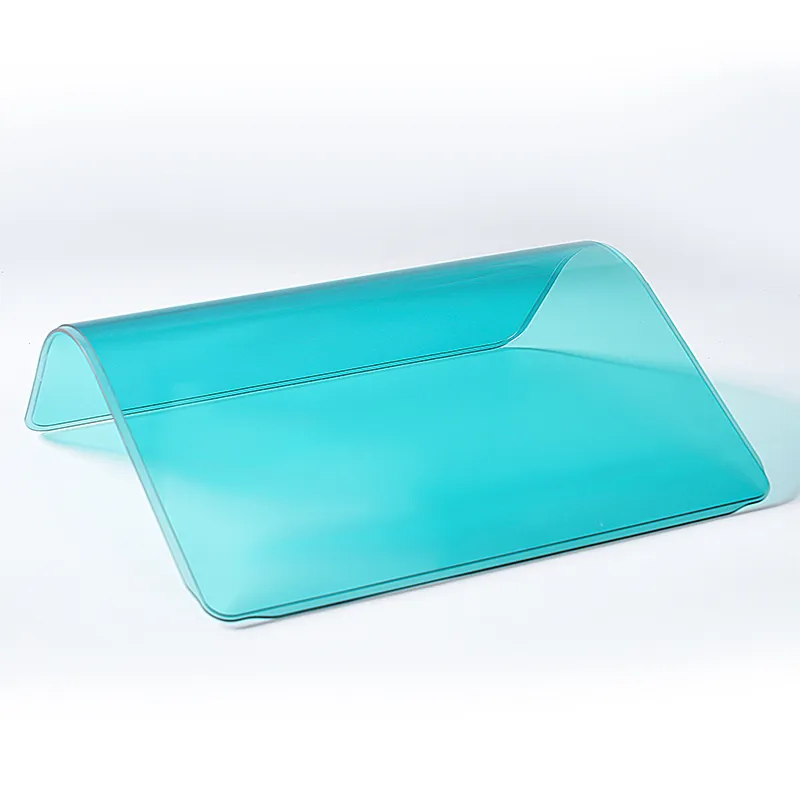

I. Definition of Acrylic CNC Machining

CNC stands for Computer Numerical Control. Acrylic CNC machining is a process that uses computer numerical control technology to perform precise machining operations such as cutting, engraving, drilling, and milling on acrylic materials (polymethyl methacrylate, PMMA). By following pre-programmed instructions, it controls the movement trajectory of the tool on acrylic plates or blocks to create complex-shaped products.

II. Characteristics of Acrylic Material

Advantages

- High Transparency: Light transmittance exceeds 92%, earning it the reputation of “plastic crystal.”

- Lightweight: With a density of approximately 1.18–1.19 g/cm³, it weighs only 50% of glass.

- Excellent Weather Resistance: Resistant to discoloration and aging when used outdoors, with good UV resistance.

- High Safety: More ductile than glass, less prone to shattering, and produces no sharp fragments when broken.

- Good Processability: Can be formed through various processes such as CNC, 3D printing, and injection molding.

Disadvantages

- Low Impact Strength: More fragile compared to polycarbonate (PC).

- Moderate Heat Resistance: Recommended long-term service temperature not exceeding 80°C.

- Limited Chemical Resistance: Easily eroded by organic solvents (e.g., alcohol, gasoline).

III. Application Fields of Acrylic CNC Machining

| Industry | Typical Applications |

|---|---|

| Optical & Automotive | Headlight lenses, taillight covers, dashboard panels, submarine observation windows, optical lenses (e.g., eyeglasses, non-disposable contact lenses) |

| Medical & Dental | Subcutaneous fillers, bone cement (fracture repair, joint replacement), dentures, medical device observation windows |

| Consumer Goods | Furniture decorative parts, electronic product casings (e.g., LCD TV panels), musical instrument components, sculptures, and artworks |

| Industrial & Architectural | Aquarium glass, hockey rink barriers, shatterproof partitions, signboards, advertising light boxes |

IV. Comparison of Acrylic Machining Processes: CNC vs. 3D Printing

| Process | Advantages | Limitations | Application Scenarios |

|---|---|---|---|

| CNC Machining | ① High precision (tolerance ±0.05mm) and good surface finish; ② Achieves perfect transparency; ③ Suitable for small-to-medium batches of high-quality parts. | ① Requires pre-fabricated plates/blocks, with low material utilization; ② Difficult to machine complex internal cavities. | Optical lenses, precision components, high-transparency products |

| 3D Printing | ① Rapid prototyping, suitable for complex geometries; ② No need for molds, low cost (for small batches). | ① Low light transmittance for transparent parts (FDM process); ② High surface roughness, requiring post-processing. | Prototyping, small-batch complex parts |

V. Comparison of Acrylic with Other Transparent Plastics

| Material | Transparency | Impact Resistance | Heat Resistance | Cost | Typical Applications |

|---|---|---|---|---|---|

| PMMA (Acrylic) | ★★★★★ | ★★☆☆☆ | ★★☆☆☆ | Medium | Optical lenses, transparent decorative parts |

| PC (Polycarbonate) | ★★★☆☆ | ★★★★★ | ★★★★☆ | High | Bulletproof glass, sports goggles, high-temperature components |

| ABS | ★☆☆☆☆ | ★★★☆☆ | ★★★☆☆ | Low | Home appliance casings, automotive interior parts |

VI. Precautions for CNC Machining Acrylic

- Tool Selection: Use sharp carbide tools (e.g., single-flute spiral milling cutters) to avoid material tearing.

- Cutting Parameters:

- Feed rate: 500–1500 mm/min (adjust according to thickness);

- Spindle speed: 10,000–24,000 rpm;

- Cutting depth: 0.5–2 mm/layer (to prevent material melting due to overheating).

- Cooling Method: Use compressed air for chip removal to avoid surface corrosion from cutting fluid residue.

- Clamping Method: Use vacuum chucks or special fixtures to reduce deformation caused by clamping force.

VII. Post-Processing Techniques

- Polishing:

- Manual Polishing: Gradually sand with 砂纸 (800#→2000#), combined with polishing compound and linen cloth, suitable for high-transparency parts.

- Flame Polishing: Pass a hydrogen-oxygen flame over the surface to melt the outer layer and form a smooth finish, suitable for non-precision parts.

- Surface Treatment:

- Sandblasting/Textured Painting: Increase surface roughness to achieve diffused reflection effects (e.g., lamp covers).

- Coloring/Coating: Apply color through spraying or vacuum coating while maintaining transparency.

VIII. Conclusion

Acrylic CNC machining has become a core process in industries such as optics, automotive, and medical fields, thanks to its high precision, transparency, and flexible forming capabilities. Despite limitations in impact resistance and heat resistance, its comprehensive performance still makes it a key player among transparent materials. By reasonably selecting process parameters and post-processing methods, the advantages of acrylic can be maximized to meet diverse industrial needs.

With many years of experience in processing acrylic products, Debaolong Seiko has also provided countless beautiful works for various industries. If you have acrylic products processing needs, please visit www.debaoloong.com, we are your always trustworthy friend and partner!