1. Workpiece Overcut

Causes:

- Tool deflection due to insufficient strength, excessive length, or small size.

- Improper operation by the operator.

- Uneven cutting allowance (e.g., 0.5mm on curved sides and 0.15mm on the bottom).

- Inappropriate cutting parameters (e.g., too large tolerance, excessive SF setting).

Solutions:

- Tool selection principle: Use the largest possible tool with the shortest feasible length.

- Add corner clearing programs and maintain uniform allowances (keep side and bottom allowances consistent).

- Adjust cutting parameters reasonably, and round off corners with large allowances.

- Use the machine’s SF function for operators to fine-tune speeds for optimal cutting performance.

2. Centering Issues

Causes:

- Inaccurate manual operation by the operator.

- Burrs on the mold perimeter.

- Magnetism on the centering rod.

- Non-perpendicular mold edges.

Solutions:

- Double-check manual operations; center at the same point and height repeatedly.

- Remove burrs with an oilstone or file, wipe clean with a rag, and confirm by hand.

- Demagnetize the centering rod before use (consider ceramic centering rods).

- Check mold perpendicularity with a dial indicator; consult fitters for solutions if errors are significant.

3. Tool Setting Issues

Causes:

- Inaccurate manual operation by the operator.

- Improper tool clamping.

- Errors in fly cutter blade installation (fly cutters inherently have minor errors).

- Tolerances between R-end mills, flat-end mills, and fly cutters.

Solutions:

- Double-check manual operations; set tools at the same point repeatedly.

- Clean the tool shank with an air gun or rag before clamping.

- Measure the fly cutter arbor when installing blades; use a single blade for surface finishing.

- Create a separate tool setting program to avoid errors between R-end, flat-end, and fly cutters.

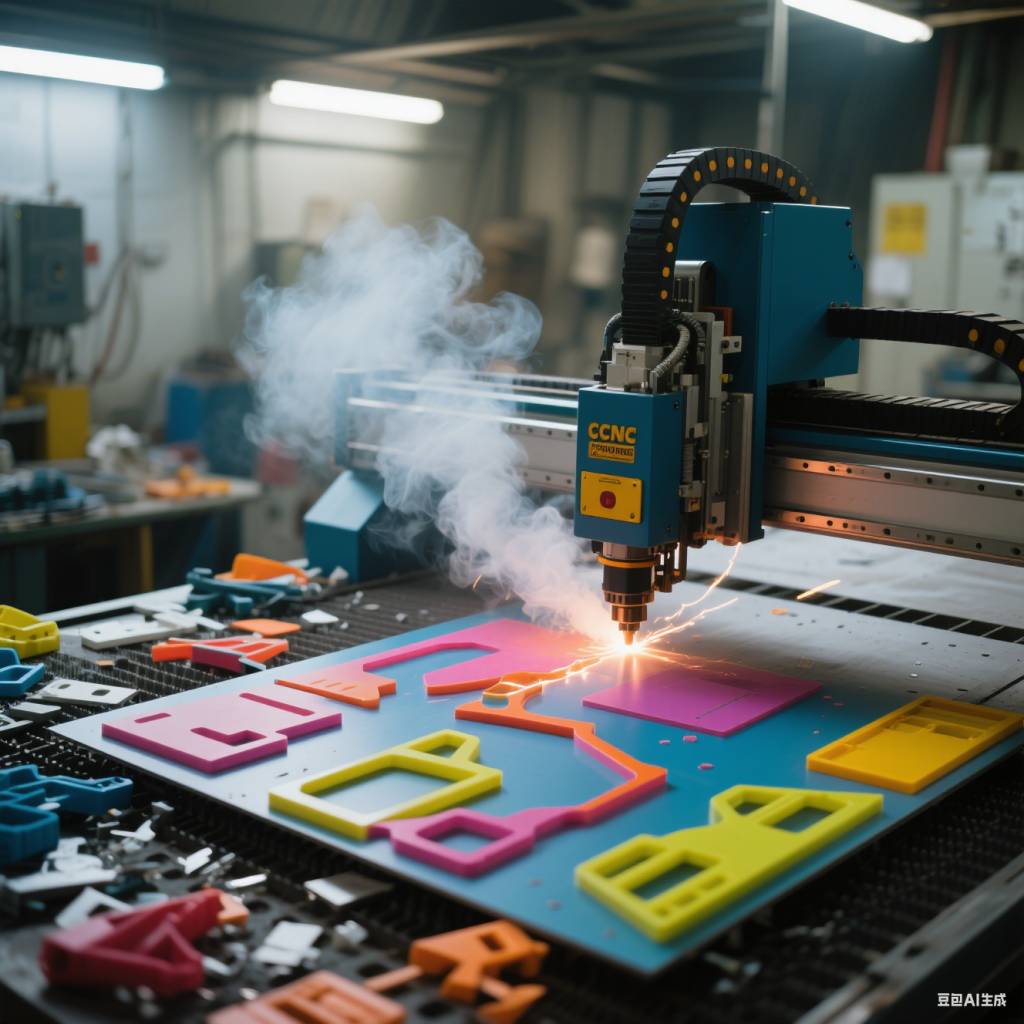

4. Collision – Programming

Causes:

- Inadequate safety height or no safety height set (G00 rapid feed causes tool/chuck to hit the workpiece).

- Mismatch between the tool listed on the program sheet and the actual program.

- Errors in tool length (cutting edge length) or machining depth on the program sheet.

- Mistakes in Z-axis zeroing values on the program sheet vs. actual settings.

- Incorrect coordinate system setup during programming.

Solutions:

- Measure workpiece height accurately to ensure the safety height is above the workpiece.

- Ensure tool information on the program sheet matches the actual program (use automated program sheets or images for clarity).

- Measure the actual machining depth on the workpiece; specify tool length and cutting edge length clearly (typically, the clamping length should exceed the workpiece by 2–3 mm, and the cutting edge should clear by 0.5–1.0 mm).

- Perform actual Z-axis zeroing on the workpiece and document values carefully (double-check manual entries).

5. Collision – Operator

Causes:

- Incorrect Z-axis depth setting.

- Errors in centering, touching off, or data input (e.g., single-side zeroing without accounting for tool radius).

- Using the wrong tool (e.g., using a D10 tool instead of D4).

- Running the wrong program (e.g., executing A9.NC instead of A7.NC).

- Mismatched handwheel direction during manual operation.

- Incorrect direction when using manual rapid feed (e.g., pressing +X instead of –X).

Solutions:

- Confirm the zeroing position (bottom, top, or analysis surface) when setting Z-axis depth.

- Double-check centering, touching off, and data input results.

- Cross-verify the tool with the program sheet and code before clamping.

- Run programs sequentially in order.

- Improve the operator’s proficiency in manual machine operations.

- Raise the Z-axis above the workpiece before moving rapidly in manual mode.

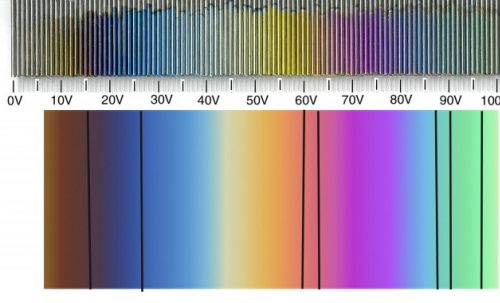

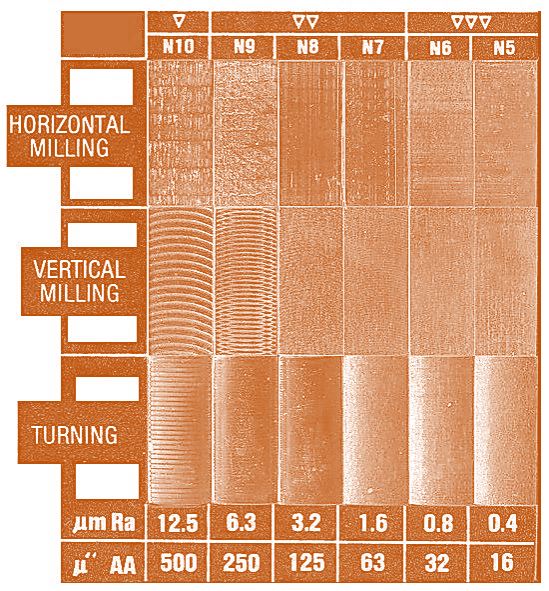

6. Surface Finish Accuracy

Causes:

- Unreasonable cutting parameters leading to rough surfaces.

- Dull tool edges.

- Excessive tool overhang or cutting edge extension.

- Poor chip evacuation, air blowing, or coolant flushing.

- Inappropriate tool path (consider climb milling where possible).

- Workpiece burrs.

Solutions:

- Optimize cutting parameters, tolerance, allowance, spindle speed, and feed rate.

- Regularly inspect and replace tools as needed.

- Minimize tool overhang during clamping; keep cutting edge extension to a minimum.

- Adjust spindle speed and feed rate appropriately for flat-end, R-end, and round-nose tools.

- Burrs are related to machine performance, tool condition, and tool paths. Understand the machine’s capabilities and perform touch-up passes on burr-prone edges.

For more information, contact Debaolong Seiko.

Post Views: 8