If parts are used directly after machining, issues like corrosion and fatigue can be severe, eventually leading to part failure. Thus, even after complete machining, metal surface finishing is used to enhance surface durability. This article introduces different metal surface finishing methods, enabling you to easily select the right approach for specific applications.

What Is Metal Finishing for Machined Parts?

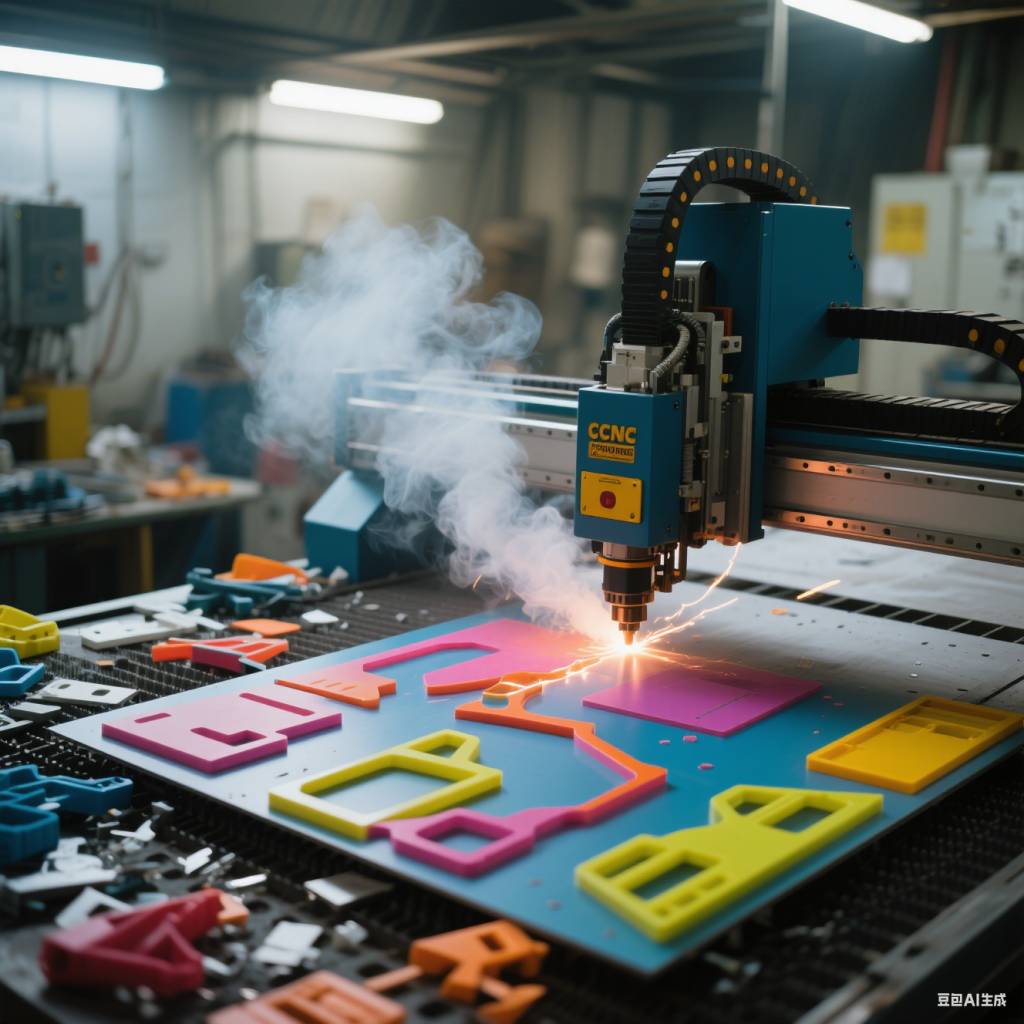

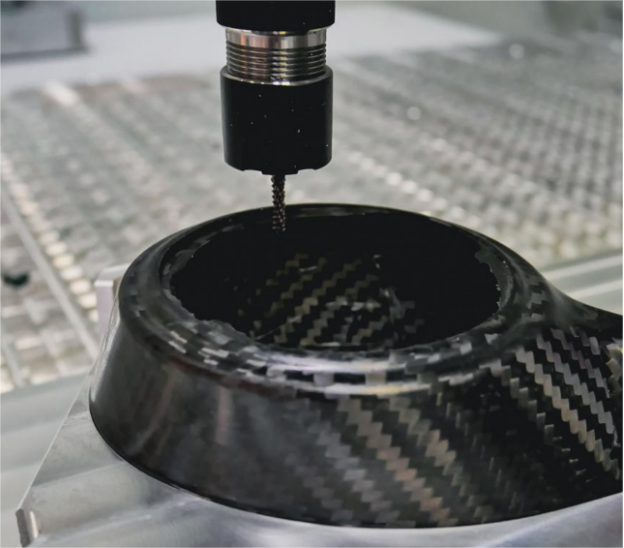

CNC machined parts, despite their fine surface finish, often lack sufficient corrosion resistance under normal conditions. Surface finishing methods like galvanizing form a protective layer on the part surface.

Basics of Post-Machining Surface Finishing

The primary goal of post-machining surface finishing is to enhance surface durability by improving corrosion resistance. Additionally, it provides aesthetic value through coloration.

Why Is Surface Finish Critical for Machined Parts?

Surface finishing enhances wear resistance, corrosion resistance, and aesthetics. Below is a list of finish types and their uses:

| Finish Type | Purpose |

|---|---|

| Anodizing | Corrosion resistance, aesthetics |

| Powder coating | Durability, color variety |

| Passivation | Rust prevention |

| Electroplating | Wear resistance, conductivity |

| Sandblasting | Uniform texture |

| Electroless nickel | Wear/corrosion resistance, even coating |

| Chromate conversion coating | Corrosion protection, paint adhesion |

| Black oxide | Mild corrosion resistance, aesthetic black finish |

| Lapping | Precision surface smoothing |

| Brushed finish | Decorative, scratch-resistant texture |

How Metal Surface Finishing Enhances Part Quality

Improved Corrosion Resistance

Processes like galvanizing form a zinc protective layer, acting as a barrier between the surface and the environment to mitigate corrosion.

Enhanced Surface Hardness and Wear Life

Finishes like nitriding or chrome plating increase hardness, extending wear life.

Better Aesthetics for Visible Parts

For visible components, finishes like polishing or powder coating enhance appearance.

Meeting Functional Surface Requirements

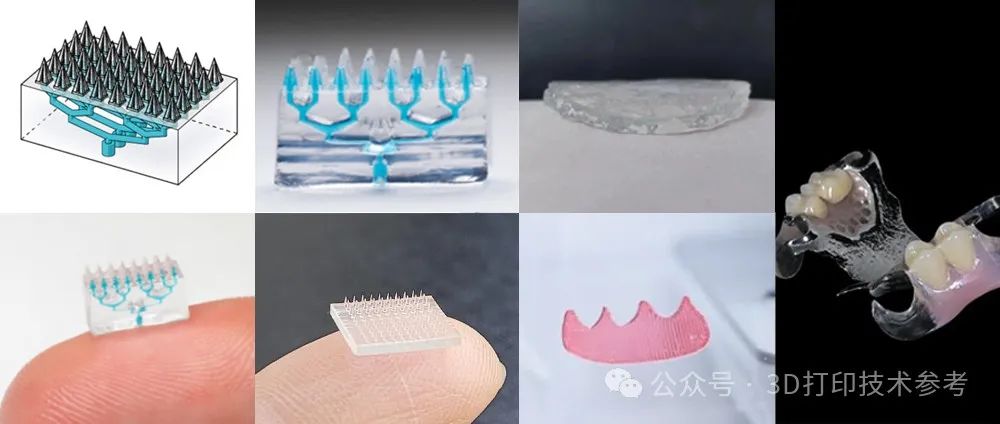

For electronic or medical implant parts, finishes like gold plating are necessary.

Types of Metal Coatings

Additive Coatings (Electroplating, Powder Coating)

Additive coatings deposit materials layer by layer on the substrate:

- Electroplating

- Powder coating

Conversion Coatings (Anodizing, Passivation)

These chemically transform the substrate surface into a protective layer:

- Anodizing

- Passivation

Mechanical Finishing (Polishing, Blasting, Lapping)

This uses physical force to alter surface texture:

- Polishing

- Blasting

- Lapping

Electroplating and Electroless Plating for Machined Parts

These processes apply only to conductive materials, using electric current to deposit metal ions onto the substrate.

Common Electroplated Metals

| Metal | Thickness Range | Main Applications |

|---|---|---|

| Nickel | 5–50μm | Wear resistance, corrosion protection |

| Zinc | 3–25μm | Sacrificial corrosion protection |

| Chromium | 0.3–5μm | Decorative and hard chrome uses |

Metals Unsuitable for Direct Electroplating

Metals like aluminum and its alloys react instantly with oxygen to form Al₂O₃, causing poor adhesion for subsequent layers.

Barrel Galvanizing for Small Parts

An efficient electroplating process for zinc coating on small conductive components, ideal for batch finishing.

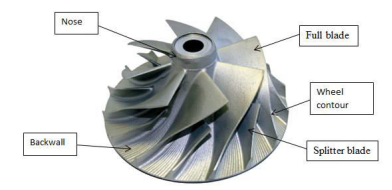

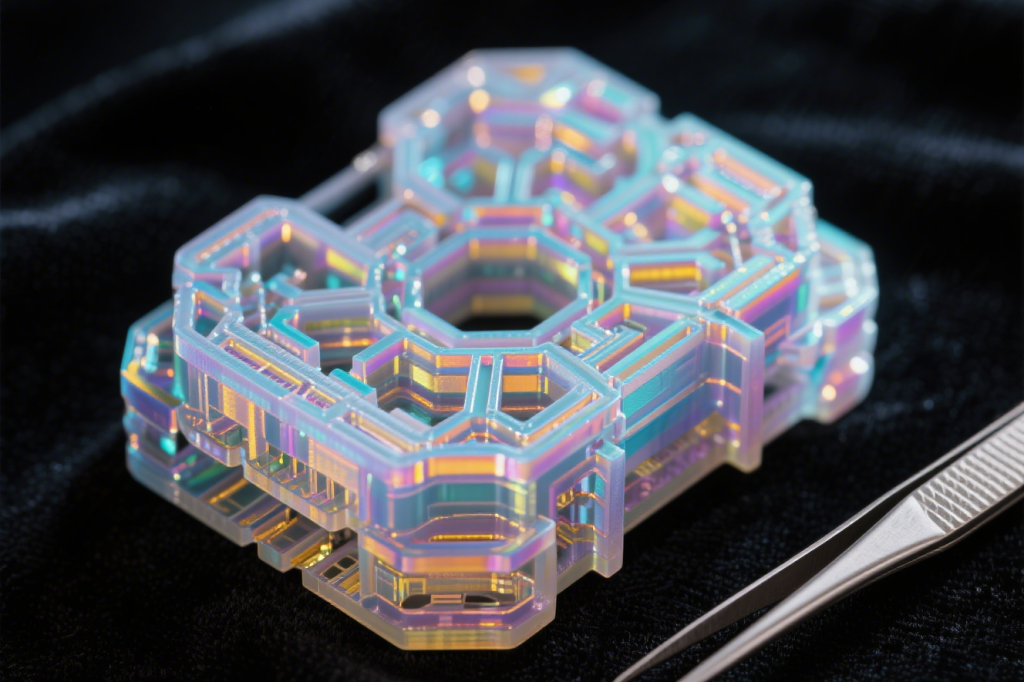

Electroless Plating: Advantages for Complex Geometries

This process coats complex shapes efficiently without electricity, commonly used for electrical connectors and aerospace parts (e.g., electroless nickel plating on Ti-6Al-4V fasteners).

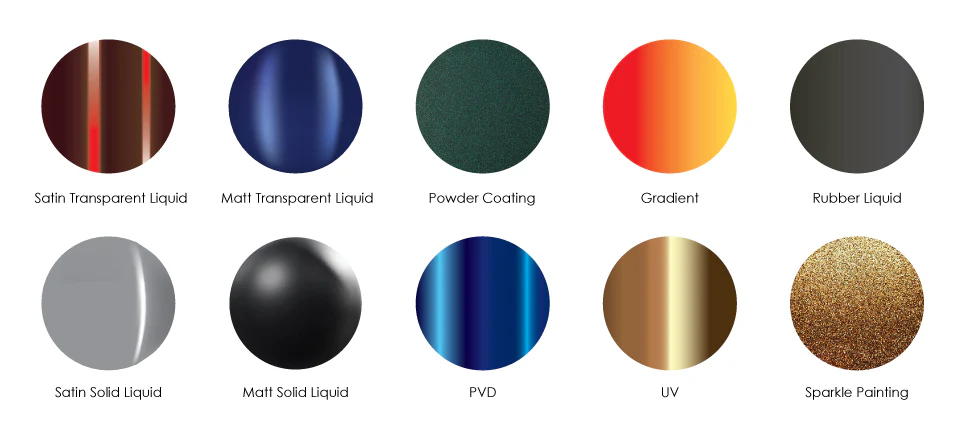

Powder Coating and Painting Options

Powder coating applies powder via electrostatic spraying, contrasting with liquid painting (e.g., dip coating, spray painting, electrostatic wet spraying).

Powder Coating Color Systems

- RAL Classic: Over 190 colors for safety components

- Pantone Matching System: Over 2,300 colors and special metallic finishes

Benefits of Powder Coating

- Enhanced durability

- Superior environmental resistance

- Cost-effectiveness

- Minimal coating material waste

When Liquid Painting Is Preferred

Choose liquid painting for thin films, complex geometries, or temperature-sensitive substrates.

| Aspect | Powder Coating | Liquid Painting |

|---|---|---|

| Coating thickness | 60–120μm | 15–50μm |

| Corrosion resistance | Better | Inferior |

| Salt spray test | Withstands 500+ hours | Reduced durability |

Anodizing and Passivation

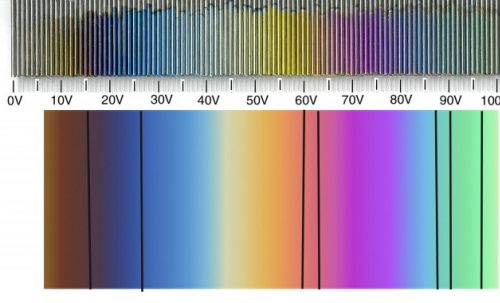

- Anodizing: Deposits a protective oxide layer via an electrochemical process.

- Passivation: Forms a non-reactive protective layer chemically or through surface treatment (sometimes natural oxidation).

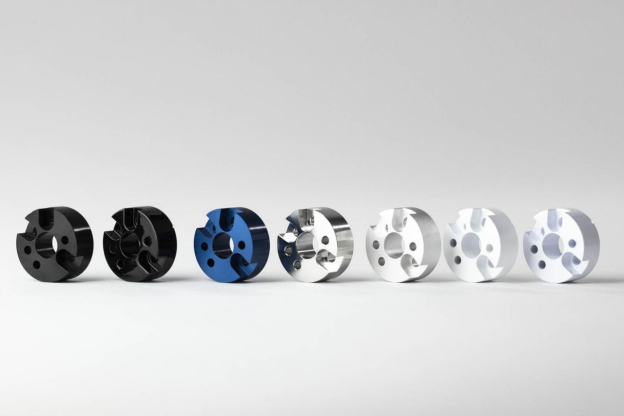

Anodized Aluminum Parts

Used in aerospace for their hard oxide layer.

Anodized Titanium Parts

Ideal for medical implants due to biocompatibility, high hardness, and wear resistance.

Passivated Stainless Steel Parts

Suitable for surgical instruments and food equipment.

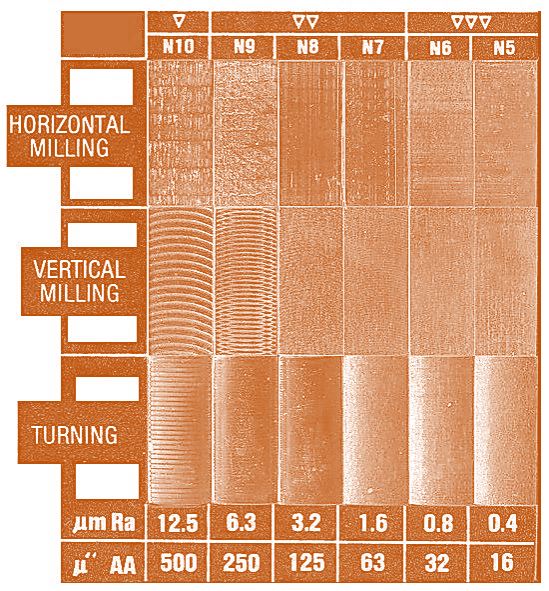

Mechanical Surface Finishing for Machined Parts

Mechanical finishing alters surfaces using abrasives or cutting forces. Key operations for texture control:

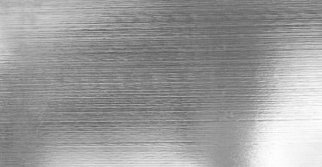

Brushed Metal Finish

Uses grinding wheels or belts to create linear texture patterns (Ra 0.4–1.6μm), common in panels and architectural decor.

Satin Metal Finish

Achieves low-gloss texture (Ra 0.2–0.8μm) with uniform abrasion (e.g., Scotch Brite belts), used in medical devices and food processing equipment.

Matte Metal Finish

Blasts with fine glass beads for non-reflective, frosted surfaces (Ra 0.1–0.4μm), suitable for optical and military instruments.

| Characteristic | Brushed | Satin | Matte |

|---|---|---|---|

| Reflectivity | Directional gloss | Soft sheen | Non-reflective |

| Fingerprint hiding | Poor | Moderate | Excellent |

High-Gloss Finishes

- Polishing: Uses sandpaper (coarse to fine) for a mirror-like effect.

- Buffing: Employs cotton wheels with compounds (e.g., white rouge for stainless steel, green rouge for titanium) for final shine.

Uniform Surface Conditioning

- Sandblasting: Uses fine glass beads for uniform surfaces (Ra 1.5–3.2μm).

- Shot Blasting: Uses aluminum oxide beads to create rough surfaces for painting.

- Electropolishing: Achieves ultra-smooth, contamination-free surfaces for semiconductors and pharmaceutical equipment.

Selecting the Right Metal Finish for Your Parts

Key factors to consider:

- Environment: Choose anodizing for harsh conditions (e.g., seawater).

- Functionality: Opt for electropolishing for mirror finishes.

- Required texture: Use sandblasting for rough surfaces before painting.

- Base metal: Understand compatibility (e.g., aluminum, steel, titanium).

- Preparation needs: Ensure the part is ready for the process.

- Cost: Align the finish with your budget.

Debaolong Seiko offers end-to-end solutions for machined parts, from design to machining and perfect surface finishing—delivering cost-effective services unmatched in the industry.