This article explores various post-processing operations, applications, and advantages/disadvantages of parts printed via SLS and MJF. As powder-based 3D modeling technologies, SLS and MJF create components from thermoplastics and elastomers. Like many manufacturing methods, post-processing completes the fabrication process for SLS and MJF.

Post-processing operations on SLS and MJF 3D printed parts serve multiple purposes: improving surface finish, enhancing mechanical properties, boosting aesthetics, or even achieving conductivity. Another reason for post-processing is that certain materials with certain desired properties cannot be used for SLS or MJF printing. The available materials are processed to give them the desired properties.

Debossing and Shot Peening

This is a standard procedure for printed parts. After printing and cooling, components are removed from the build platform, and powder is brushed off. Since SLS and MJF do not require support structures, removing supports—critical in other 3D printing technologies—is unnecessary. Post-debossing, parts are blasted with high-pressure compressed air containing tiny glass beads to remove residual powder.

Media Tumbling

Also known as vibratory polishing, media tumbling is a finishing process where printed parts are placed in a vibrating tumbler with small ceramic chips for several hours. As the tumbler vibrates, the chips abrade the parts, gradually polishing the outer surface. This reduces roughness and achieves a smooth satin finish, though its mechanism may slightly wear the dimensions of parts with fine details.

Advantages:

• Creates a smooth satin surface finish

• Processes multiple parts simultaneously

Disadvantages:

• Unsuitable for parts with complex details, which may wear down

Dyeing

Dyeing is a faster and more cost-effective way to color SLS and MJF printed parts, primarily for aesthetic improvement. Acidic dyes are used in a heated water bath: parts are immersed for ~10 minutes to ensure proper penetration. Like media tumbling, multiple parts can be dyed simultaneously.

Dyeing does not fully saturate parts, as the dye penetrates only 0.5 mm deep. This becomes evident if parts have deep scratches or incisions. SLS nylon is typically printed white or gray and can be dyed various colors, while MJF parts print gray but are jet-black beneath the surface, making them often dyed black.

Advantages:

• Wide color options, especially for SLS parts

• Does not affect part dimensions

• Processes multiple parts simultaneously

Disadvantages:

• Does not improve surface smoothness

• Dye layer (0.5 mm) can be sanded off

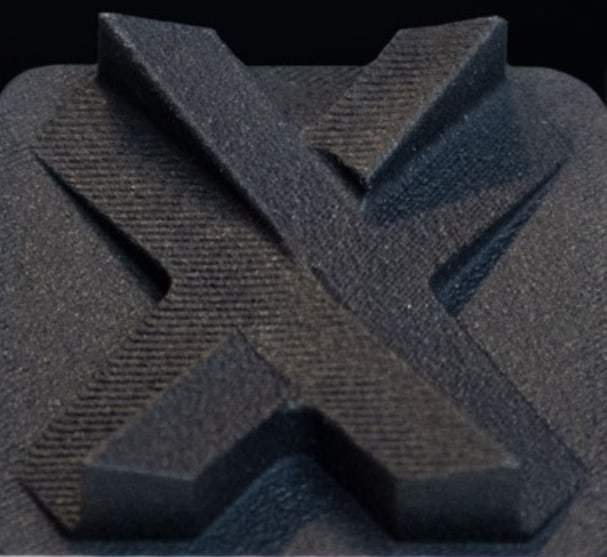

Dyed black MJF nylon PA12

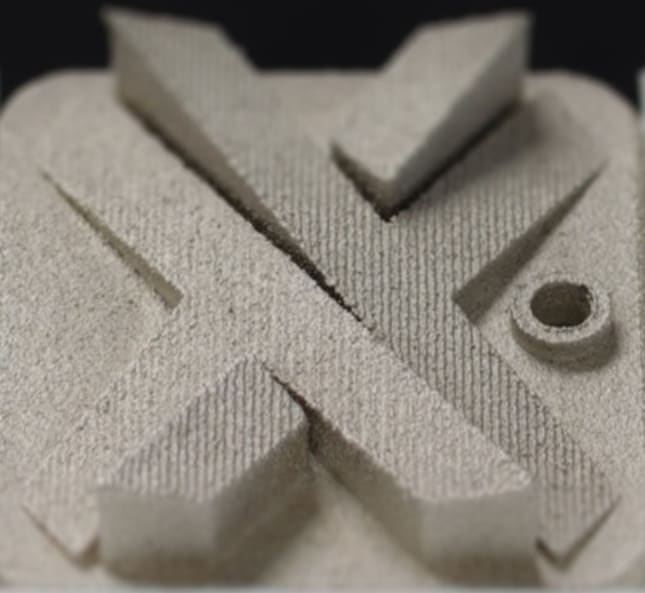

Dyed green SLS nylon PA12

Painting and Coating

Painting and coating achieve various aesthetic finishes (e.g., metallic or high gloss) and enhance water tightness, surface hardness, and wear resistance. Due to the porosity of MJF and SLS parts, multiple thin paint layers are applied instead of one thick layer.

Advantages:

• Enhances visual glossiness

• Improves physical properties

Disadvantages:

• Parts must be processed individually

• Requires meticulous surface pre-treatment

Waterproofing

Properly printed SLS and MJF parts have reasonable water resistance. To further enhance this, coatings like silicone or acrylic vinyl are applied.

Advantages:

• Provides excellent water resistance

Disadvantages:

• Thick coatings may affect part dimensions

Metal Plating

SLS and MJF parts can be metal-plated to increase strength and conductivity, using materials like copper, gold, nickel, chromium, or stainless steel. Plating occurs via electroplating: metal dissolves in a solution, and electric current bonds metal particles to the part’s surface.

Advantages:

• Enhances strength and conductivity

• Creates an excellent surface finish

Disadvantages:

• May increase part weight

• More expensive than other coating methods

Nickel plated nylon PA12

Nickel-Plated Nylon PA12

Conclusion

At Debaolong Seiko, we offer a range of post-processing services for your SLS and MJF 3D printed parts. Visit our Debaolong Seiko, upload your model, and get a quote for your components.