Anodizing is a renowned electrochemical technique to color metals and alloys. Titanium anodizing differs from aluminum anodizing as it doesn’t use dyes; instead, color changes arise from the material’s reaction with oxygen via an electrochemical process. The oxide layer thickness determines the color. Popular in medical, aerospace, automotive, and jewelry sectors, its low cost and biocompatibility drive widespread use. In automotive parts, it reduces friction, offers corrosion resistance, and increases hardness, making it an ideal passivation technology. This article explores various aspects of titanium anodizing to deepen understanding.

What Is Anodized Titanium?

Anodized titanium involves manipulating the surface properties of base titanium. The metal attaches to the positive terminal (anode) of a cell. As current passes through the cell, oxidation occurs at the anode, forming a passivation layer via electrolysis. The varying oxide layer thickness creates different colors. ASM 2488 is the aerospace industry standard for titanium anodizing.

Can Titanium Be Anodized?

Yes, titanium can be anodized for diverse industries. The process differs from aluminum anodizing in steps. While home-based anodizing is risky due to electricity and chemicals, it’s straightforward and safe at lab or industrial scales.

Titanium Anodizing Process

The titanium anode immerses in an electrolyte (typically sulfuric/phosphoric acid or salt). When the cell activates, electrolysis splits water into hydrogen and oxygen. The potential difference forces oxygen to react with titanium, forming a passive oxide layer.

Type 1 (Transparent/Undyed) Anodized Titanium

This simple process forms a thin layer (0.5–2.5 microns) by cleaning the titanium, immersing it in electrolyte, applying low voltage, and processing for a short time. Used for decoration (commercial anodizing), it improves corrosion resistance with a dark silver or gray appearance.

Type 2 (Wear-Resistant) Anodized Titanium

Thicker than Type 1, Type 2 offers better corrosion resistance, wearability, and hardness with a 5nm titanium dioxide layer. Its gray color distinguishes it from steel, suitable for applications with mechanical stress and friction.

Type 3 (Colored) Anodized Titanium

Type 3 forms the thickest, densest oxide layer, enabling vibrant colors by controlling layer thickness with sulfuric acid as the electrolyte.

Differences Between Type 1, 2, and 3 Titanium Anodizing

| No. | Aspect | Type 1 | Type 2 | Type 3 |

|---|---|---|---|---|

| 1 | Thickness | Low | High | Highest |

| 2 | Thickness Range | 0.5–2.5 microns | 2.5–25 microns | 25–100 microns |

| 3 | Corrosion Resistance | Good | Better | Best |

| 4 | Hardness | Low | High | Highest |

| 5 | Wear Resistance | Low | High | Highest |

| 6 | Color Intensity | Dull | Dull | Vibrant |

| 7 | Color | Dark silver | Gray | Green, blue, purple, gold |

| 8 | Purpose | Commercial | Functional + aesthetic | Aesthetic + functional |

| 9 | Uniformity | Less | More | Balanced |

| 10 | Commercial Name | Chromic acid anodizing | Sulfuric acid anodizing | Hard anodizing |

| 11 | Applications | Enhances paint adhesion | Improves corrosion/wear resistance | Enhances corrosion/wear resistance and mechanical properties |

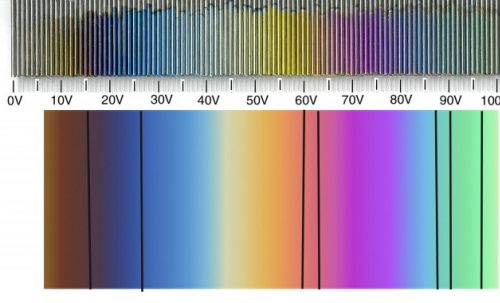

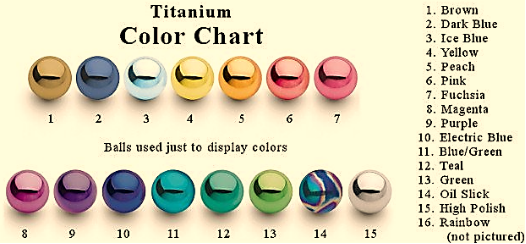

Titanium Anodizing Color Chart

Achieving desired colors and repeatability depends on factors like voltage, titanium purity, and electrolyte composition. The oxide layer thickness influences color through light interference: light reflects off the layer and the metal-oxide interface, creating constructive/destructive interference.

| Thickness | Color |

|---|---|

| ~100 nm | Dark blue |

| ~900–950 nm | Bronze |

| ~800–850 nm | Green |

| ~700–750 nm | Deep blue |

| ~600–650 nm | Purple |

| ~500–550 nm | Turquoise |

| ~400–450 nm | Light blue |

| ~300–350 nm | Yellow/gold |

Titanium Anodizing Patterns

Advanced control over voltage and masking enables patterns like:

- Splatter patterns

- Stripes/bands

- Gradient patterns

- Two-tone patterns

- Polished

- Brushed

- Textured

- Masked designs

- Etched patterns

How to Anodize Titanium

- Cleaning: Remove dust, oil, or grease with alkaline cleaning and water-based resin treatment to prevent uneven anodizing.

- Anodizing Setup:

- Use a plastic container lined with aluminum foil.

- Choose electrolytes based on desired thickness:

- Chromic acid: For thin layers (0.1–0.3 mil) in Type 1/2.

- Sulfuric acid: For thick layers (0.1–1 mil); concentrated sulfuric acid forms non-conductive hard coatings (1–5 mil).

- Phosphoric acid: For thin layers (0.1–0.2 mil).

- Connect titanium to the anode and aluminum foil to the cathode.

- Power Supply: Apply DC current to hydrolyze the electrolyte, forming oxygen that reacts with titanium to build the oxide layer.

- Coloring: Vary voltage to control color: higher voltages yield gold/pink, lower voltages yield blue/purple.

- Rinsing & Sealing: Flush with water to remove residues, then seal pores in hot water for better corrosion resistance.

- Post-Treatment: Polish, brush, or texture the surface as needed.

Inspection of Anodized Titanium

Check the oxide layer for uniformity, thickness, and defects after anodizing.

Specialized Anodizing Techniques

- Splatter Anodizing: Uneven electrolyte application creates artistic patterns via selective oxidation.

- Thermal Anodizing: Heating with a flame or hot air gun changes oxide layer thickness and color.

Black Anodized Titanium

Requires a thick oxide layer to absorb light, forming black. Seal pores once the desired color is achieved.

Blue Anodized Titanium

Controlled anodizing at 700–750 nm or 400–450 nm thickness produces blue via precise layer thickness management.

Hard Anodizing vs. Standard Anodizing

Hard anodizing offers thicker layers, enhancing corrosion resistance, wearability, and hardness compared to standard anodizing.

Applications of Anodized Titanium

- Cookware: Non-stick, corrosion-resistant, and durable titanium cookware with even heat distribution.

- Jewelry: Lightweight, hypoallergenic, and corrosion-resistant rings, bracelets, and necklaces.

- Knives: Corrosion-resistant blades with textured handles for grip, suitable for kitchen use.

- Valves & Exhausts: Titanium valves and exhausts offer low maintenance, heat resistance, and durability.

Mastering Titanium Anodizing Skills

- Understand proper surface cleaning and its impact on results.

- Know titanium alloy compositions and their effects.

- Grasp electrolysis reactions and electrolyte selection for desired colors.

- Familiarize with setup (plastic tanks, masks) and pore-sealing techniques.

Advantages and Disadvantages

- Advantages: Improved corrosion resistance, durability, wearability, hardness, biocompatibility, and aesthetic colors.

- Disadvantages: Complex process, potential oxide layer chipping on hard materials, uniform thickness challenges, and color depth inconsistencies.

Why Choose Debaolong Seiko for Custom Anodized Titanium Parts

Debaolong Seiko provides comprehensive facilities, high-quality equipment, material versatility, and expert advice to meet customer requirements precisely.