According to the National Institute of Standards and Technology (NIST), researchers have identified a special atomic structure called quasicrystals in 3D-printed aluminum alloys. When material research engineers observed a small piece of the new aluminum alloy under an electron microscope, they noticed atoms arranged in an unexpected pattern. Subsequent analysis confirmed the presence of quasicrystals and revealed that they can enhance the strength of the aluminum alloy.

This study, titled “Microstructural features and metastable phase formation in a high-strength aluminum alloy fabricated using additive manufacturing”, was published in the Journal of Alloys and Compounds. The discovery may facilitate the development of new aluminum alloys that specifically leverage quasicrystals to improve strength. One of the corresponding authors of the study is Fan Zhang.

Quasicrystals: Key to Strength Enhancement

Understanding aluminum at the atomic scale paves the way for new 3D-printed components, such as aircraft parts, heat exchangers, and automobile chassis. It also opens doors to researching new aluminum alloys that use quasicrystals to boost strength.

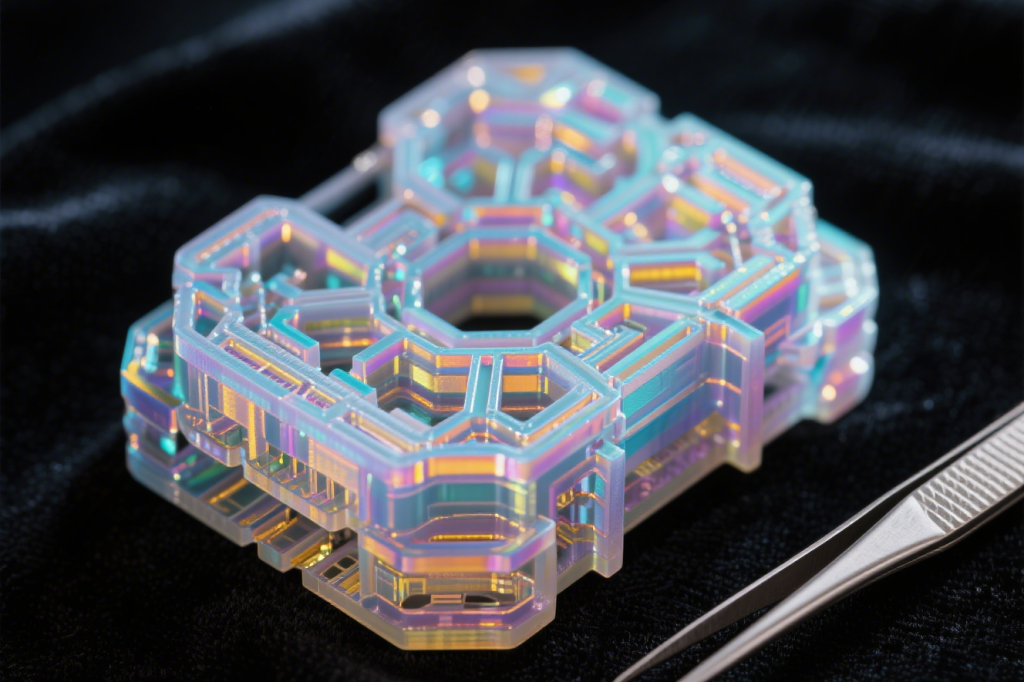

Quasicrystals share similarities with ordinary crystals but have critical differences. Traditional crystals are solids where atoms or molecules form repeating patterns—for example, table salt, whose atoms link to form cubes that stack into larger, visible structures.

This tile pattern exhibits the same properties as quasicrystals: composed of a few identical basic shapes, but the overall pattern never repeats.

While there are only 230 possible ways for atoms to form repeating crystal patterns, quasicrystals belong to none of them. Their unique shapes allow them to create non-repeating patterns that fill space. Dan Shechtman, a materials scientist at the Israel Institute of Technology, discovered quasicrystals during a sabbatical at NIST in the 1980s. At the time, many scientists doubted his research, as the new crystal shape he found seemed impossible under traditional crystallographic rules. However, his meticulous studies proved the existence of this new crystal type, revolutionizing crystallography and earning him the 2011 Nobel Prize in Chemistry. Now, NIST scientists have rediscovered quasicrystals in 3D-printed aluminum alloys.

The Challenge of 3D-Printing Aluminum Alloys

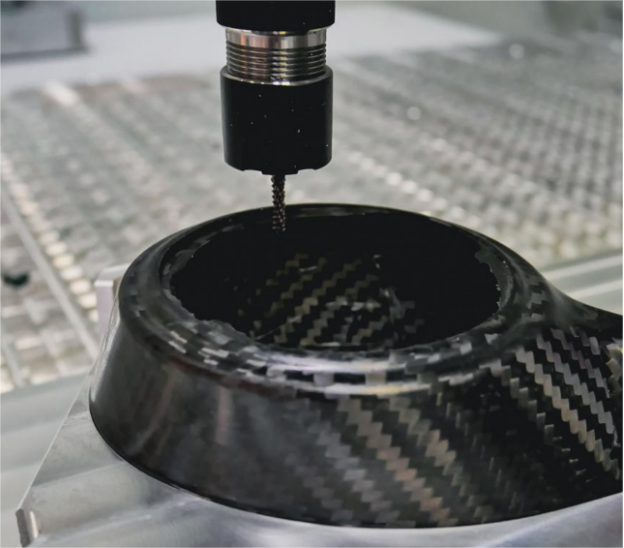

Zhang Fan noted that laser metal 3D printing of aluminum alloys is highly challenging, prone to cracking. Pure aluminum melts at about 700°C, but the laser in a 3D printer must raise the temperature far higher—even exceeding the boiling point of 2,470°C. This process alters many metal properties. Aluminum’s higher thermal conductivity compared to other metals causes it to cool faster, exacerbating these effects.

In 2017, researchers from HRL Laboratories and the University of California, Santa Barbara, developed a zirconium-reinforced aluminum alloy, 7A77. Using zirconium-based nanoparticles as nucleating agents, this alloy avoids the cracking issues of 7075 and 6061 aluminum alloys during laser printing, achieving a fine-grained microstructure with a strength exceeding 600 MPa. NIST studied this aluminum-zirconium alloy to understand its atomic structure. “To ensure this new metal can be used in critical components like military aircraft, we need to deeply understand the interactions between atoms,” Zhang Fan said. They found that quasicrystals play a key role.

Microstructural Insights: Bimodal Structure and Quasicrystals

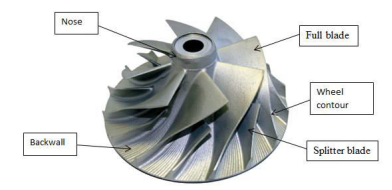

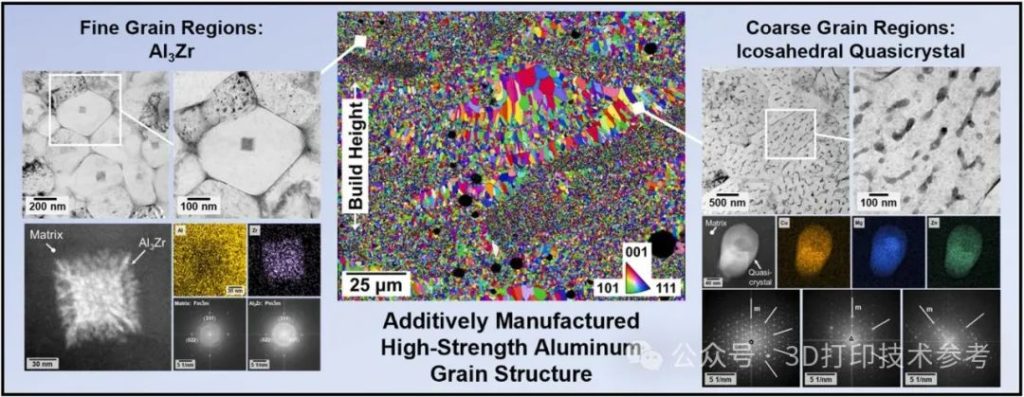

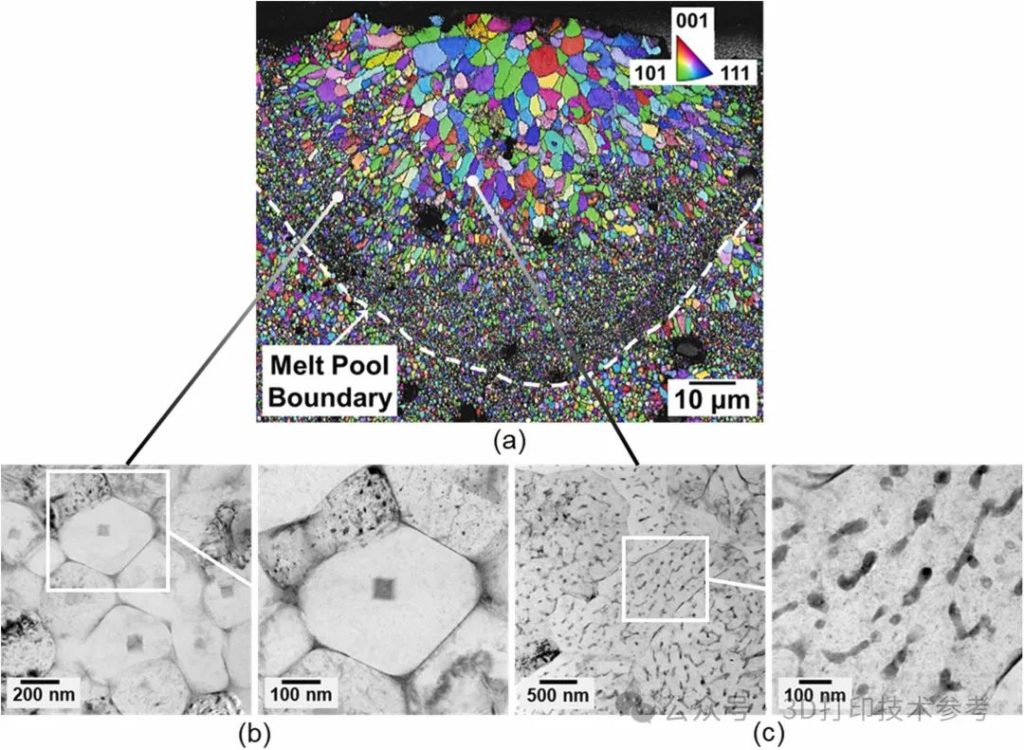

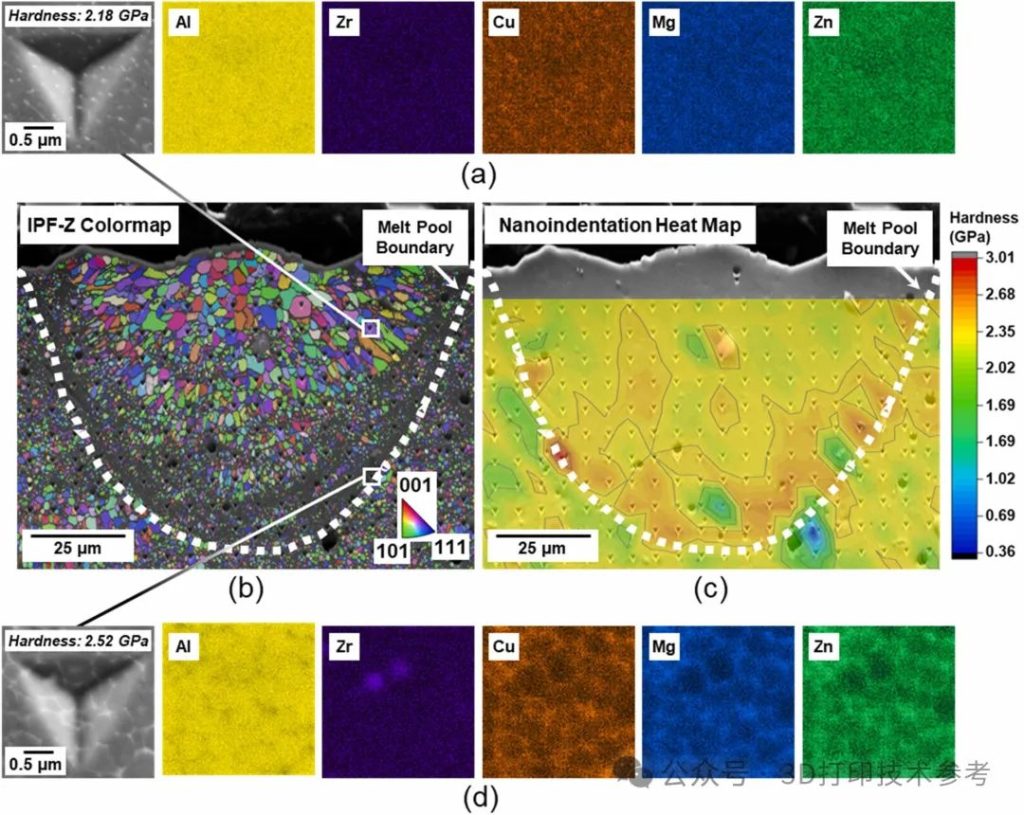

NIST researchers investigated the as-printed microstructure of 7A77 aluminum alloy across multiple length scales. Analysis showed that laser 3D printing introduced various metastable phases into its microstructure. Specifically, they identified a distinct bimodal microstructure in the 3D-printed 7A77: fine equiaxed grains containing Al₃Zr phases and coarser grains with icosahedral quasicrystalline characteristics—previously unreported in such alloys. The fine equiaxed grains distribute near the melt pool boundaries, while the melt pool center features coarser, elongated grains.

Shows fine grains at melt pool boundaries and coarser grains at the center.

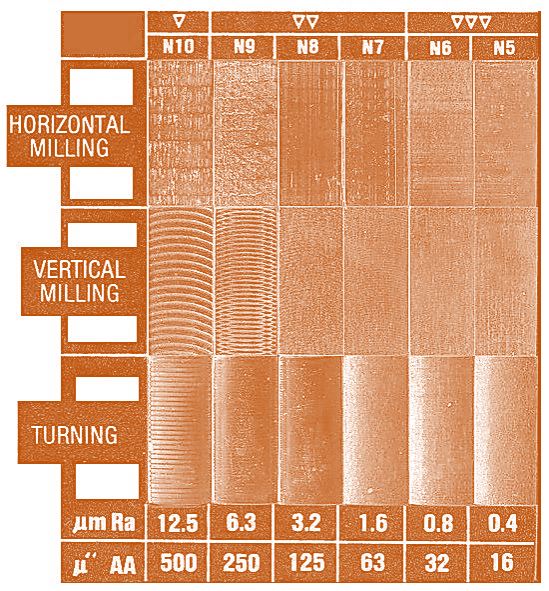

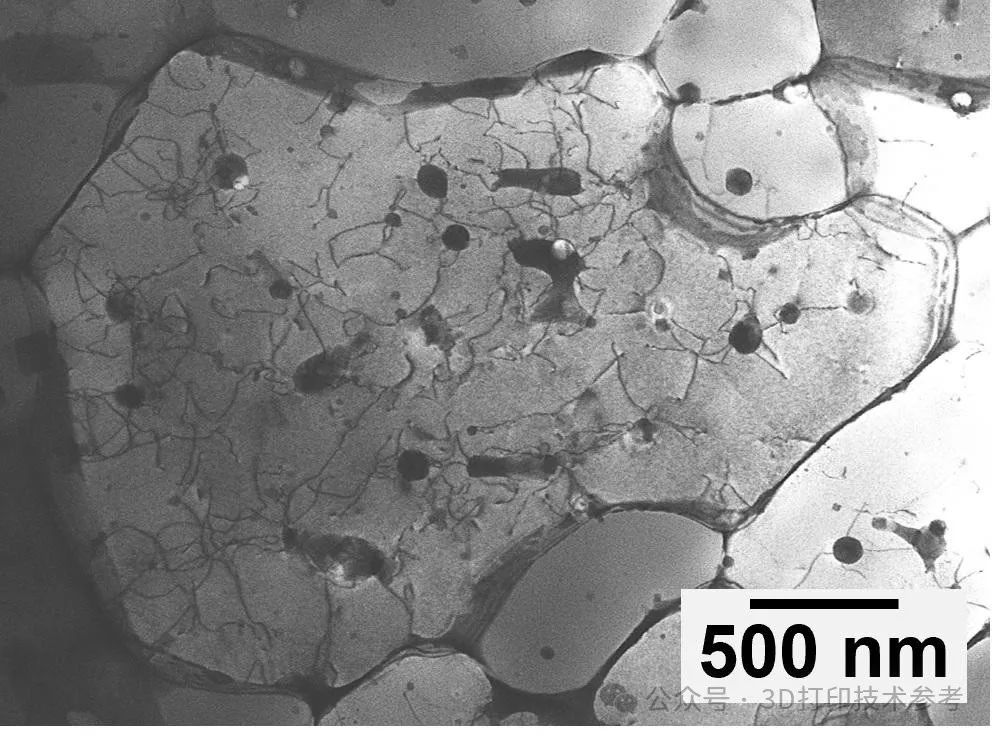

Micrographs reveal light gray regions as cross-sections of traditional crystals in the aluminum alloy, with black dots representing cross-sections of quasicrystals discovered by NIST. Black lines extending from quasicrystal cross-sections are defects that disrupt the traditional crystal pattern, enhancing the alloy’s strength.

Mechanisms of Strength Enhancement

The study indicates that quasicrystal formation occurs late in the solidification process, distributing in interdendritic regions and grain boundaries. Their presence strengthens grain boundaries and hinders dislocation movement, contributing to higher material strength. Test results show the 7A77 aluminum alloy achieves a hardness level comparable to peak-aged 7075, reaching 2.34 GPa. Thus, its mechanical properties can be further improved through subsequent precipitation hardening heat treatment.

(a)(d) SEM images and EDS maps showing indentation in fine-grained and coarse-grained regions.

In metals, perfect crystals are less strong because their regular structure allows atoms to slip past each other easily, causing bending, stretching, or fracture. Quasicrystals disrupt the regular structure of aluminum crystals, introducing defects that make the metal stronger. Overall, this research opens a new pathway for alloy design, harnessing quasicrystals to engineer advanced materials.

Key Terms and Notes:

- Quasicrystals: Non-repeating atomic structures with unique symmetry.

- Metastable phases: Temporary phases that transform over time but stabilize material properties.

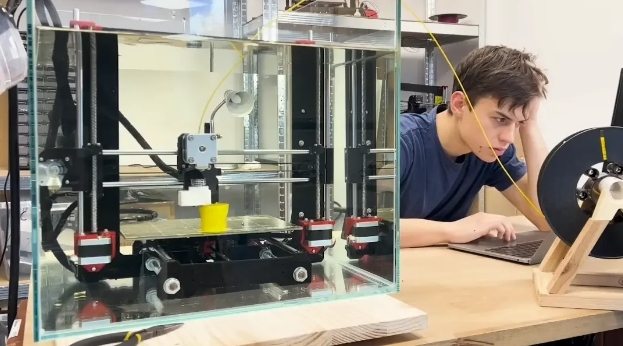

- Additive manufacturing: 3D printing technology using layer-by-layer material deposition.