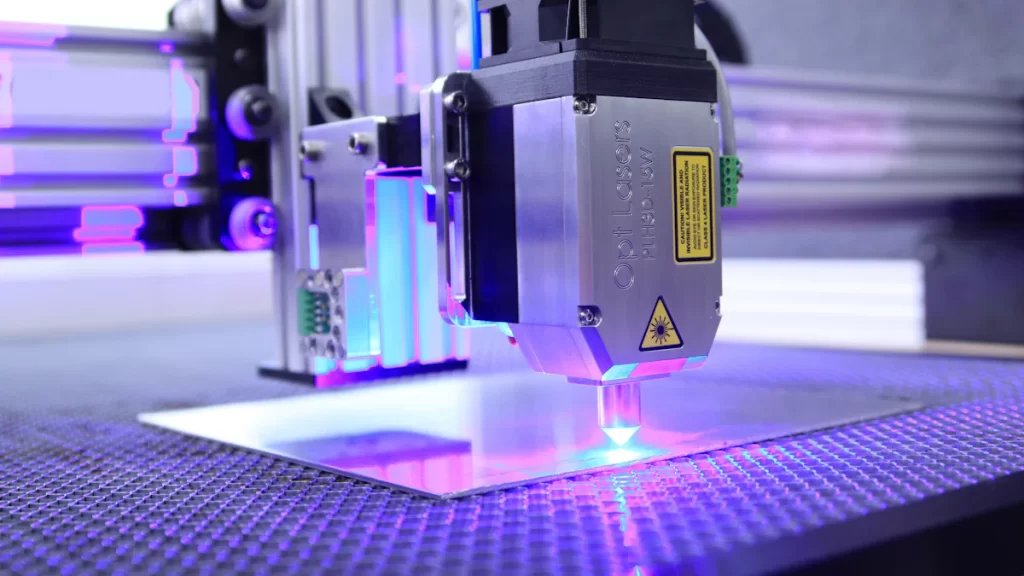

Just a few years ago, 3D printing was an unattainable dream, rarely used even in industrial fields or for prototyping. Today, technology has permeated all aspects of life—from electronic device casings to creative handicrafts—making 3D printing a necessity for both professional designers and hobbyists.

Why Is 3D Printing Popular Among Consumers?

Easy Customization

3D printing enables convenient customization. For example, previously, getting a pair of well-fitting headphones required costly and time-consuming custom orders, often resulting in one ear fitting poorly. 3D printing solves this: it can create not only headphones but also wearable devices like watches, shoes, and more.

Rapid Prototyping

Jewelry designers can now visualize their designs as physical prototypes via 3D printing at just 1/20th of the original cost. This applies to all consumer products, from inexpensive PET bottles to luxury jewelry. Technologies like Fused Deposition Modeling (FDM) excel in efficient prototyping, while Stereolithography (SLA) offers high-resolution results.

3D Printing in Consumer Goods

Additive manufacturing in consumer sectors can be divided into two main categories:

Commercial Applications of 3D-Printed Consumer Products

When consumers purchase 3D-printed products, they acquire ready-made items rather than creating them step-by-step. Examples include:

3D-Printed Eyewear

Canadian eyewear manufacturer Specsy has successfully applied 3D printing to the optical industry. Using an AI program to scan customers’ faces, they customize glasses to exact measurements and preferences, employing Selective Laser Sintering (SLS) for complex designs. Finished components are assembled and delivered to customers.

3D printed eyewear

3D-Printed Dental Aligners

U.S. tele-dentistry company SmileDirectClub partners with HP to produce clear dental aligners using 3D-printed molds of customers’ teeth. After providing a “home impression kit” and digital photos, HP’s Multi-Jet Fusion (MJF) 3D printers precisely fabricate aligners and transparent retainers based on customer data.

3D printed dental aligner

3D-Printed Insoles

Famous footwear brand Dr. Scholl’s uses additive manufacturing for custom insoles. Collaborating with tech firm Wiivv, they scan customers’ feet via the Wiivv Fit app, mapping 400 reference points to calculate exact foot shapes and sizes. Custom insoles are printed and delivered, with FDM technology enhancing efficiency and reducing costs.

3D printed insoles

3D-Printed Mascara Brushes

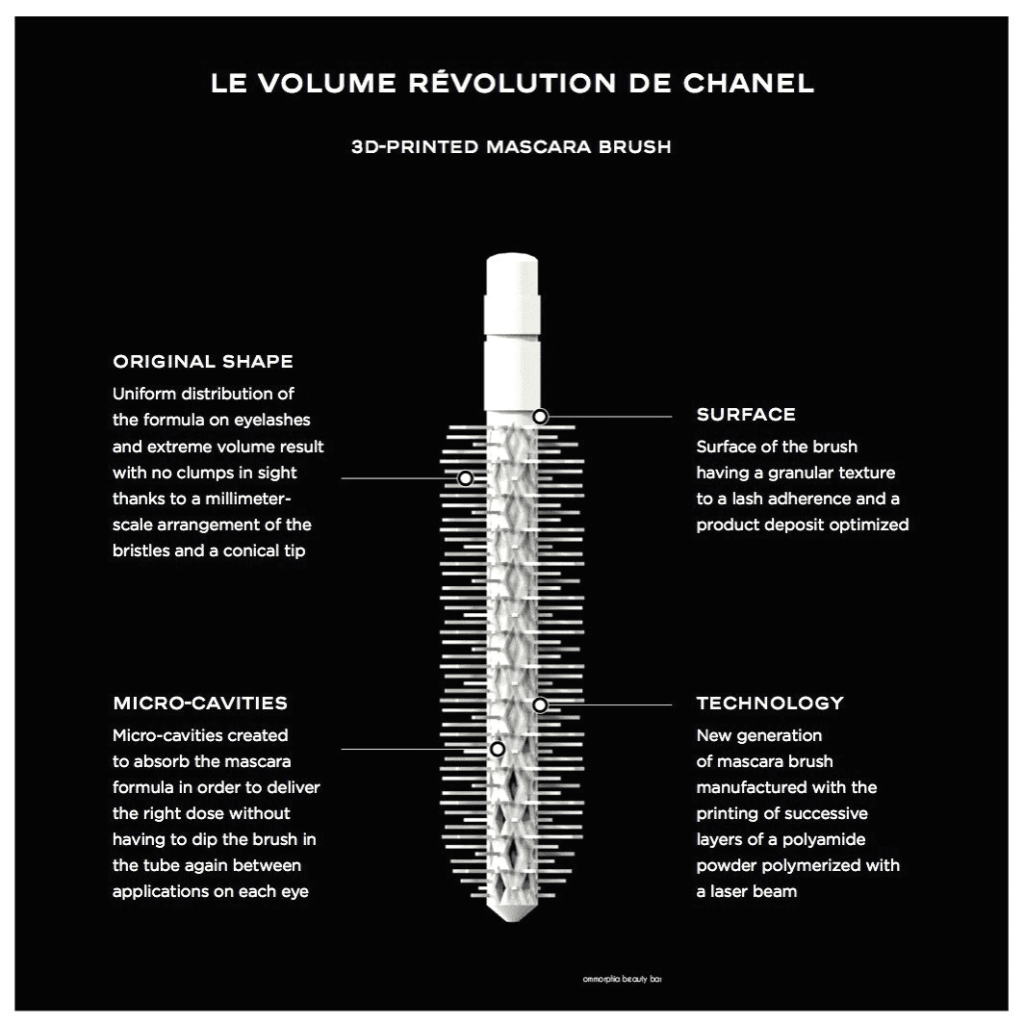

Luxury cosmetics brand Chanel uses Selective Laser Sintering (SLS) to mass-produce its exclusive mascara brushes. Through additive manufacturing, Chanel’s design team has undergone 100+ iterations. The brush’s unique micro-cavities absorb more mascara, reducing dips, while textured bristles ensure even application.

3D printing mascara brush

3D-Printed Razors

Personal care brand Gillette uses SLA technology to produce custom razor handles, tailored to individual needs for optimal grip and durability.

3D printing shaving razors

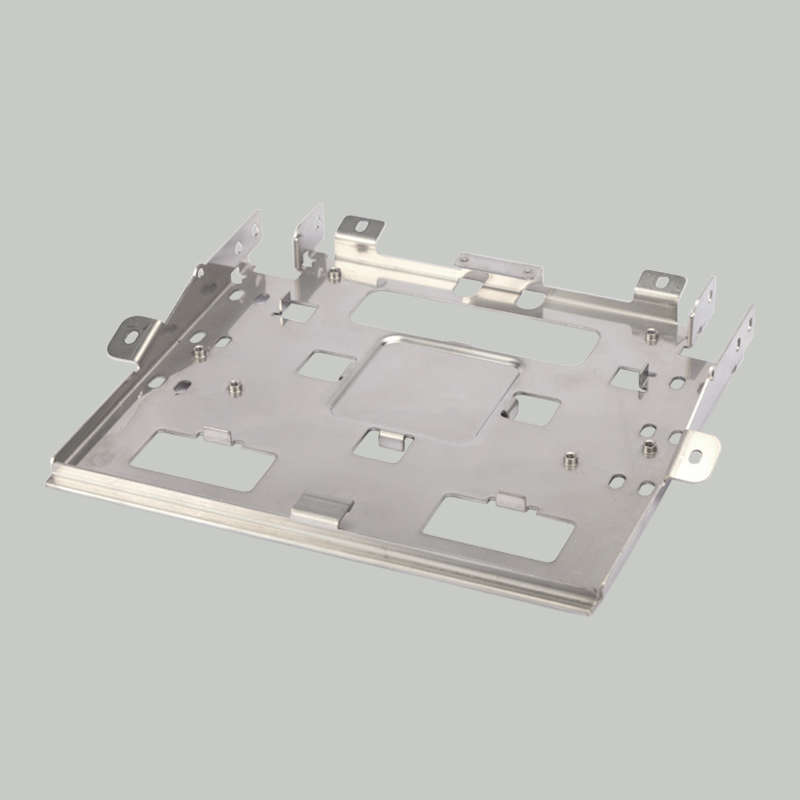

3D-Printed Bicycle Components

Reynolds Technology Ltd and Renishaw PLC have created a stainless-steel bike frame with optimized 3D-printed parts, as well as titanium frames and dropouts using metal 3D printing. Additive manufacturing allows hollow designs, reducing weight and improving efficiency.

3D printing bicycle frame

3D-Printed Bike Helmets

London’s Hexr Helmet Company produces bike helmets via additive manufacturing. Featuring a honeycomb structure, helmets are customized to fit each customer’s head shape and size. Nylon material combined with SLS technology makes them lightweight, functional, and proven to be some of the sturdiest on the market.

3D printed bike helmet from Hexr

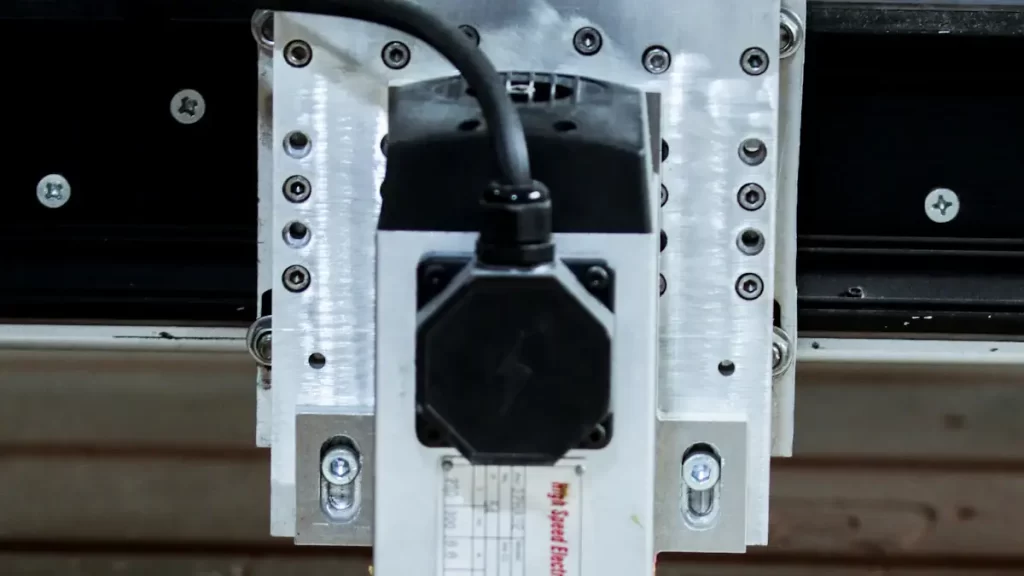

How Customers Use 3D Printers

This section highlights in-house 3D printing by customers, including:

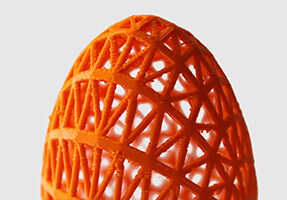

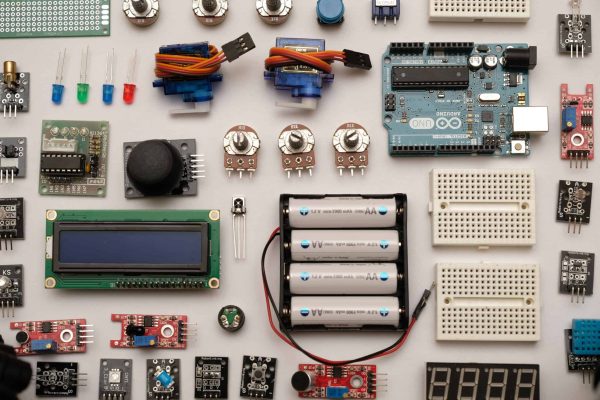

Desktop 3D Printing

Beyond expensive industrial printers, affordable and efficient desktop models cater to designers and hobbyists. Entry-level FDM printers cost around €200, offering vast potential for innovation and customization. Desktop SLA printers are slightly pricier but accessible with basic design knowledge and usage tips.

A water bottle holder made by a private customer

Digital Fabrication

3D printing requires minimal design skills—simply download a design and follow instructions. Simple creations like the water bottle holder above, along with vases, phone cases, etc., are widely available online.

Conclusion

3D printing simplifies complex manufacturing, leaving room for innovation in both purchased and self-created products.

Debaolong Seiko offers 3D printing services with a variety of materials. Visit Debaolong Seiko to get a quote and order your 3D printed products!