Titanium is used in aerospace, medical, and automotive industries due to its lightweight, excellent corrosion resistance, and high strength-to-weight ratio. However, machining titanium alloys is not straightforward because of their high hardness and the challenge of selecting appropriate processing techniques. Below are 10 different methods for cutting titanium and its alloys, including their processes, required tools, and specific advantages, which can help you choose the right method based on your needs.

Is Titanium Metal Easy to Cut?

Cutting titanium alloys is far from simple due to their reactive nature. The process must be carried out in a cool environment to prevent metal contamination and discoloration. Titanium’s low thermal conductivity reduces heat dissipation from the tool, shortening tool life. Various tools such as band saws, water jets, plasma cutters, and laser cutters can be used to cut titanium accurately and efficiently.

Can Tungsten Carbide Cut Titanium?

Yes, most cutting tools for titanium are made of tungsten carbide, which is divided into two categories: titanium carbide and tungsten carbide. These tools maintain their hardness within a specific temperature range. Different coatings (e.g., PVD) on tungsten carbide tools help dissipate heat and extend their service life. Fine or medium-grain carbides with low binder content are typically used in cutting processes.

Titanium Alloy Properties Table

Physical Properties

- Density: 4.5 g/cm³

- Melting Point: 1650–1670°C

- Boiling Point: 3260°C

Mechanical Properties

- Tensile Strength: 220 MPa

- Elastic Modulus: 116 GPa

- Hardness (Brinell): 70

- Shear Modulus: 43 GPa

- Elongation at Break: 54%

- Poisson’s Ratio: 0.34

Thermal Properties

- Thermal Expansion Coefficient (20–100°C): 8.90 μm/m·°C

- Thermal Conductivity: 17 W/m·K

For more information on the properties of titanium grades, our blog also covers Grade 1 Titanium and Grade 2 Titanium.

Titanium Cutting Tools and Equipment

Enterprises involved in titanium cutting should have a deep understanding of different equipment and tools. Choosing the wrong tool can lead to excessive wear, causing time waste during tool changes and higher overall tool costs. Most tools are divided into four categories: cast alloys, high-speed steel (HSS), ceramics, and tungsten carbide.

Can Diamond Cut Titanium?

Diamond is much harder than titanium (98.07 on the Rockwell hardness scale vs. titanium’s 36), making it the hardest element. Diamond-coated discs or blades are used to cut titanium rings.

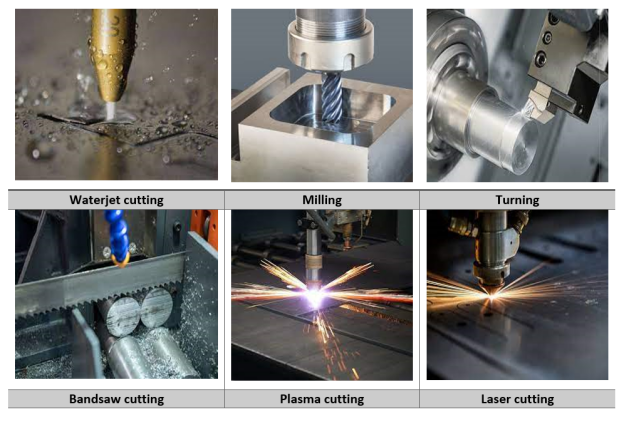

How to Cut Titanium: A Guide to 11 Cutting Methods

1. Manual Cutting of Titanium Sheets

- Process: Cutting titanium sheets is feasible but challenging due to their high hardness. Tools like power hacksaws, band saws, and circular saws can be used. Mark the sample and apply force with the tool.

- Tools: Power hacksaw, band saw, circular saw.

- Advantages: Cost-effective, easy tool access, and precise control.

- Disadvantages: Time-consuming.

2. Saw Cutting Titanium

- Process: Precision sawing of titanium alloys produces clean, smooth edges, critical for aerospace and medical applications.

- Tools: Band saws with carbide-tipped blades.

- Advantages: High speed, minimal heat transfer, and long blade life.

- Note: Requires coolant to improve precision and prevent contamination.

3. Cutting with an Angle Grinder

- Process: Use an angle grinder with a cutting disc. Masonry discs with silicon carbide abrasive are faster than ordinary aluminum oxide discs.

- Tools: Angle grinder, silicon carbide cutting disc.

- Advantages: Relatively fast and accessible.

- Note: Requires patience due to titanium’s hardness.

4. Laser Cutting Titanium

- Process: Uses a CO₂ laser with a combination of nitrogen and oxygen, causing the metal substrate to burn. Professional manufacturers optimize gas mixtures for superior surface finish.

- Tools: CO₂ laser cutter.

- Advantages: High precision, narrow kerf width.

5. Plasma Cutting Titanium

- Process: Plasma torches or CNC plasma machines use a mix of argon (for precision) and nitrogen (for speed) to cut titanium.

- Tools: Plasma cutter, argon, nitrogen.

- Advantages: Fast cutting speed, adaptable to complex shapes.

6. Turning Titanium

- Process: Machining titanium on a lathe requires low speeds to prevent overheating and extend tool life. TiAlN-coated carbide tools via PVD process are effective.

- Tools: Lathe, TiAlN-coated carbide tools.

- Advantages: Suitable for cylindrical parts, high material removal rate.

7. Milling Titanium

- Process: Similar to turning, milling titanium requires low speeds and heat-resistant tools to avoid equipment damage.

- Tools: Milling machine, TiAlN-coated carbide tools.

- Advantages: Versatile for complex geometries.

8. Waterjet Cutting

- Process: Uses high-pressure water jets (with abrasive for titanium) to cut up to 8 inches thick, surpassing laser/plasma in thickness. No heat-affected zone (HAZ).

- Tools: Waterjet cutter, abrasive material.

- Advantages: Cold cutting, suitable for all titanium alloys, no HAZ.

9. CNC Machining

- Process: Computer numerical control (CNC) machines are programmed to cut titanium sheets and plates with precision.

- Tools: CNC machine, specialized cutting tools.

- Advantages: Automated, precise, consistent, and repeatable.

10. Electron Beam Machining (EBM)

- Process: Uses high-speed electron beams to remove material, ideal for hard-to-machine materials like titanium.

- Tools: EBM machine.

- Advantages: Low thermal impact, high precision, suitable for complex designs.

- Disadvantages: Expensive, specialized.

Summary Table of Cutting Methods and Advantages

| Cutting Method | Key Advantages |

|---|---|

| Manual Cutting | Enhanced control, minimal HAZ, reduced material waste |

| Saw Cutting | High speed, minimal heat transfer |

| Laser Cutting | High precision, narrow kerf width |

| Plasma Cutting | Fast cutting, compatible with multiple materials |

| Turning/Milling | Suitable for cylindrical/complex shapes, high material removal rate |

| Waterjet Cutting | Cold process, no HAZ, cuts thick sections |

| CNC Machining | Automated precision, consistency, and repeatability |

| Electron Beam Machining | Low thermal effect, ideal for additive manufacturing and complex designs |

Choose the cutting method based on your specific requirements for precision, material thickness, production scale, and budget. For professional titanium machining solutions, contact Debaolong Seiko for customized quotes and technical support.

The Best Methods for Cutting Titanium Alloys

Titanium alloys are known for their high strength and hardness. The optimal method for cutting titanium is using carbide-tipped band saws. These not only provide precise cuts but also enhance blade longevity and cutting speed. Most applications utilize tungsten carbide or titanium carbide cutting tools.

Can Titanium Rings Be Cut?

Yes, titanium rings can be cut, but special tools are required, such as dental saws, drills, or diamond saws.

Cutting Methods for Titanium Rods

Titanium rods offer excellent mechanical properties for applications requiring strength and durability, necessitating proper cutting tools and techniques. Common methods include:

- Hacksaws

- Abrasive saws

- Band saws

- Plasma cutting

These techniques ensure precise and straight cuts. To maintain titanium’s properties, minimizing heat generation via coolants or lubricants is critical.

Cutting Methods for Titanium Sheets

Titanium sheets can be efficiently cut using laser cutting, waterjet cutting, and shearing. These methods generate minimal heat, avoiding work-hardening and ensuring precision—essential for tight-tolerance environments, such as aerospace and medical applications.

Cutting Methods for Titanium Tubes

Titanium tubes (hollow cylindrical structures for fluid/gas transport) can be cut using:

- Abrasive cutting

- Band sawing

- Tube cutting machines

Tool selection depends on requirements like production speed, quality, and material. Lubricants reduce friction to prevent damage to tubes and blades. Light, uniform pressure ensures seamless surfaces.

Applications of Titanium Cutting

Due to its superior properties, titanium finds wide industrial use. Cutting titanium is vital in:

- Aerospace: For manufacturing precision components (high strength-to-weight ratio).

- Medical: As a first-generation biocompatible implant material (corrosion-resistant, non-toxic).

- Manufacturing: For durable, extreme-condition-resistant industrial parts.

Tips for Successful Titanium Cutting

- Low Cutting Speed: Minimizes heat input, reducing deformation and preserving mechanical properties.

- High Feed Rate: Reduces dwell time, enhancing efficiency and minimizing tool wear.

- Ample Cutting Fluid: Lubricates and cools, extending tool life and preventing overheating.

- Sharp Tools & Timely Replacement: Maintains precision and reduces friction; regular replacement ensures consistent quality.

- Continuous Feed: Prevents heat buildup, protecting tools and workpieces.

Why Choose Debaolong Seiko for Custom Titanium Parts

Debaolong Seiko employs advanced manufacturing techniques for precise and rapid cutting/machining:

- High-Performance Components: ISO 9001:2015 certified, offering material selection, design, and cost-optimized solutions.

- Affordable Pricing: Leverages China’s supply chain for competitive costs.

- Small-Batch Production: Capabilities ranging from single prototypes to mass production.

Contact us at www.debaoloong.com to discover how we can assist with your projects.