Can 3D printers work underwater? Yes, you heard that right.

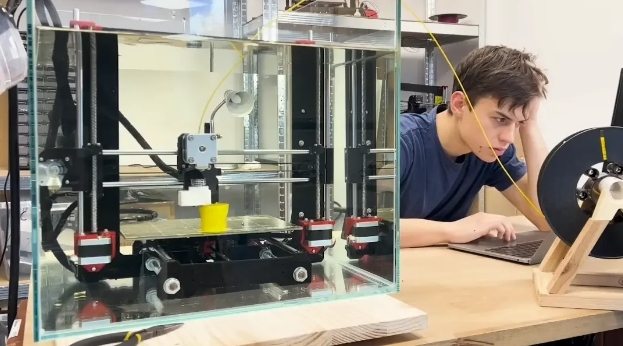

Recently, the YouTube channel CPSdrone posted a video titled Putting my 3D printer underwater, which has garnered over 200,000 views and sparked lively discussions among many fans. At first glance, I wondered if this was just a clickbait title and the print would surely fail. But after watching the entire video, I was amazed to find they actually succeeded—underwater 3D printing is possible.

So how did they achieve this? Weren’t there risks of short circuits, rust, or failed prints?

In fact, they made extensive modifications to ensure the machine operated safely and reliably underwater. Note: The water tank used deionized water, which has extremely low conductivity, for experimental safety.

- Stepper motors: All electrical contacts coated with waterproof epoxy resin.

- Limit switches: Replaced with waterproof equivalents.

- Heated bed: Electrical connections sealed with epoxy resin.

- Motion bearings: Swapped for plastic bearings.

- Display screen: Positioned outside the water tank.

- Frame structure: Metal components replaced with plastic.

- Power supply: Housed in a waterproof box outside the tank.

- Extruder: Cooling fan removed (to avoid water ingress).

- Hot end: Sealed in silicone inside a special “container.”

- Filament spool holder: Mounted above the printer to keep filament dry.

- Circuit board: Encased in an epoxy-sealed waterproof box.

Once everything was ready, the YouTuber began testing.

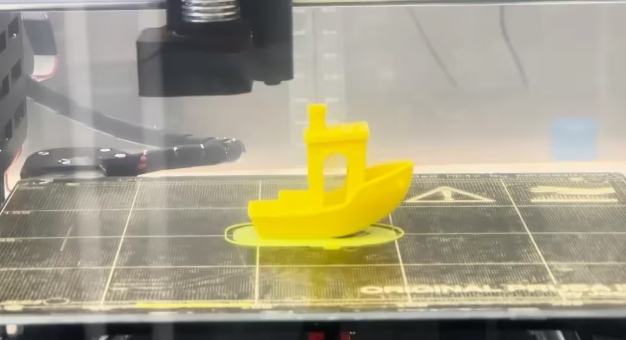

First print attempt: A classic Benchy boat model. Surprisingly, the layers bonded well at first. However, the print failed midway due to a loose power cable. After multiple tries, layer adhesion suddenly failed. They eventually removed the machine from the water and found the silicone seal around the hot end had melted from prolonged heat exposure, allowing water to enter.

After cleaning and refilling the hot end with high-temperature-resistant silicone, they tried again. This time, the Benchy printed successfully, along with a overhang test model and a 23cm bridge test.

Final results: The printed models looked decent visually, but layer adhesion was weak—the Benchy wasn’t structurally strong. This was because the water rapidly cooled each layer, causing the next layer to bond poorly with the cold surface. Overhangs and bridges performed better, likely due to buoyancy reducing sagging in the extruded filament. The hot end’s silicone seal was also replaced with transparent epoxy resin for better results.

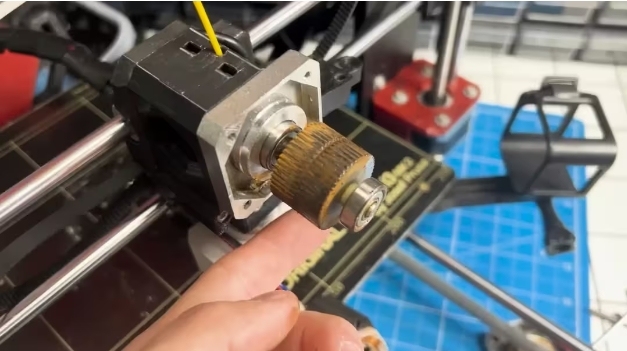

Later, they fully sealed the machine and tested it in a swimming pool, but the attempt was short-lived and unsuccessful due to unspecified issues. After a week of continuous testing, they found:

- The extruder’s drive gears had rusted, making filament feeding impossible.

- The hot end’s sealant couldn’t withstand prolonged heat, leading to water infiltration and heating failures.

Conclusion from the tests: Underwater 3D printing is feasible with modifications, but further improvements are needed, including:

- Using higher-temperature-resistant epoxy for hot end seals.

- Fully waterproofing the extruder motor.

- Heating the water to just below the filament’s glass transition temperature (e.g., below 50°C for PLA) to improve layer adhesion.

Overall, this is an impressive experiment—likely the first of its kind. It proves underwater 3D printing is possible.

The question remains: Will any manufacturers actually develop commercial underwater 3D printers?