After nearly a decade of development, 3D printing technology in the medical field has transcended traditional uses like orthopedic implants, surgical guides, and rehabilitation aids. It is now driving a new wave of innovation, from creating beating hearts and breathable lungs in research to advancing transplantable organ studies. Recent breakthroughs span oral soft tissues, microneedle patches, artificial corneas, skin grafts, and full-denture prosthetics. This article compiles the latest medical advancements in 3D printing.

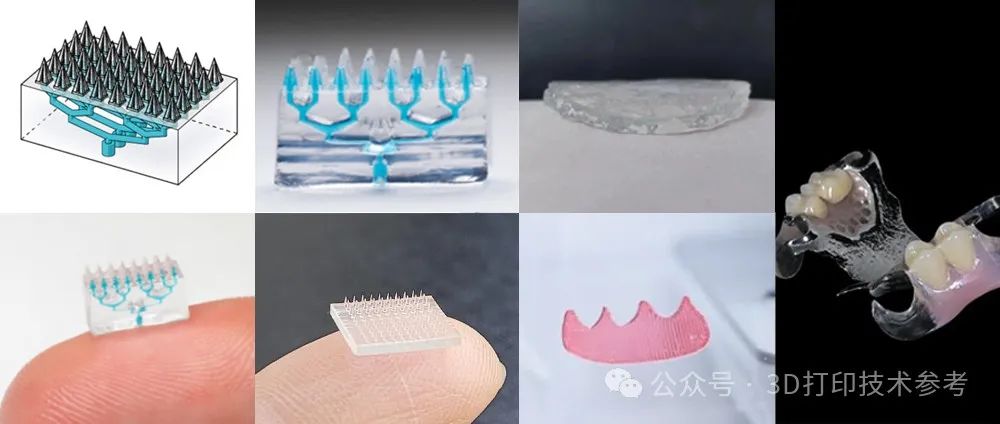

Microneedle Patches: Replacing Injection Needles

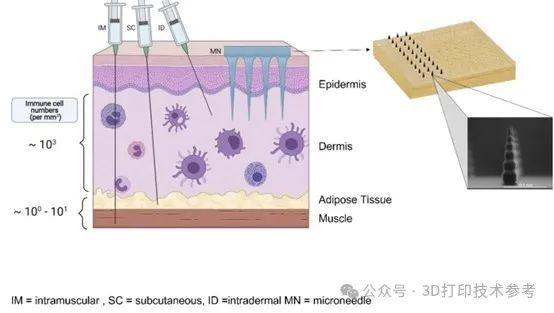

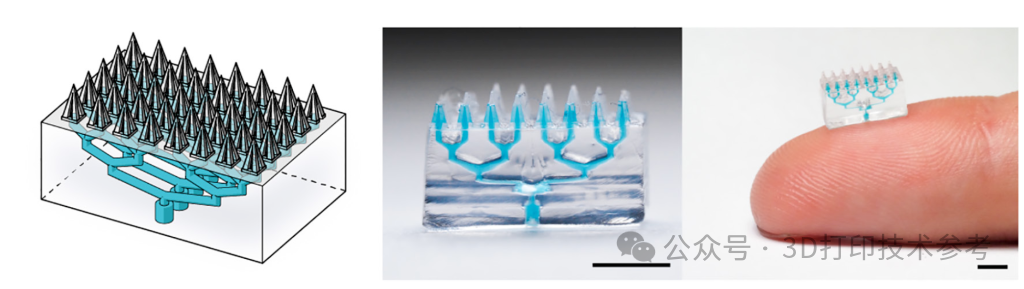

Stanford University professor and Carbon co-founder Dr. Joseph DeSimone has launched PinPrint, a startup developing 3D-printed microneedle patches that deliver drugs and vaccines through the skin—eliminating the need for syringes. This innovation could revolutionize therapy in pharmaceuticals and cosmetics.

Dr. DeSimone’s team overcame the challenge of resin over-curing in tiny spaces using their injection continuous liquid interface production (iCLIP) method, creating ultra-precise microneedles and microfluidic channels vital for advanced medical devices. These patches not only deliver vaccines more effectively but also simplify storage and self-administration. By targeting the dermis—where immune cells concentrate—they enhance vaccine efficacy, reduce reliance on cold-chain logistics, and enable wider distribution.

Beyond drug delivery, PinPrint’s platform holds diagnostic potential. By collecting interstitial fluid, the patches may monitor glucose levels or immune responses non-invasively, heralding a future of “less traumatic, more continuous, and personalized” healthcare. The shift toward painless, sticker-like medications—precisely designed via 3D printing—signals a paradigm change in how drugs and data move within the body.

3D-Printed Cornea Models: Advancing Dry Eye Research

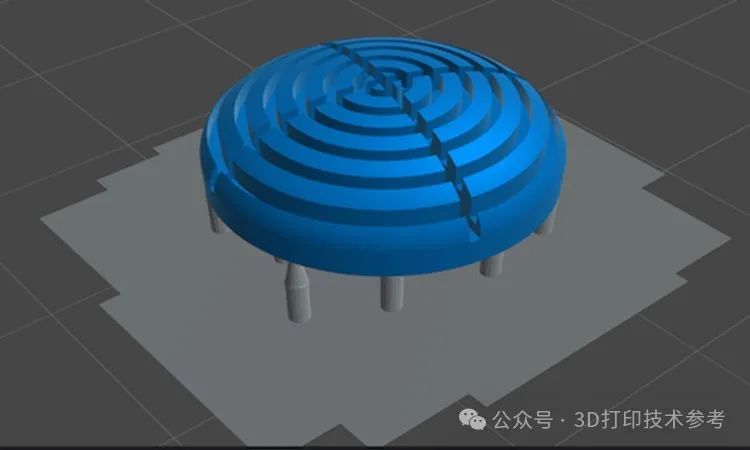

Dr. Yuqiang Bai from the University of South Florida (USF) Morsani College of Medicine, funded by the National Institutes of Health, leads groundbreaking dry eye research. To support this, USF IT’s 3D printing lab, led by Lucas Tometich, designed a tool to test Dr. Bai’s laser scanner for imaging corneal tear thickness.

Affecting millions worldwide, dry eye requires accurate corneal curvature imaging. Traditional flat standards (e.g., 1951 USAF resolution charts) fail to match the cornea’s unique shape. Tometich’s team used Autodesk Fusion to create a 3D-printed model mimicking corneal curvature. “I iterated on designs and post-processing workflows to ensure clarity with transparent photopolymer resin,” Tometich said. “We delivered multiple samples for scanner validation.” Such standardized curved samples enable the team to develop precise imaging systems for dry eye diagnosis.

3D-Bioprinted Oral Soft Tissue Grafts

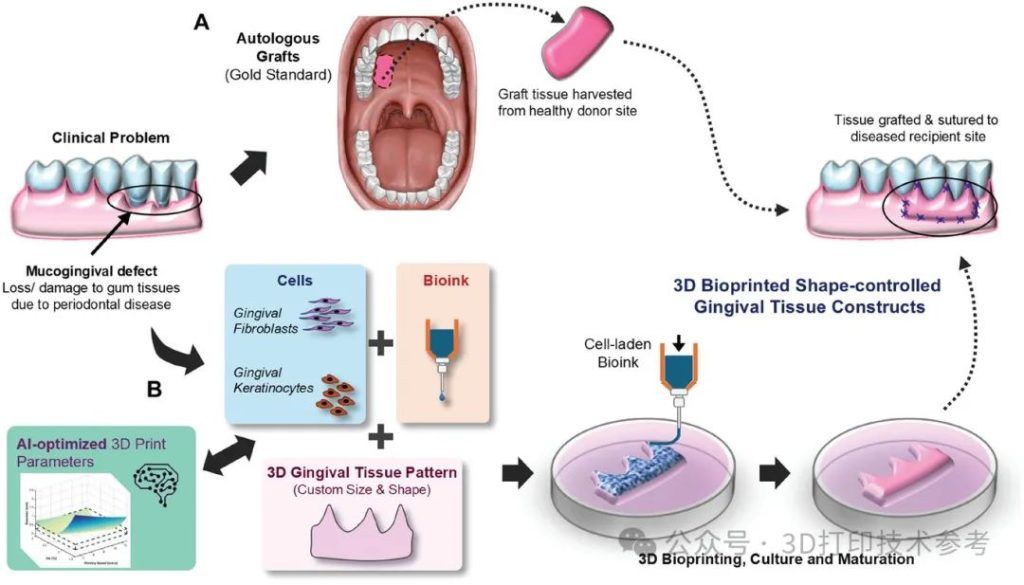

Researchers at the National University of Singapore have combined 3D bioprinting with AI to create personalized gum tissue grafts, addressing critical challenges in dental surgeries for periodontal disease or implant-related defects. Supported by Singapore’s National Additive Manufacturing Innovation Hub and NUS Health System, this technology fabricates anatomically precise grafts, improving treatment outcomes and reducing infection risks.

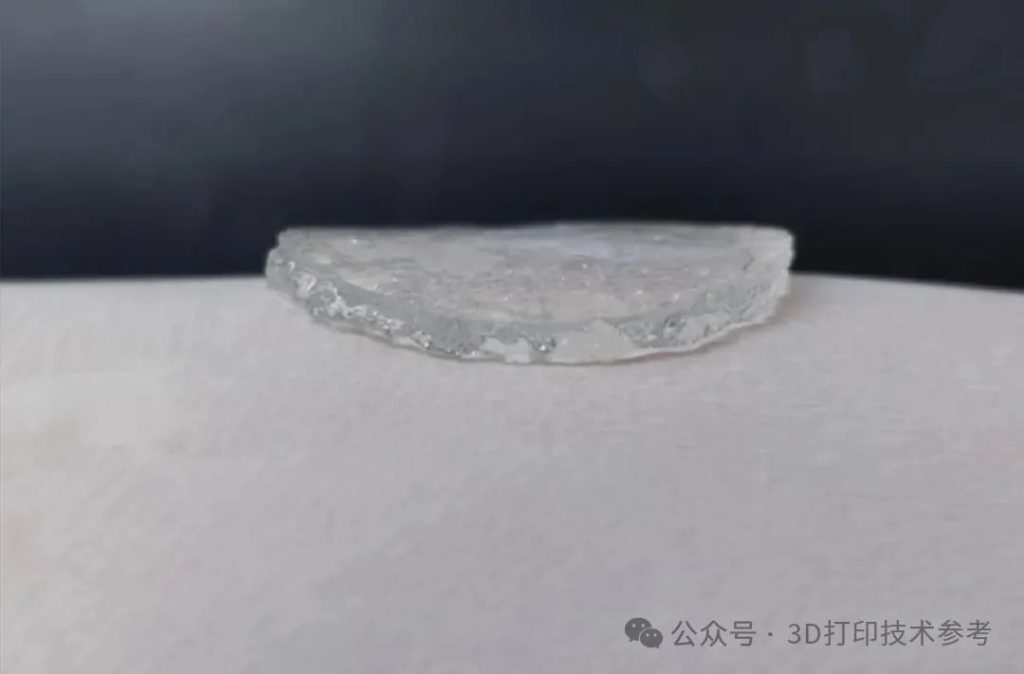

Regenerating oral soft tissue defects requires structures with precise dimensions and layered cellular organization. The study uses AI-driven tools to optimize bioprinting parameters in real time, monitoring and correcting process deviations to enhance consistency. Dean Ho’s team reduced parameter optimization experiments from thousands to just 25 using AI, developing a bioink that maintains 90%+ cell viability post-printing and after 18-day culture. The grafts’ multilayered structure mimics natural gum tissue, minimizing donor tissue harvesting and wound tension.

This research may extend to skin regeneration for scarless healing. Future work will focus on in vivo implantation, host tissue integration, and long-term stability in the oral microenvironment, exploring multi-material bioprinting to incorporate blood vessels.

Ricoh’s Inkjet 3D Printing: Aesthetic and Durable Dentures

Ricoh has developed a material jetting-based 3D inkjet technology that overcomes limitations in strength and color design, producing full-color plastic products with high mechanical strength and biocompatibility. Traditional SLA technologies for dentures or eyewear create monochromatic parts with limited stability, while material jetting lacks functional durability. Ricoh’s UV-cured inks with functional fillers ensure strength and sprayability, using semi-transparent white/clear resins as bases and high-concentration CMY inks for natural tooth color and texture.

Meeting Japan’s JIS T 10993-1 biocompatibility standards, this technology debuted in a Yokohama dental lab to produce long-lasting, aesthetic dentures. Beyond dentistry, Ricoh plans applications in eyewear, combining toughness, color accuracy, and medical safety for personalized healthcare and smart manufacturing.

3D-Printed Functional Skin Tissue: A Breakthrough in China’s Regenerative Medicine

In 2024, CCTV Military reported that the Chinese PLA General Hospital has used 3D-printed artificial skin for combat wound treatment. “Our latest achievement is bioprinting skin with sweat glands, hair follicles, and sebaceous glands—approaching natural skin,” said Academician Fu Xiaobing. “This enables rapid wound healing and combat readiness recovery.”

Bioprinted skin offers speed: after extracting and culturing a patient’s skin cells, printing begins within 1-2 days. The team validated the technology in clinical trials and developed a simplified method for field use. Huangsha said, “We have deployed the simple printing method to the company (corporations) for wound management training.” The results have been promising.

Conclusion

As a key field alongside aerospace, 3D printing in healthcare directly benefits patients by enabling personalized, minimally invasive therapies. Applications like microneedle patches, corneal models, oral grafts, dentures, and skin tissue are reshaping medical workflows—alleviating physical and psychological burdens while maximizing efficacy.

For more information, contact Debaolong Seiko.