When using FDM 3D printers, several common issues often arise. Below, Debaolong Seiko outlines 7 frequent printing problems and their solutions:

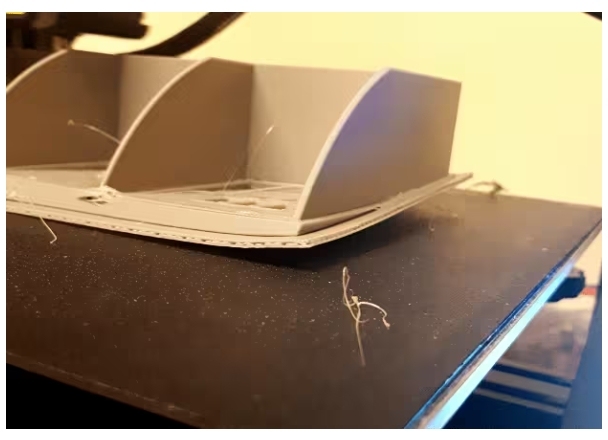

1. Warping

Warping occurs when the printed model curls upward or detaches from the build plate due to material shrinkage.

Solutions:

01. Increase bed temperature: Raise it by 10°C for testing (avoid excessive heat to prevent other issues).

02. Reduce air flow: Minimize drafts in the printing environment; use windshields or insulation covers.

03. Level the bed: Proper bed leveling is critical, especially for large models. Even with auto-leveling, manual adjustment is recommended.

04. Apply glue to the bed: A quick fix, but risks difficult removal and bed damage (not recommended as a primary solution).

05. Use Raft or Brim: These increase contact with the bed and mitigate warping from uneven surfaces.

06. Optimize first layer settings: Increase first layer height by 50% and temperature by 5–10°C.

07. Use high-quality filament: Choose filaments with high purity (e.g., 90%+ PLA) to reduce shrinkage from mixed plastics.

2. First Layer Not Sticking

A poorly adhered first layer makes successful printing impossible.

Solutions:

01. Increase bed temperature: Test a 10°C increase, as with warping.

02. Adjust bed leveling and Z-axis distance: Ensure the nozzle is close enough to slightly flatten the filament for adhesion.

03. Maintain the bed: Keep the bed clean. For glass beds, wait for full cooling before removing models to preserve surface texture. Avoid excessive glue use.

04. Use Raft: Helps compensate for poor nozzle-bed distance.

05. Optimize first layer settings: Same as warping solutions (e.g., increased height/temperature).

06. Apply glue to the bed: Use sparingly due to removal challenges.

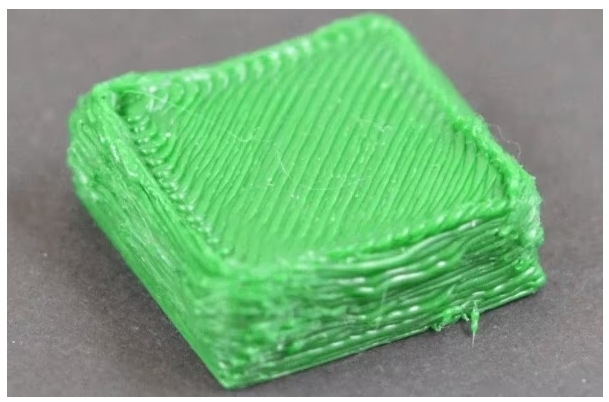

3. Under-Extrusion

Under-extrusion results in rough, fragile prints with gaps.

Solutions:

01. Increase printing temperature: Raise by 5–10°C or perform a temperature tower test to find the optimal setting.

02. Check extruder and gears: Tighten screws and clean gears regularly to remove debris.

03. Clear the nozzle: Use specialized cleaning filaments to unclog the nozzle.

04. Replace the nozzle: Worn nozzles cause inconsistent extrusion; replace them periodically.

05. Calibrate the extruder (e-steps): Adjust extrusion settings for precise material flow (complex process requiring separate guidance).

06. Adjust retraction settings:

- For Bowden (remote) extruders: 5 mm retraction distance, 45 mm/s speed (Cura).

- For direct extruders: ~1 mm retraction distance, ~35 mm/s speed.

4. Over-Extrusion

Excessive material deposition, often easier to resolve than under-extrusion.

Solutions:

01. Lower printing temperature: Cooler filament reduces sagging from overheating.

02. Calibrate extruder steps: Ensure accurate material flow.

03. Replace the nozzle: Worn nozzles with enlarged diameters cause over-extrusion.

04. Adjust belts and rollers: Over-tightened components can delay nozzle movement, leading to excess material.

5. Ghosting/Vibrational Lines

“Ripple” defects on the print surface due to printer vibrations from rapid speed/direction changes.

Solutions:

01. Use a stable platform: Place the printer on a solid, non-shaking surface.

02. Reduce print speed: Slower speeds improve stability.

03. Lighten moving parts: For I3-style printers, reduce the weight of the heated bed to minimize inertia.

04. Lower acceleration/jerk settings: Stick to default values to reduce shaking.

05. Tighten rollers and belts: Loose components cause misalignment and ghosting.

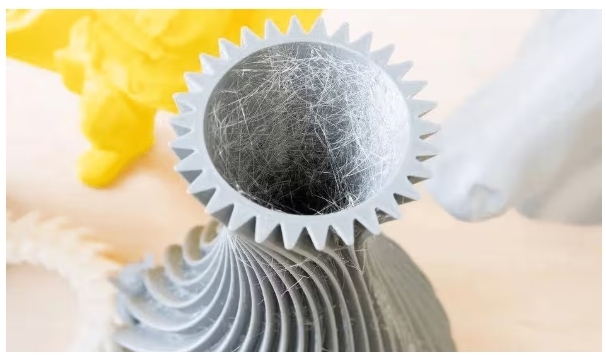

6. Stringing

Thin filament strands between model parts, worsened by humid filament.

Solutions:

01. Enable/increase retraction: Adjust distance and speed (test increments). Increase travel speed during retraction.

02. Lower printing temperature: Use the minimum recommended temperature for the filament or perform a temperature tower test.

03. Dry the filament: Bake at 45–50°C for 4–5 hours in an oven or dehydrator to remove moisture.

04. Clean the nozzle: Clogs or residue can cause stringing; use cleaning filaments.

05. Use pure filament: PLA is less hygroscopic than modified filaments. Pure PLA reduces moisture-related issues.

06. Post-process with a heat gun: Gently remove strings from finished prints.

7. Blobs or Zits on Prints

Unexplained bumps or spots, often hard to diagnose.

Solutions:

01. Lower printing temperature: Excessive heat can cause material to ooze under pressure.

02. Optimize retraction: Balance retraction distance/speed to avoid air bubbles from over-retraction.

03. Adjust extruder path and coasting: Use Cura’s “combing” feature to minimize travel over the model. Enable “coasting” (0.2–0.5 mm) in experimental settings to reduce Z-seam blobs.

04. Improve cooling and dry filament: Enhance part cooling and dry wet filament to reduce bubbling and oozing.