Blackened steel has emerged as a popular material choice in modern design and architecture, celebrated for its aesthetically striking and durable surface that enhances the visual appeal of residential and commercial spaces. Whether you’re a manufacturing professional, mechanical designer, or someone looking to integrate blackened steel into projects, this guide offers insights into the material, blackening processes, and best practices for design integration.

What is Blackened Steel?

Blackened steel refers to steel that undergoes chemical or heat treatment to achieve a dark, matte, or glossy surface finish. This process not only enhances aesthetics but also forms a corrosion-resistant layer, making it ideal for functional and decorative applications.

Benefits of Steel Blackening

Steel blackening, also known as black oxide coating, offers several key advantages:

- Corrosion Resistance:

The black oxide layer provides a thin protective barrier against rust, especially when combined with sealants like oil or wax. - Enhanced Aesthetics:

Blackening gives steel a smooth, uniform, and sophisticated appearance, making it a top choice for decorative hardware, tools, or automotive parts. - Reduced Light Glare:

The matte surface of blackened steel minimizes reflection and glare, suitable for applications where light interference is undesirable (e.g., optical instruments or certain weaponry). - Dimensional Stability:

Unlike other coatings, blackening does not significantly alter the steel’s dimensions, making it suitable for precision parts with tight tolerances. - Increased Wear Resistance:

The black oxide layer slightly hardens the surface, reducing abrasion and extending the lifespan of steel components. - Cost-Effectiveness:

Compared to surface treatments like painting or electroplating, blackening is a relatively affordable process to enhance steel performance.

Does Blackened Steel Rust?

Blackened steel is more rust-resistant than untreated steel but not entirely rust-proof. The black oxide layer itself provides some protection by reducing exposure to moisture and air—primary causes of rust. However, without proper maintenance (e.g., regular oiling or waxing), the protective layer can wear over time, leaving steel vulnerable to corrosion.

Key Considerations:

- Indoor vs. Outdoor Use:

Indoor applications typically require minimal maintenance to stay rust-free.

Outdoor use, especially in harsh environments, demands additional protective coatings or frequent upkeep. - Maintenance:

Regular application of protective oil or wax helps preserve the black oxide layer, particularly in high-humidity or saltwater-exposed areas.

Blackening Processes for Steel

The finish of blackened steel varies by method. Common processes include:

- Hot Blackening:

Steel is immersed in tanks of chemicals (including caustic soda and nitrites), followed by an oil bath. - Cold Blackening:

Relies on room-temperature chemical reactions, often using selenium dioxide solutions. - Painted Alternatives:

Some paints mimic black steel’s appearance, offering a less labor-intensive option.

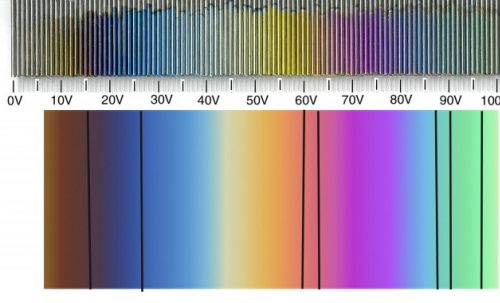

Finish Types: Super Matte, Ultra-Glossy Matte, Neo-Industrial, Extreme Gloss

These terms describe different surface finishes—from completely non-reflective (super matte) to highly reflective (extreme gloss). The choice depends on aesthetic and functional needs.

Preparing Steel for Blackening

Proper preparation ensures a uniform, long-lasting finish:

- Steel Alloy, Scale, and Galvanization:

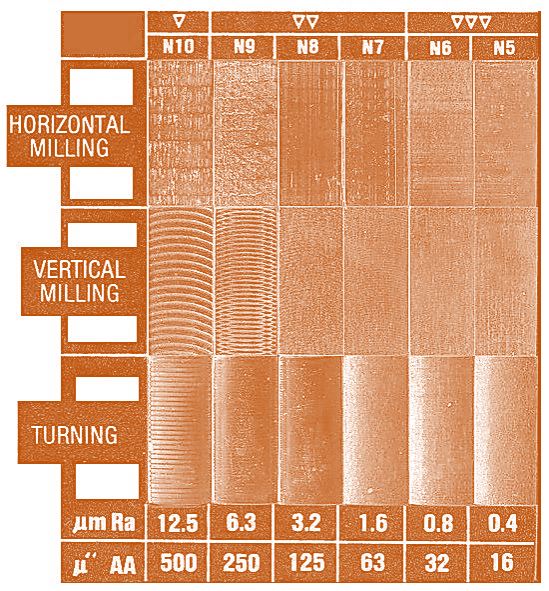

The steel alloy type affects blackening. For example, carbon steel requires thorough cleaning to remove mill scale (iron oxide formed during hot rolling). Galvanized steel, coated with zinc, may need special treatment to remove the zinc layer before blackening. - Mechanical Surface Treatment:

Processes like grinding, sanding, or polishing may be needed to smooth the steel surface. A smoother surface yields a more uniform blackened finish.

Safety Considerations for Steel Blackening

Blackening involves chemicals and high temperatures, requiring strict safety measures:

- Protective Gear:

Always wear gloves, goggles, and long sleeves to prevent chemical contact and burns from hot liquids. - Ventilation:

Ensure proper airflow when using chemicals (especially in cold blackening) to avoid inhaling harmful fumes. - Fire Safety:

Since hot blackening uses flammable liquids like oil, have fire safety equipment (e.g., chemical fire extinguishers) on hand.

Advantages and Disadvantages of Blackening Methods

Choosing between hot and cold blackening depends on cost, desired finish, and application:

| Method | Advantages | Disadvantages |

|---|---|---|

| Hot Blackening | Durable, corrosion-resistant surface Suitable for mass production | Involves hazardous chemicals Requires specialized equipment |

| Cold Blackening | Simpler process No heating needed Operates at room temperature | Less durable than hot blackening Reduced corrosion resistance |

Alternatives to Blackened Steel (Simpler & More Affordable)

For those seeking easier or cheaper options to mimic black steel:

- Painted Products:

Paints and coatings that replicate black steel’s appearance work well for projects not exposed to harsh conditions. - Patina and Chemical Conversion Coatings:

Patina treatments create a weathered look, while chemical conversion coatings form a protective layer, both offering blackened aesthetics without extensive processing.

Why Use Blackened Steel in Design?

Blackened steel stands out for its:

- Aesthetic Appeal:

Its sleek, industrial look contrasts beautifully with light materials, adding depth to modern and traditional spaces. - Durability:

Properly treated blackened steel resists corrosion, suitable for indoor and outdoor use. - Versatility:

It applies to furniture, fixtures, architectural elements (e.g., railings, panels), adapting to diverse design styles.

Sample Specifications: Indoor Blackened Steel Panels

When specifying blackened steel for interior panels:

- Steel Grade: Choose indoor-suited grades like A36 or A500.

- Finish: Specify the desired look (super matte, ultra-glossy, neo-industrial).

- Installation: Use corrosion-resistant fasteners to prevent rust.

Sample Specifications: Blackened Steel Railing Components

For railing applications:

- Steel Grade: Opt for robust alloys like A572 to meet structural requirements.

- Finish: Select durable treatments (e.g., hot blackening) to withstand wear.

- Maintenance: Outline procedures (e.g., regular oiling) to preserve the finish.

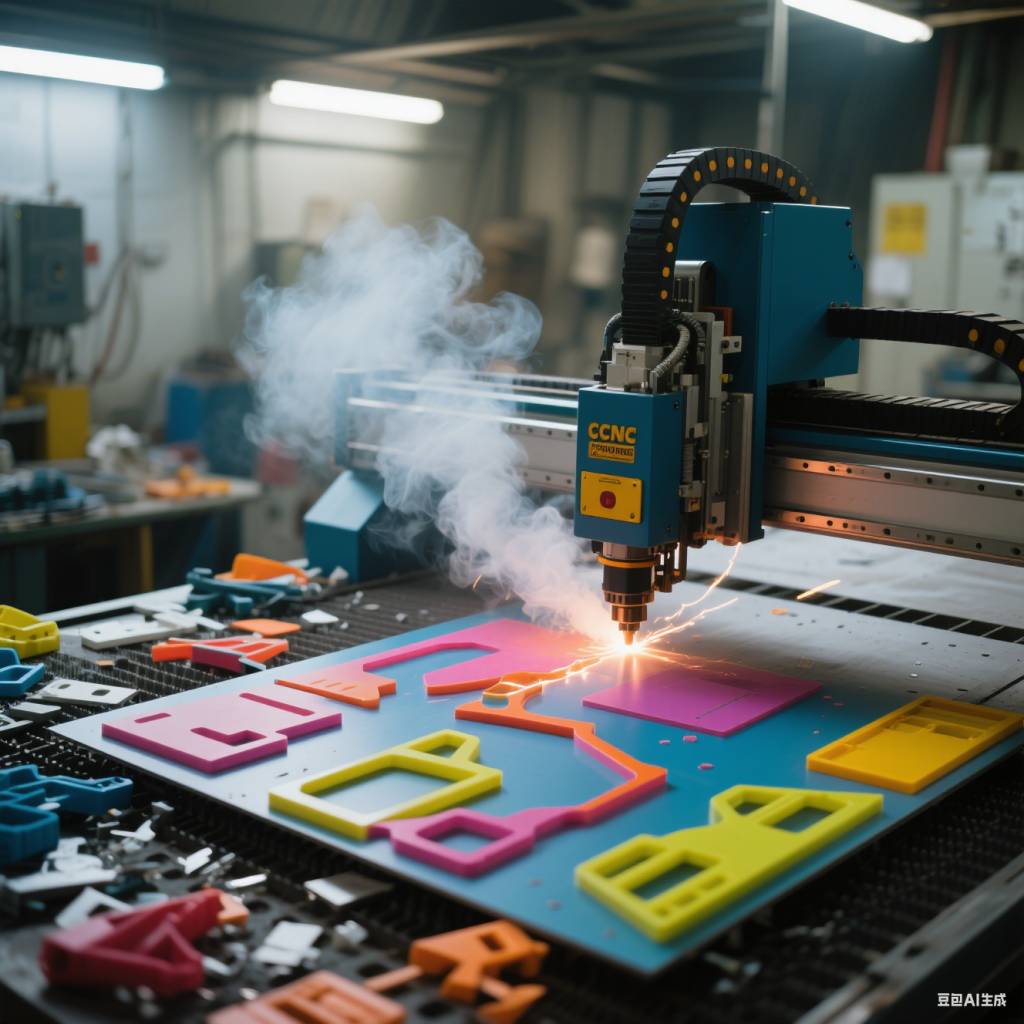

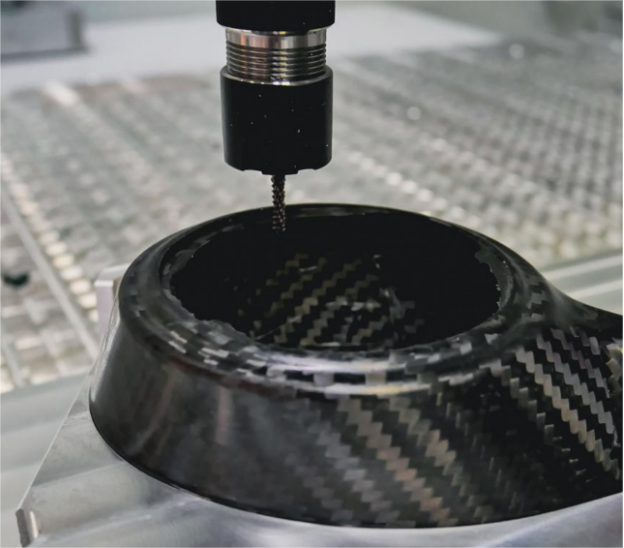

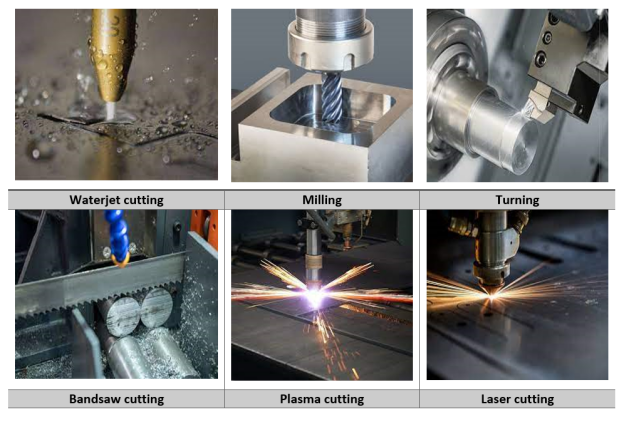

CNC Machined Blackened Steel Parts

Combining CNC machining with black oxide finishing delivers precision, durability, and aesthetics:

| Aspect | CNC Machining | Blackened Steel | Combined Advantages |

|---|---|---|---|

| Precision | Ensures high accuracy and tight tolerances. | Does not alter part dimensions. | Precise parts with uniform black finish. |

| Durability | Reduces wear through precise fitting. | Adds a protective, wear-resistant layer. | Extended lifespan and minimal maintenance. |

| Corrosion Resistance | Machined parts fit perfectly in assemblies. | Provides a rust-proof barrier. | Rust-resistant components for harsh environments. |

| Aesthetics | Enables complex, custom designs. | Offers a uniform matte black finish. | Stylish, professional look for functional/decorative parts. |

| Cost-Effectiveness | Minimizes material waste and production time. | A low-cost finishing process. | High-quality parts at reduced overall cost. |

Applications of CNC Machined Blackened Steel

| Industry | Applications |

|---|---|

| Automotive | Engine components, brackets, fasteners |

| Aerospace | Precision parts requiring high durability and corrosion resistance |

| Tooling | Durable tools and fixtures with wear-resistant surfaces |

For reliable, precise CNC machining with black oxide finishing, trust Debaolong Seiko to deliver excellence in every component.

Conclusion

Blackened steel is a versatile and visually striking material, offering functional and decorative benefits. Whether blackening steel in-house or purchasing pre-treated products, understanding methods and finishes helps optimize project outcomes. Prioritize safety when handling chemicals and heat, and consider alternatives if traditional blackening seems complex or costly.

With this guide, you can integrate blackened steel into designs, ensuring a high-quality finish that enhances both aesthetics and durability.

For more information, contact Debaolong Seiko.