Metal 3D printing is revolutionizing the manufacturing of complex and highly intricate components by building them layer by layer. This advanced technology offers unmatched precision and design flexibility, enabling the production of lighter, stronger, and more functional parts with ease. Industries like aerospace and healthcare are leveraging its capabilities to deliver customized, high-performance components. The innovation not only minimizes material waste but also significantly accelerates production times. With the metal 3D printing market projected to grow by 38% between 2021 and 2028, it’s undeniable that this technology is shaping the future of manufacturing.

Key Points

- Metal 3D printing transforms manufacturing by creating complex, lightweight, and high-performance parts with unmatched precision.

- The technology minimizes material waste using additive manufacturing, applying metal only where needed, making it a more sustainable choice than traditional methods.

- Industries like aerospace and healthcare benefit immensely from metal 3D printing, enabling customized components such as patient-specific implants and lightweight aerospace parts.

- The process involves critical steps: designing the part, preparing materials, printing, and post-processing—each vital for high-quality results.

- Metal 3D printing accelerates prototyping and iteration, allowing rapid testing and design refinement, thus shortening time-to-market and enhancing innovation.

- While offering advantages, challenges like high initial costs and post-processing needs must be addressed to fully leverage metal 3D printing in mass production.

Understanding Metal 3D Printing

What is Metal 3D Printing?

Metal 3D printing is an advanced manufacturing process that builds components layer by layer using metal powder or wire. Unlike traditional methods, which typically involve cutting or shaping materials from a solid block, this process adds material only where needed. This additive manufacturing approach minimizes waste and allows the creation of complex designs that were once unachievable.

The process starts with a digital 3D model of the part. Specialized machines then fuse metal particles using techniques like laser melting, sintering, or electron beam melting. The result is fully dense, durable components with precise internal and external features. This technology has become a game-changer for industries requiring high-performance parts, such as aerospace, automotive, and healthcare.

How It Differs from Traditional Manufacturing

Metal 3D printing differs from traditional manufacturing in several key ways. First, it eliminates the need for tools, molds, or dies, which are often required in traditional methods. This not only reduces upfront costs but also speeds up production times. Second, it offers unparalleled design freedom, enabling complex geometries, intricate internal channels, and lightweight structures that traditional machining can’t replicate.

Another significant difference lies in material efficiency. Traditional manufacturing often generates substantial waste, especially when machining parts from solid metal blocks. In contrast, metal 3D printing uses only the material needed for the component, making it a more sustainable choice. Additionally, the technology supports on-demand production, reducing the need for large inventories and enabling rapid prototyping and iteration.

“Components manufactured via metal 3D printing are stronger, lighter, and more complex than those from traditional manufacturing methods.”

This capability makes it ideal for applications where performance and precision are critical.

Why It’s Ideal for Complex Parts

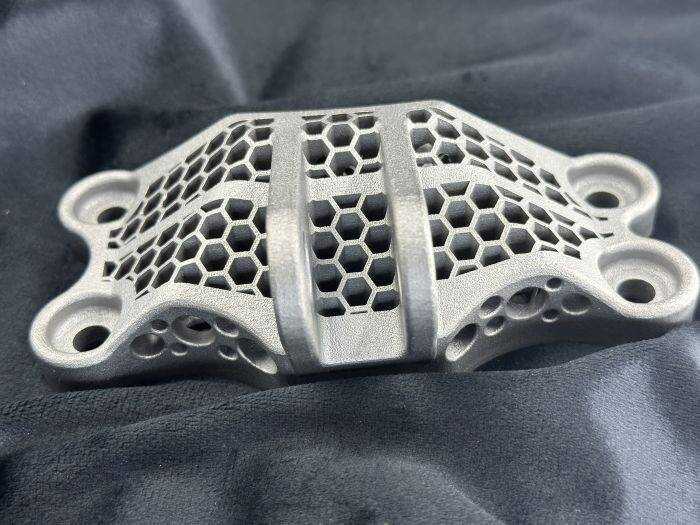

Metal 3D printing excels in producing complex components due to its ability to execute intricate geometries with precision. Traditional methods often struggle with designs that include overhangs, internal cavities, or lattice structures. With 3D printing, these limitations are overcome, enabling designs once considered unfeasible.

The technology also supports customization. You can tailor parts to specific requirements without incurring additional costs or delays. For example, in healthcare, metal 3D printing creates patient-specific implants and prosthetics. In aerospace, it allows lightweight components that improve fuel efficiency without compromising strength.

The speed and reliability of metal 3D printing further enhance its suitability for complex parts. You can quickly generate prototypes, test them, and adjust as needed. This iterative process ensures the final product meets exact specifications while reducing development time.

The Step-by-Step Process of 3D Printing Metal

Step 1: Design the Part

The process begins with creating a digital blueprint of the part using Computer-Aided Design (CAD) software. This allows you to design complex geometries and intricate structures unattainable by traditional manufacturing. Precision is crucial at this stage, as designs must consider factors like material properties, thermal stress, and dimensional tolerances.

For example, in aerospace applications, engineers often design lightweight lattice structures to reduce weight while maintaining strength. These designs drive the industry’s growing reliance on metal 3D printing, which now accounts for 16% of 3D printing market revenue. Once designed, the model is converted to a format compatible with 3D printers, typically an STL file, which slices the model into thin layers to guide the printer during construction.

Step 2: Prepare the Materials

After design, the next step is material preparation. Most metal 3D printers use fine metal powder or wire as raw materials, which must meet strict quality standards to ensure the final part’s strength and durability. Metal powder is loaded into the printer’s build chamber and evenly distributed on the build platform. The consistency of powder layers is vital for achieving uniform density and avoiding defects.

In industries where safety and performance are critical—such as aerospace—material preparation plays a pivotal role. Advances in Selective Laser Melting have enabled the use of high-performance alloys, further reinforcing metal 3D printing’s value in manufacturing critical components.

Step 3: Print the Component

With materials prepared, the actual printing process begins. The printer constructs the part layer by layer according to the digital design, using techniques like Direct Metal Laser Melting (DMLM) or Electron Beam Melting (EBM). These methods involve melting or fusing metal powder using high-energy lasers or electron beams.

Each layer fuses meticulously with the one below, forming a fully dense and durable structure. The process’s precision allows production of parts with complex internal features, such as cooling channels or lattice frameworks. This capability drives adoption in aerospace and automotive industries for manufacturing lightweight, high-performance components.

The printing process also supports rapid prototyping. You can quickly generate and test multiple design iterations, reducing development time and costs. This flexibility fuels the growth of 3D printed metal and continues to revolutionize modern manufacturing.

Step 4: Post-Processing

Post-processing is a critical step in metal 3D printing, ensuring parts meet required quality, functionality, and aesthetic standards. After printing, the raw component typically needs additional work to reach its final form, involving techniques to optimize surface finish, enhance mechanical properties, and prepare it for use.

1. Remove Excess Material

The first task is removing any excess material, including support structures added during printing to stabilize the part and prevent deformation. These supports must be carefully removed without damaging the part, using tools like saws, grinders, or wire cutters. For complex designs, specialized equipment may be needed to access hard-to-reach areas.

2. Heat Treatment

Heat treatment is vital for improving a part’s mechanical properties. The printing process can introduce residual stresses due to rapid heating and cooling cycles. Heat treatment relieves these stresses, enhancing the part’s strength, durability, and dimensional accuracy—especially crucial for aerospace components to ensure they withstand extreme conditions.

“Advances in Selective Laser Melting have made heat treatment indispensable in industries where performance and reliability are critical, such as aerospace and automotive.”

3. Surface Finishing

Surface finishing enhances a part’s appearance and function. The raw surface of 3D printed metal components is often rough due to the layer-by-layer structure. Techniques like sanding, polishing, or blasting smooth the surface for applications requiring high precision. Coatings or plating may be applied to improve corrosion resistance or achieve specific aesthetics.

4. Dimensional Inspection

Dimensional inspection ensures the part meets exact specifications outlined in the design. Advanced tools like Coordinate Measuring Machines (CMM) or laser scanners verify the part’s dimensions and tolerances—critical for industries like aerospace, where even minor deviations affect performance.

Aerospace applications alone account for 16% of 3D printing industry revenue, highlighting precision’s importance in this sector.

5. Assembly and Testing

If the part is part of a larger assembly, post-processing may include fitting it with other components, followed by testing to ensure it functions as intended. For example, in the automotive industry, metal 3D printed parts undergo rigorous testing to validate their strength and functionality under real-world conditions.

Technologies for 3D Printing Metal

Direct Metal Laser Melting (DMLM)

Direct Metal Laser Melting (DMLM) is one of the most advanced methods for manufacturing metal components. This technology uses high-power lasers to selectively melt and fuse layers of fine metal powder, building parts layer by layer to exact digital design specifications. DMLM excels in producing fully dense components with exceptional mechanical properties.

DMLM enables complex geometries and internal features unreachable by traditional manufacturing, making it ideal for industries like aerospace and healthcare, where precision and performance are critical. Its ability to process various metals—including titanium, stainless steel, and aluminum—further enhances its versatility. DMLM also minimizes material waste by using only the powder needed for each component.

“DMLM allows you to create lightweight, high-strength parts with unmatched precision, making it a cornerstone of modern metal 3D printing technology.”

Binder Jetting

Binder Jetting offers a unique approach to metal 3D printing. Instead of melting metal powder, this method uses a liquid binder to bond powder particles together. The printer deposits binder layer by layer, gradually building the part. After printing, the component undergoes a sintering process to remove the binder and fuse metal particles.

Renowned for speed and cost-effectiveness, Binder Jetting allows simultaneous production of multiple parts, making it suitable for mass manufacturing. It supports various materials, including metals, ceramics, and composites. However, final parts may require additional post-processing to achieve full density and optimal mechanical properties.

Binder Jetting is particularly useful for applications prioritizing high-volume production and cost efficiency. For example, in the automotive industry, manufacturers use this method to produce complex components at a fraction of traditional costs.

Electron Beam Melting (EBM)

Electron Beam Melting (EBM) is another cutting-edge technology in metal 3D printing. This method uses high-energy electron beams to melt and fuse metal powder. Unlike DMLM, which operates in laser-based systems, EBM works in a vacuum environment, reducing contamination risks and making it ideal for producing high-purity parts.

EBM is well-suited for applications requiring high-performance materials like titanium and nickel-based alloys. It manufactures parts with excellent strength-to-weight ratios, making it a favorite in aerospace and medical industries. The vacuum environment also allows faster build times compared to other methods.

One of EBM’s main advantages is its ability to process high-temperature materials, enabling production of components that withstand extreme conditions—such as jet engine parts or orthopedic implants. However, EBM parts may require additional post-processing for surface finish to meet specific requirements.

“EBM combines precision with material strength, offering a reliable solution for industries needing high-performance metal components.”

Laser Powder Bed Fusion (LPBF)

Laser Powder Bed Fusion (LPBF) is one of the most precise and widely used methods in metal 3D printing. This technology uses high-power lasers to selectively melt and fuse thin layers of metal powder, creating components with exceptional detail and mechanical strength. You can rely on LPBF to produce complex geometries and lightweight structures unattainable by traditional manufacturing.

How LPBF Works

The LPBF process starts with a thin layer of metal powder evenly distributed on the build platform. The laser then scans the surface, melting specific areas of powder according to your digital design. Once the laser completes a layer, the platform lowers slightly, and a new powder layer is applied. This cycle repeats until the part is fully constructed.

The laser’s precision allows creation of parts with tight tolerances and complex internal features. LPBF supports multiple metals—including titanium, aluminum, and stainless steel—making it suitable for various industries.

Key Advantages of LPBF

- Unmatched Precision: LPBF delivers exceptional accuracy, enabling parts with intricate details and smooth surfaces—ideal for applications requiring high precision, such as aerospace components or medical implants.

- Material Efficiency: The process uses only the material needed for the part, significantly reducing waste and enabling sustainable production.

- Design Freedom: LPBF allows creation of complex geometries, including lattice structures and internal channels, which enhance functionality while minimizing weight.

- Wide Material Compatibility: You can use various metals, from lightweight aluminum to high-strength alloys, ensuring LPBF meets diverse industry needs.

Applications of LPBF

LPBF has revolutionized industries by producing high-performance parts. In aerospace, it manufactures lightweight components that improve fuel efficiency. In healthcare, LPBF enables patient-specific implants and prosthetics. Automakers leverage the technology to produce durable, lightweight parts that enhance vehicle performance.

“LPBF combines precision, efficiency, and versatility, making it a cornerstone of modern metal 3D printing technology.”

Design Considerations for 3D Printing Metal

Achieving Design Freedom

Metal 3D printing offers unmatched design freedom, enabling complex geometries and intricate structures impossible with traditional manufacturing. The technology eliminates mold and tooling limitations, allowing focus on innovation. You can design parts with internal channels, lattice structures, or overhangs without worrying about subtractive method constraints.

Technologies like Direct Metal Laser Melting (DMLM) and Selective Laser Melting (SLM) let you produce parts with 99% density and strength comparable to forged components—ideal for industries like aerospace, where lightweight and durable designs are critical. By leveraging these technologies, you can push the boundaries of part design possibilities.

“With metal 3D printing, you can bring even the most ambitious designs to life, achieving complexity once unreachable.”

To maximize design freedom, use advanced Computer-Aided Design (CAD) software to visualize and refine ideas before production. Also, consider the material properties and specific 3D printing method you plan to use, as each technology—such as Binder Jetting or Direct Energy Deposition—has unique capabilities influencing design choices.

Optimizing for Lightweight Structures

One of metal 3D printing’s most significant advantages is creating lightweight structures without compromising strength. You can achieve this by incorporating lattice frameworks or hollow sections into designs, reducing material use while maintaining part mechanical integrity.

Technologies like DMLM excel in producing lightweight components with high strength-to-weight ratios. For example, in aerospace applications, you can design parts that improve fuel efficiency by reducing weight. Similarly, in the automotive industry, lightweight structures enhance performance and energy savings.

To optimize for lightweight structures, focus on:

- Lattice Design: Use CAD tools to create complex lattice patterns that distribute stress evenly across the part.

- Material Selection: Choose high-performance alloys like titanium or aluminum, which offer excellent strength while being lightweight.

- Simulation Tools: Use simulation software to analyze stress distribution and ensure designs meet performance requirements.

“Optimizing for lightweight structures allows cost reduction, efficiency improvement, and unlocks new possibilities in product design.”

Managing Support Structures and Overhangs

Support structures play a crucial role in metal 3D printing, especially for handling overhangs or complex geometries. These temporary structures stabilize the part during printing, preventing deformation and ensuring dimensional accuracy. However, managing support structures effectively is vital to minimize material waste and post-processing effort.

When designing for metal 3D printing, you should:

- Minimize Overhang Angles: Keep overhangs below 45 degrees whenever possible to reduce support needs.

- Use Self-Supporting Designs: Incorporate features like arches or domes that can support themselves during printing.

- Plan for Easy Removal: Design supports that are easily accessible and removable without damaging the part.

Technologies like Binder Jetting simplify support structure management by using liquid binders instead of melting metal powder, reducing post-processing complexity and making high-quality results easier to achieve. Advances like Desktop Metal PureSinter also enable precise sintering, further improving support removal efficiency.

“Effective management of support structures ensures final products meet both functional and aesthetic standards.”

Material-Specific Design Constraints

When designing for metal 3D printing, you must consider each material’s unique constraints. Every metal behaves differently during printing, affecting the final part’s quality, strength, and functionality. Understanding these constraints helps optimize designs for best results.

1. Thermal Properties

Metals like titanium, aluminum, and stainless steel have different thermal characteristics influencing their reaction to heat during printing. For example, titanium has a high melting point and excellent strength-to-weight ratio, making it ideal for aerospace applications. However, its thermal conductivity can cause warping if mismanaged. Consider these properties in design to minimize thermal stress and ensure dimensional accuracy.

“Direct Metal Laser Melting (DMLM) and Selective Laser Melting (SLM) technologies excel in handling high-performance metals like titanium, producing parts with 99% density and strength comparable to forged components.”

2. Material Density and Strength

A material’s density and strength directly impact part performance. Lightweight metals like aluminum suit applications needing weight reduction, such as automotive components. Denser metals like stainless steel offer superior durability and corrosion resistance, making them suitable for medical implants or industrial tools. Adjust material selection to meet application-specific requirements.

3. Sintering and Post-Processing Needs

Some materials require extra post-processing to reach full potential. For example, Binder Jetting often involves a sintering step to remove the binder and fuse metal particles. Advanced systems like Desktop Metal PureSinter can sinter titanium to 98% density, ensuring high-quality results. Plan these additional steps to meet required specifications when using such materials.

4. Compatibility with Printing Technologies

Not all materials are compatible with every 3D printing technology. For example:

- DMLM and SLM are ideal for high-strength alloys and complex geometries.

- Binder Jetting supports high-volume production but may require more post-processing.

- Direct Energy Deposition is great for repairing or adding features to existing parts using materials like metal powder or wire.

Choose a technology aligned with material properties and project goals.

5. Surface Finish and Aesthetic Requirements

A part’s surface finish depends on material and printing method. Metals like stainless steel often need polishing or coating for a smooth, visually appealing surface. If your application requires specific aesthetic or functional finishes, incorporate these requirements into design and post-processing plans.

“Technologies like Binder Jetting offer excellent printing quality but may need additional finishing steps to meet high aesthetic standards.”

Advantages of 3D Printing Metal

Precision and Accuracy

Metal 3D printing delivers unmatched precision and accuracy, enabling components with complex details and tight tolerances. The technology builds components layer by layer, ensuring every feature aligns perfectly with the digital design. Unlike traditional manufacturing methods, which often struggle with complex geometries, metal 3D printing excels in producing highly detailed structures.

Technologies like Direct Metal Laser Melting (DMLM) and Laser Powder Bed Fusion (LPBF) enable exceptional dimensional accuracy by using high-power lasers to selectively melt metal powder, ensuring each layer fuses seamlessly with the one below. This precision makes metal 3D printing ideal for industries like aerospace and healthcare, where even minor deviations affect performance.

“With metal 3D printing, you can produce components meeting the strictest quality standards, ensuring reliability and functionality in critical applications.”

Leveraging this precision reduces errors, minimizes rework, and ensures parts function as intended—whether manufacturing lightweight aerospace components or customized medical implants.

Reduced Material Waste

Traditional manufacturing methods like machining often generate significant material waste, involving cutting or shaping parts from solid metal blocks and leaving excess material that can’t always be reused. Metal 3D printing, however, uses an additive manufacturing approach, applying material only where needed.

This efficiency reduces waste and lowers production costs. For example, Laser Powder Bed Fusion (LPBF) spreads a thin layer of metal powder on the build platform, and the laser melts only required areas. Unused powder remains intact for recycling in future builds. This sustainable approach aligns with modern manufacturing goals, helping minimize environmental impact while maximizing resource utilization.

“By adopting metal 3D printing, you can achieve sustainable production without compromising quality or performance.”

Reduced material waste also benefits industries like automotive and aerospace, where lightweight designs are critical. Optimize design strength and functionality while using less material for cost-effective, eco-friendly production.

Customization and On-Demand Production

Metal 3D printing enables creation of customized components tailored to specific needs. Unlike traditional methods, which often require expensive molds or tools, this technology produces unique designs without additional setup costs. Modify digital models easily to meet personalized requirements, making customization efficient and economical.

In healthcare, use metal 3D printing to produce patient-specific implants and prosthetics that fit perfectly, enhancing comfort and functionality. In aerospace, design parts optimized for specific performance criteria, such as lightweight structures or enhanced durability.

On-demand production is another significant advantage. With metal 3D printing, manufacture components as needed, eliminating the need for large inventories. This flexibility reduces storage costs and shortens lead times, enabling quick response to changing demands. Advanced systems like HT1001P-2, renowned for scalability, further enhance efficient part production.

“Customization and on-demand production redefine manufacturing, enabling you to deliver tailored solutions quickly and precisely.”

Leverage these capabilities to stay competitive in dynamic markets, offering innovative products that meet customers’ unique needs.

Faster Prototyping and Iteration

Metal 3D printing accelerates prototyping, turning ideas into reality faster than ever. Traditional manufacturing involves lengthy setup times, including tool and mold creation. With metal 3D printing, bypass these steps, generating prototypes directly from digital designs, shortening lead times and streamlining development cycles.

The layer-by-layer structure of metal 3D printing allows quick testing and design refinement. If adjustments are needed, modify the digital model and print new iterations without significant delays. This iterative approach fosters innovation by enabling experimentation with different geometries, materials, and functions.

“Rapid prototyping with metal 3D printing allows you to test concepts, identify flaws, and refine designs in record time.”

For industries like aerospace and automotive, where precision and performance are critical, faster prototyping delivers significant advantages. Validate designs early in development, minimizing costly errors and ensuring final products meet exact specifications.

Advanced systems like HT1001P-2, while primarily designed for plastic Laser Powder Bed Fusion, highlight the potential of large-scale additive manufacturing systems. These technologies allow simultaneous generation of multiple prototypes, saving time and resources.

Applications of 3D Printing Metal

Aerospace Industry

The aerospace industry has embraced metal 3D printing to overcome challenges in weight reduction, performance optimization, and design complexity. Use this technology to create lightweight components that maintain structural integrity in extreme conditions. For example, lattice structures and hollow geometries reduce weight without compromising strength—critical for fuel efficiency and payload capacity.

Metal 3D printing also enables production of complex cooling channels inside turbine blades, improving heat dissipation and enhancing engine performance and durability. Traditional manufacturing methods struggle to achieve such precision and complexity. Additionally, the ability to work with high-performance alloys like titanium ensures parts meet aerospace applications’ strict requirements.

“Metal 3D printing’s capability to produce lightweight, high-strength components is revolutionizing aerospace engineering.”

The iterative nature of 3D printing accelerates prototyping and testing, allowing quick design optimization and reducing development time and costs. This flexibility makes metal 3D printing an indispensable tool for aerospace manufacturers aiming to innovate and stay competitive.

Automotive Industry

In the automotive sector, metal 3D printing has transformed design and production. The technology enables manufacturing lightweight components that enhance vehicle performance and fuel efficiency. Design optimized suspension components or engine parts to reduce weight and improve functionality.

Customization is another significant advantage. Metal 3D printing produces custom parts for high-performance vehicles or limited-edition models, modifying designs to meet specific requirements without extra mold costs. This capability streamlines production and supports on-demand manufacturing.

“The automotive industry leverages metal 3D printing for cost-effective customization and superior performance.”

Also, use metal 3D printing to produce tools and molds with complex geometries, improving manufacturing efficiency and shortening lead times. By adopting this technology, automakers can innovate faster and bring high-quality products to market.

Healthcare Industry

The healthcare sector benefits from the precision and customization metal 3D printing offers. Create patient-specific implants and prosthetics that fit perfectly, enhancing comfort and functionality. For example, titanium implants produced via 3D printing offer excellent biocompatibility and strength, making them ideal for orthopedic and dental applications.

Metal 3D printing also supports production of surgical instruments with complex designs, improving precision during procedures and enhancing patient outcomes. Additionally, the ability to produce small batches of customized devices ensures unique medical needs are met efficiently.

“Metal 3D printing empowers healthcare professionals to deliver personalized solutions, advancing patient care.”

In research, metal 3D printing creates chemical reactors and catalysts for innovative medical applications, highlighting the technology’s potential to drive breakthroughs in healthcare and beyond.

Other Industries

Metal 3D printing has expanded its transformative capabilities to a wide range of industries beyond aerospace, automotive, and healthcare. Leverage the technology to innovate in energy, chemical processing, consumer goods, and more. Its ability to create complex geometries, reduce waste, and accelerate production makes it a valuable tool for solving intricate manufacturing challenges.

Energy Industry

In energy, metal 3D printing plays a key role in improving efficiency and sustainability. Use it to produce components for turbines, heat exchangers, and fuel cells, which often require complex internal channels for optimal performance—hard to achieve with traditional manufacturing. For example, turbine blades with advanced cooling designs can increase energy output while reducing wear.

The technology also supports developing renewable energy solutions, manufacturing lightweight, durable components for wind turbines or solar panel mounts, ensuring long-term reliability. By adopting metal 3D printing, the energy sector can reduce costs, enhance performance, and contribute to a more sustainable future.

Chemical Processing

Metal 3D printing revolutionizes chemical processing by producing highly specialized equipment. Design and manufacture chemical reactors and catalysts with precise geometries to optimize reactions. Research published in Nature shows 3D printed products can act as catalysts for converting C1 molecules into high-value chemicals, opening new possibilities for efficient and sustainable chemical processes.

Additionally, produce corrosion-resistant components for harsh environments using materials like stainless steel and nickel-based alloys, ensuring durability and longevity while reducing maintenance costs. Integrating metal 3D printing into chemical processing achieves higher efficiency and innovation.

Consumer Goods

The consumer goods industry benefits from metal 3D printing’s customization and design flexibility, creating unique, high-quality products tailored to individual preferences. Jewelry, watches, and luxury goods often feature complex designs hard to produce with traditional methods, which metal 3D printing achieves precisely and efficiently.

Also, use the technology to manufacture durable, lightweight components for sports equipment, such as bicycle frames or golf club heads, combining performance with aesthetic appeal to meet modern consumer demands. By adopting metal 3D printing, the consumer goods industry can offer innovative, personalized solutions.

“Metal 3D printing enables industries to push design and functionality boundaries, creating products once thought impossible.”

Challenges and Limitations of 3D Printing Metal

High Initial Costs

Metal 3D printing requires significant upfront investment. For many businesses, the cost of purchasing advanced 3D printers—such as those using Direct Metal Laser Melting (DMLM) or Electron Beam Melting (EBM)—can be prohibitive, typically ranging from hundreds of thousands to millions of dollars. Costs extend beyond the printer to include auxiliary equipment like material handling systems, post-processing tools, and quality control devices.

Raw material costs also add to the financial burden. Metal powders used in 3D printing must meet strict quality standards, making them more expensive than traditional bulk materials. For example, titanium powder commonly used in aerospace and medical applications can cost significantly more than forged or cast titanium.

“The high initial costs of metal 3D printing may deter small and medium-sized enterprises from adopting this transformative technology.”

Despite these challenges, long-term benefits often outweigh initial investments. Reduced material waste, faster prototyping, and the ability to create complex parts can lead to significant cost savings over time. However, carefully assess production needs and budgets before committing to the technology.

Material and Process Limitations

Metal 3D printing offers exceptional capabilities but comes with material and process limitations. Not all metals are compatible with every 3D printing method. For example, while technologies like Laser Powder Bed Fusion (LPBF) excel with titanium and aluminum, they may struggle with certain high-temperature alloys. Each material requires specific printing parameters, such as precise temperature control and laser power, complicating the process.

A part’s mechanical properties also vary based on material and method. While metal 3D printing can produce fully dense components, achieving consistent chemical properties remains a challenge. Some parts may exhibit anisotropic behavior, where strength varies with build direction, requiring careful design and part orientation to optimize performance.

“Material compatibility and process variability demand meticulous planning and expertise for successful metal 3D printing outcomes.”

Thermal management is another critical factor. The layer-by-layer structure generates significant thermal stress, potentially causing warping or cracking. Consider these stresses during design and use post-processing techniques like heat treatment to mitigate them. Additionally, support structures needed during printing to stabilize parts increase material use and post-processing time.

Post-Processing Requirements

Post-processing is a vital but time-consuming aspect of metal 3D printing. After printing, parts often need additional steps to meet quality and functional standards, including removing support structures, heat treatment, surface finishing, and dimensional inspection—each requiring specialized equipment and skilled labor, increasing overall production time and cost.

Removing support structures is particularly challenging for complex designs, requiring careful removal without damaging the part—a labor-intensive process. Heat treatment is another critical step, relieving residual stresses and enhancing a part’s mechanical properties. For aerospace and automotive applications, this step ensures components withstand extreme conditions.

Surface finishing improves a part’s appearance and function. The raw surface of 3D printed metal components is often rough due to the layer-by-layer structure, requiring techniques like polishing, sanding, or blasting for a smooth surface. In some cases, additional coatings or treatments may be needed to enhance corrosion resistance or meet aesthetic requirements.

“Post-processing transforms raw 3D printed parts into high-quality components but significantly impacts production time and cost.”

Dimensional inspection ensures final parts meet design specifications, using advanced tools like Coordinate Measuring Machines (CMM) or laser scanners—critical for industries like aerospace, where minor deviations affect performance.

Scalability for Mass Production

Metal 3D printing holds immense potential for manufacturing complex, high-performance parts, but scaling the technology for mass production presents unique challenges. To achieve scalability, address factors like production speed, material efficiency, and cost-effectiveness.

A primary obstacle to scaling metal 3D printing is production speed. Traditional manufacturing methods like casting or machining can produce large quantities of parts in less time, while metal 3D printing requires layer-by-layer construction, which can be time-consuming. Material choice also affects print duration, as some metals need specific parameters—such as precise temperature control and slower printing speeds—to ensure quality. Optimizing these parameters is crucial for increasing throughput without compromising part integrity.

“Material compatibility and printing parameters play a key role in determining the efficiency of mass production with metal 3D printing.”

Another challenge is managing support structures. These temporary elements stabilize parts during printing but increase material use and post-processing time. For mass production, minimizing support needs can significantly improve efficiency by designing self-supporting geometries or using advanced software to optimize part orientation, reducing waste and speeding the overall production process.

Material costs also impact scalability. High-quality metal powders like titanium or nickel-based alloys are expensive. While metal 3D printing minimizes waste by using only necessary material, initial raw material costs remain a barrier to mass adoption. Recycling unused powder and exploring alternative materials can help reduce costs and make mass production more feasible.

To scale effectively, consider integrating automation. Automated systems for material handling, part removal, and post-processing can streamline workflows and reduce labor costs. For example, robotic arms can remove printed parts from build platforms, and automated polishing machines can handle surface finishing. These advancements not only improve efficiency but also ensure consistency in high-volume production.

“Automation and process optimization are key to unlocking the full potential of metal 3D printing for mass production.”

Despite challenges, scalability in metal 3D printing is advancing. Innovations in multi-laser systems and faster printing technologies are reducing build times. Additionally, hybrid manufacturing methods combining 3D printing with traditional techniques offer practical solutions for scaling production. For example, use 3D printing to create complex features and traditional machining for simpler sections, balancing speed and complexity.

By addressing these factors, you can leverage metal 3D printing’s power for mass production, bringing huge promise to industries seeking to manufacture high-quality, customized parts at scale. As technology evolves, metal 3D printing is poised to become a cornerstone of modern manufacturing.

Conclusion

Metal 3D printing empowers creation of complex, customized parts with unmatched precision and efficiency. Advanced technologies like Direct Metal Laser Melting (DMLM) and Binder Jetting make once-impossible designs feasible. This additive manufacturing process uses only the metal needed for final components, significantly reducing material waste and offering a more sustainable alternative to traditional manufacturing.

While challenges like high costs and scalability persist, advantages such as faster prototyping, design flexibility, and waste reduction position 3D printed metal as a transformative force across industries.

For more information, please contact Debaolong Seiko.