

Generally, laser cutters are highly suitable for cutting relatively thin sheets. The maximum thickness for aluminum can reach 15 mm, and for steel, it is 6 mm. They typically have a tolerance range of 0.2 to 0.1 mm.

Advantages and Limitations of Laser Cutting

Due to the high precision of laser cutting, laser-cut components usually require less post-processing. The heat-affected zone generated by the laser system is relatively small, reducing the need for subsequent heat treatment.

Compared with other cutting processes, laser cutting offers higher precision than plasma cutting and greater flexibility in material applicability, though it is slightly inferior to waterjet cutting.

Laser cutting is the most widely used cutting method due to its broad material applicability, high precision, and the ability to perform both cutting and engraving (which waterjet cutting cannot achieve). Additionally, laser cutting is less costly than waterjet cutting.

Laser Cutting Costs

The cost of laser cutting varies significantly depending on the laser type and the selected material. The simplest way to obtain costs for your sheet metal processing project is to contact Debaolong Seiko, upload your CAD files, and get a real-time quotation