Every assembly task requires fasteners, through-pieces, and through-holes for specific purposes, all achievable by drilling holes of specific sizes in the same assembly. However, to complete a drilling operation, you must select, process, and use the right tools and drill bits—otherwise, defective holes will become the final product, potentially leading to rejection during quality inspection. This article provides a comprehensive guide to the process.

How to Drill Through Metal

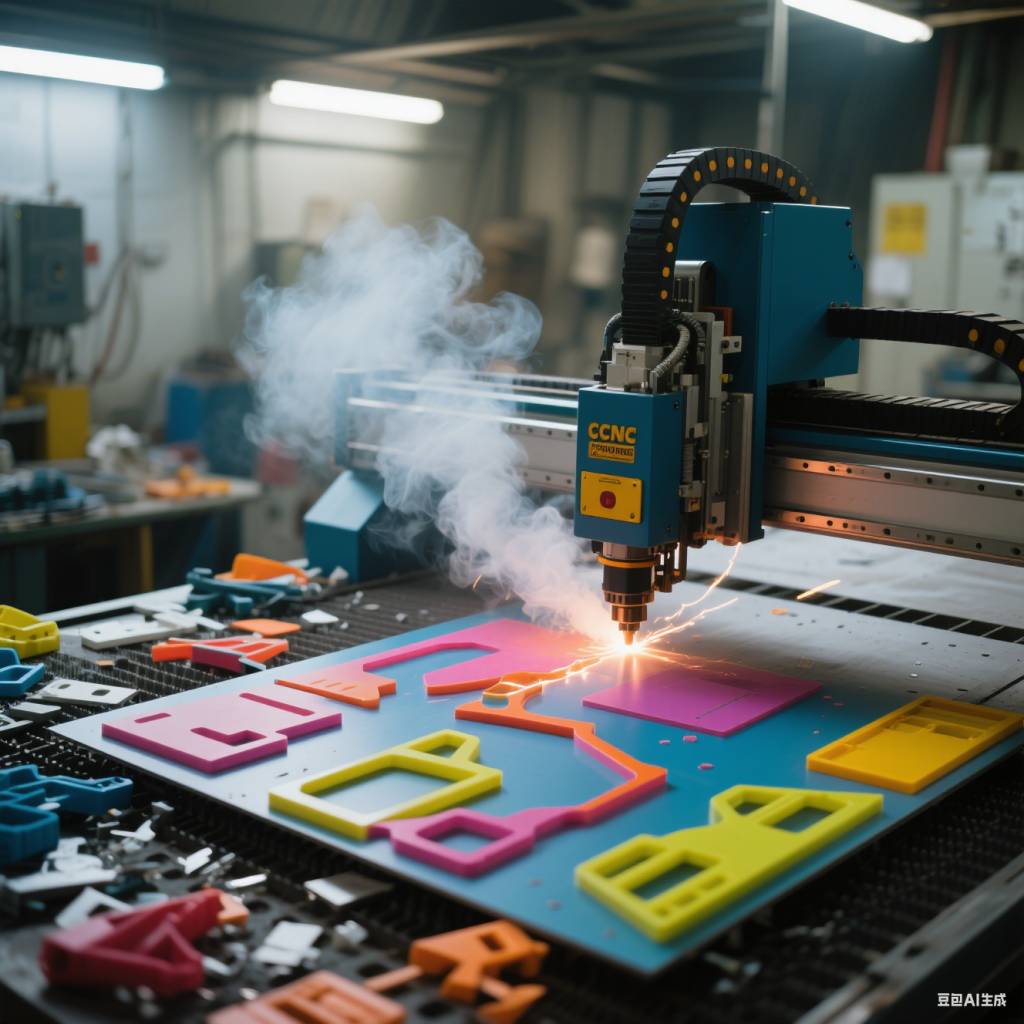

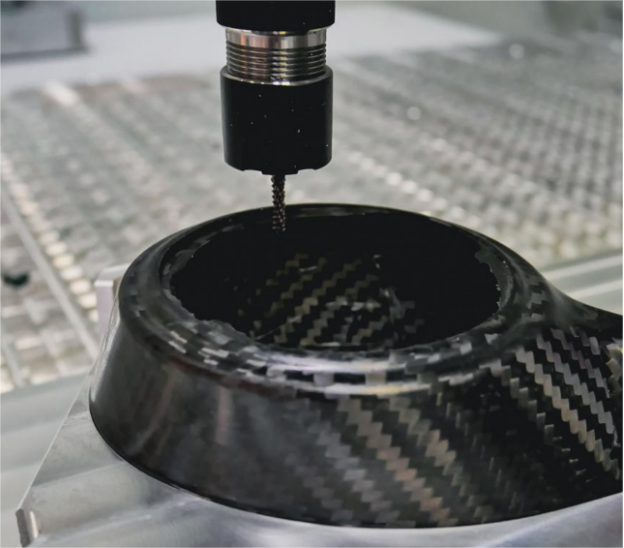

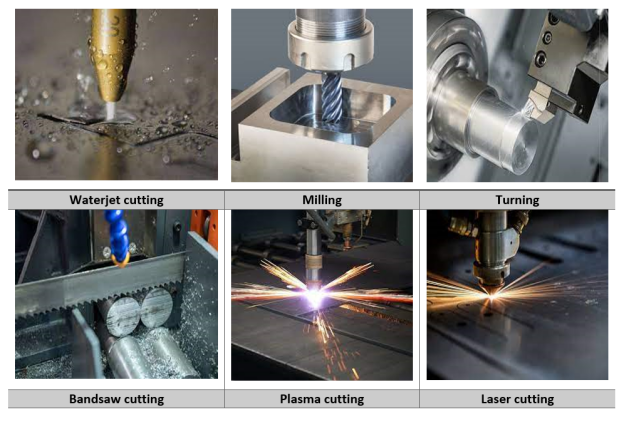

Drilling through metal requires a drill press, drill bits, coolant, tools, clamps, and workpieces to machine holes of the required size without thermal or hammering processes. CNC machines offer the same capability with far higher precision than manual drill presses. CNC drills use a specialized CNC system and mechanized clamping motor system to move the drill bit to linear and angular positions within tight tolerances. The process also depends on material plastic deformation, particularly when drilling hardened steel.

Which Drill Bits Are Suitable for Metal?

Cobalt drill bits are ideal for quenched steel, with a cobalt content of 5% to 6% making them harder than ordinary steel for effective penetration. They generate less heat, reducing plastic deformation and thermal energy consumption for a smooth drilling process. Key requirements for drill bit materials are high hardness and low brittleness, making cobalt bits the best choice for steel.

17 Tips for Drilling Metal

Metal drilling seems simple, but for non-professionals, it’s tricky due to material hardness, heat generation, drill bit selection, cutting speed, and feed rate. Factors like surface preparation, lubrication, bit selection, and post-cleaning are essential for efficient drilling. Here are the tips in order:

1. Clean the Drill Table

Workstation cleanliness is crucial for surface finish, workpiece alignment, and hole centering. Metal debris on the drill press surface can also pose safety hazards by interfering with the bed’s movement.

2. Are Metal Drill Bits Suitable for Steel?

Drill bit materials for metal include cobalt, black oxide, and high-strength steel with tungsten/diamond additions. Cobalt bits are optimal, as they drill metal without excessive heat, surface drift, plastic deformation, or bit damage. Black oxide and high-strength steel bits work for softer materials but may fail with high-yield metals.

3. Wear Safety Equipment

Safety is paramount in metal drilling. Essential gear includes:

- Safety goggles

- Emergency stop buttons

- Safety gloves

- Protective clothing

- First aid kits

- Metal chip shields

These items protect operators from injury, especially as each task carries unique risks.

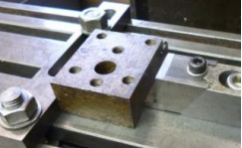

4. Clamp the Metal Part Firmly

Clamping is vital for maintaining:

- Workpiece tolerance

- Vibration control

- Cutting/drilling reference accuracy

- Surface flatness

Inadequate clamping causes deviations from design specs. Modern CNC machines and drill presses use C-clamps and specialized tools to secure workpieces of various profiles.

5. Start with a Pilot Hole

Pilot holes prevent drill bit drift by providing a reference for smooth, linear movement within tolerances. Specific charts and tables guide pilot hole sizes for different materials, dimensions, and profiles.

6. How Big Should a Pilot Hole Be?

The optimal pilot hole diameter is 60%–70% of the final hole size. A too-large hole compromises tolerance, while a too-small hole risks bit damage from lateral movement. Refer to industry standards for precise dimensions.

7. Pilot Hole Size Table

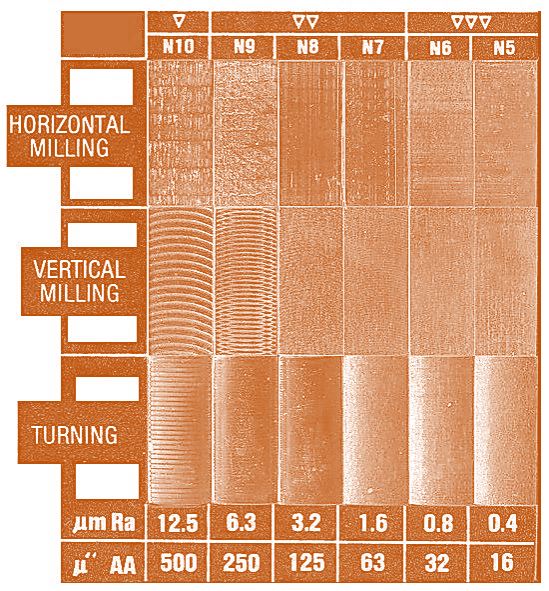

Pilot hole sizes must match drill bits to avoid surface drift, plastic deformation, heat, and tool damage. Table 1 shows recommended sizes:

| Plate Thickness (mm) | Pilot Hole Diameter (mm) |

|---|---|

| 0.57–2.50 | 2.9 |

| 2.51–6.00 | 3.5 |

| 3.51–10.00 | 4.2 |

| 4.76–10.00 | 4.8 |

| 5.00–10.00 | 6.3 |

8. Should You Use Oil When Drilling Metal?

Heat generation during drilling can damage the metal and bit. Using oil or cutting fluid absorbs and dissipates heat. Specialized oils with heat dissipation, low viscosity, and metal compatibility are preferred over organic oils.

9. Go Slow and Steady

Cutting speed and feed rate impact drilling quality by affecting plastic deformation and surface hardening. Fast drilling causes bit drift, while slow drilling generates excessive heat. Balance is key.

10. Pause Regularly to Cool the Drill Bit

Cutting fluid may not fully manage heat from thick or high-strength metal. Regular pauses allow the workpiece to cool naturally and let operators inspect hole quality mid-process.

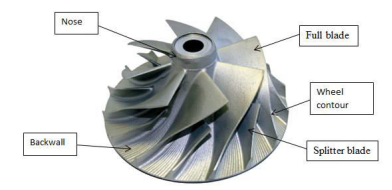

11. Drilling Through Thick Metal: Peck Drilling

Thick metal drilling poses risks from heat, bit drift, and material hardness. Peck drilling—intermittent drilling with pauses—verifies hole progress and ensures smooth operation, minimizing losses from defective parts.

12. Avoid Vibration

Vibration causes workpiece misalignment, affecting hole straightness and assembly. Control vibration through proper clamping, pilot holes, surface finish, and chip removal to maintain hole centering.

13. Mark the Hole

Marking hole positions guides operators and machines, validates CNC drilling against manual references, and calibrates work surface coordinates to reduce post-processing errors.

14. Use a Depth Limiter

Depth control is essential for non-through holes. A depth limiter stops drilling at the desired depth, preventing irreversible over-drilling.

15. Keep the Bit Sharp

Drilling hardened steel requires sharp bits to avoid clogged holes or defects. Bit sharpness checks should be part of standard operating procedures (SOPs), with post-drilling maintenance to preserve bit condition.

16. Make a Sandwich (Bonus Tip)

Using wood as a sandwich layer buffers the workpiece, guiding the drill bit and protecting the metal surface. The wood absorbs initial forces and can be replaced for each drill.

17. Create a Dimple (Bonus Tip)

Dimpling—indenting the surface—guides the drill bit without a pilot hole, offering a cost-effective solution for workpieces where pilot holes are impractical.

How to Drill Metal with a Hand Drill

When a drill press is unavailable, use a hand drill with portable bits, marking tools, a tape measure, and deburring tools. Steps: clean the substrate, mark hole positions, and drill to specifications.

Advantages and Disadvantages of Metal Drilling

| Advantages | Disadvantages |

|---|---|

| Accurate drilling method | Initial capital investment |

| Effective for size tolerance | Requires operator training |

| Cost-effective | Noisy operation |

| Technologically versatile | Inapplicable to all profiles |

| Safer operation | Chips may pose nearby hazards |

Why Choose Debaolong Seiko for Custom Metal Drilling Services

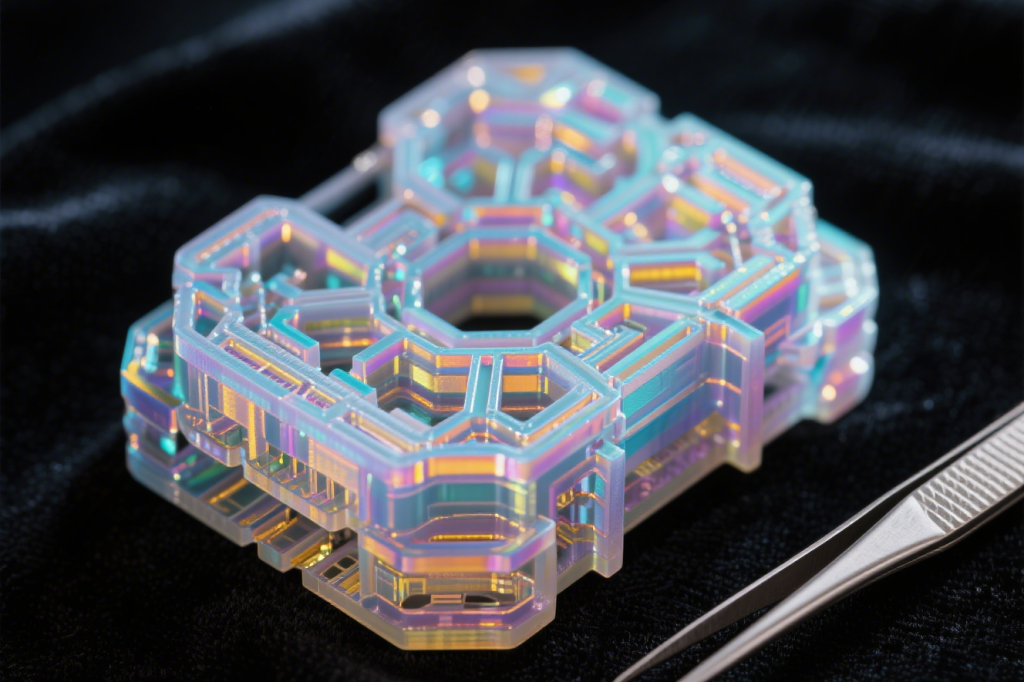

Standard metal drilling is straightforward, but custom parts require certified expertise, training, and machine calibration for dimensional tolerance and quality. Debaolong Seiko offers:

- 24-hour quotes based on engineering drawings

- CNC drilling expertise

- ISO 9001 certification

- High-tech quality control systems

For more information, visit www.debaoloong.com to contact us.