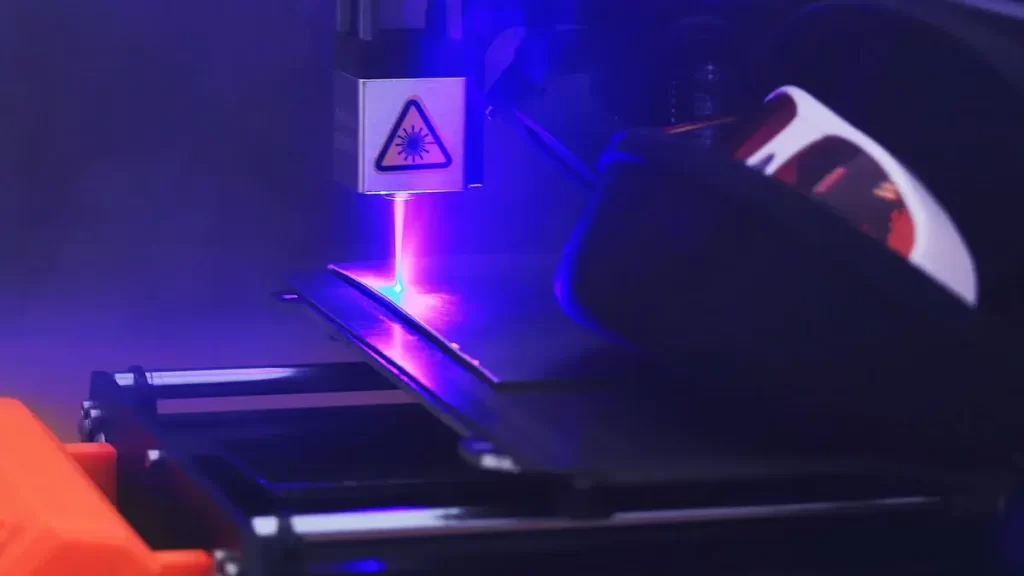

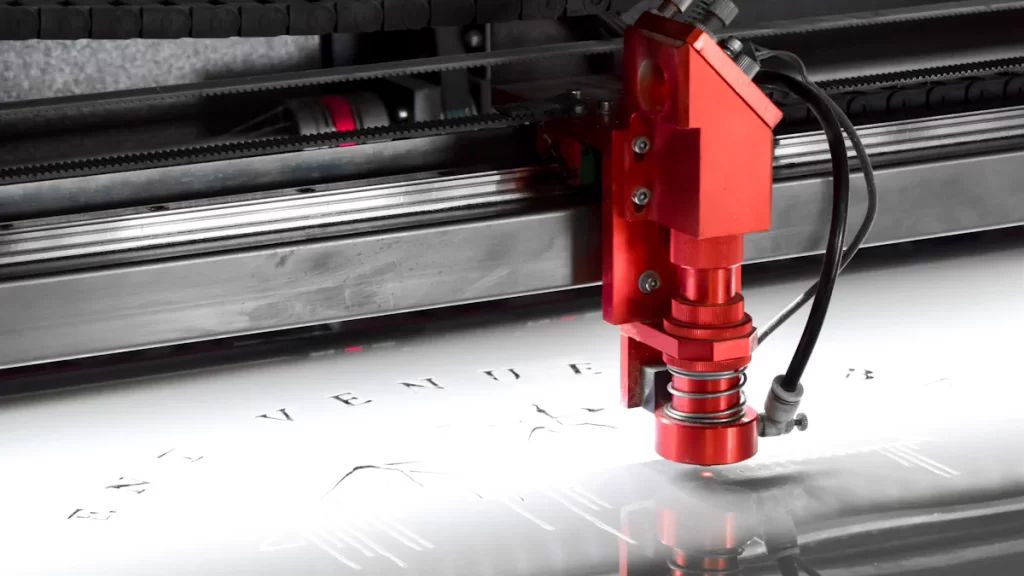

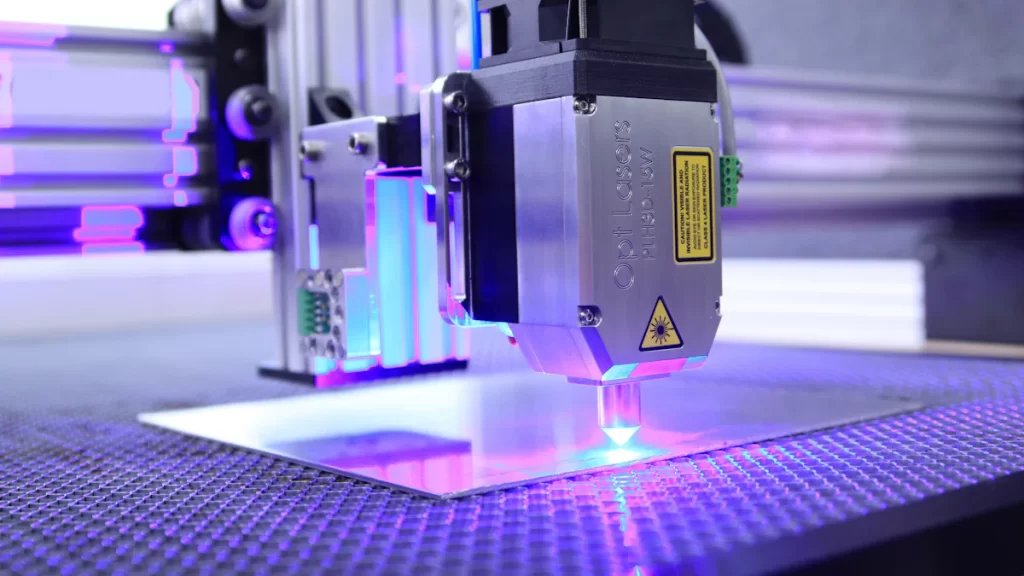

Laser cutting technology has revolutionized the metal manufacturing industry by delivering unparalleled precision, efficiency, and adaptability. Unlike traditional techniques, laser cutting melts materials rather than physically cutting them, producing smooth, flawless edges that eliminate the need for secondary finishing processes. This innovative approach effortlessly handles complex designs and intricate geometries, ensuring consistent results across diverse projects. Additionally, metal cutting laser systems significantly reduce material waste and enhance energy efficiency, establishing them as an eco-friendly choice for modern manufacturing. These attributes solidify laser cutting as the premier method for achieving excellence in metal fabrication.

Key Points

- Laser cutting offers unmatched precision with tolerances as low as 0.001 inches, making it ideal for industries requiring strict accuracy.

- The non-contact nature of laser cutting eliminates tool wear, ensuring consistent quality and reducing long-term maintenance costs.

- Laser cutting optimizes material usage by allowing tight nesting of parts, minimizing waste and driving cost savings.

- Advanced automation enables laser cutting systems to operate continuously, reducing labor costs and boosting productivity.

- The technology is versatile, capable of cutting diverse materials—from metals to plastics—meeting varied manufacturing needs.

- Laser cutting enhances product durability by creating clean edges that improve structural integrity, eliminating the need for secondary finishing.

- Adopting laser cutting helps businesses achieve faster production cycles and lower operational costs while maintaining high-quality standards.

The High Precision and Accuracy of Metal Cutting Lasers

How Laser Cutting Achieves Precision

Laser cutting achieves exceptional precision by using a focused laser beam to melt, burn, or vaporize materials. The process ensures clean, contact-free cuts, minimizing the risk of material deformation. Lasers enable precise manipulation, allowing them to tackle complex designs and intricate geometries that traditional methods struggle to handle. Advanced software controls the laser’s movement, ensuring consistent results across multiple production runs. This precision makes metal cutting lasers ideal for industries with strict tolerance requirements, such as aerospace, automotive, and electronics manufacturing.

The non-contact nature of laser cutting eliminates the need for mechanical tools, which wear over time and compromise precision. Additionally, the laser’s high energy density allows it to cut through metals of various thicknesses while maintaining sharp edges and smooth surfaces. This level of precision not only enhances product quality but also minimizes the need for secondary processing, saving time and resources.

Comparison with Traditional Cutting Methods

Traditional cutting methods like mechanical sawing or plasma cutting often fall short in precision and efficiency. Mechanical tools rely on physical force, leading to uneven cuts, material deformation, and increased equipment wear. While plasma cutting is faster than mechanical methods, it struggles to match the fine details and clean edges of laser cutting. These methods also generate more heat, potentially causing thermal damage to materials.

Laser cutting offers distinct advantages:

- Unrivaled Precision: Laser cutting achieves tolerances as low as 0.001 inches—difficult to replicate with traditional tools.

- Clean Edges: The focused laser heat source produces smooth, burr-free edges, eliminating the need for additional finishing.

- Material Efficiency: Tight nesting of parts optimizes material usage, minimizing waste.

- Versatility: Laser cutting handles various materials and thicknesses, from thin sheets to thick metal plates.

“Laser cutting offers extremely high precision, shorter lead times, reduced waste, lower costs, and the ability to handle complex jobs with tight tolerances.”

By combining speed, accuracy, and efficiency, laser cutting outperforms traditional methods, providing a reliable solution for high-quality production.

The Speed and Efficiency of Laser Cutting Technology

Faster Cutting Times

Laser cutting significantly reduces processing time compared to traditional methods. The focused laser beam cuts materials at high speeds with remarkable efficiency. For materials thinner than 25.4 mm, laser cutters deliver faster and more precise results than conventional tools. This speed is invaluable for industries with rapid production cycles, such as automotive and aerospace manufacturing.

Shorter cutting times offset the higher energy consumption of laser cutters. While these machines consume more energy per unit time, their ability to complete tasks faster results in net energy efficiency. This combination of speed and precision makes laser cutting ideal for projects with tight deadlines or high-volume demands.

“Laser cutting ensures precise, clean cuts without the costs or time associated with traditional methods.”

Minimizing cutting time allows businesses to streamline operations and meet strict schedules without compromising quality.

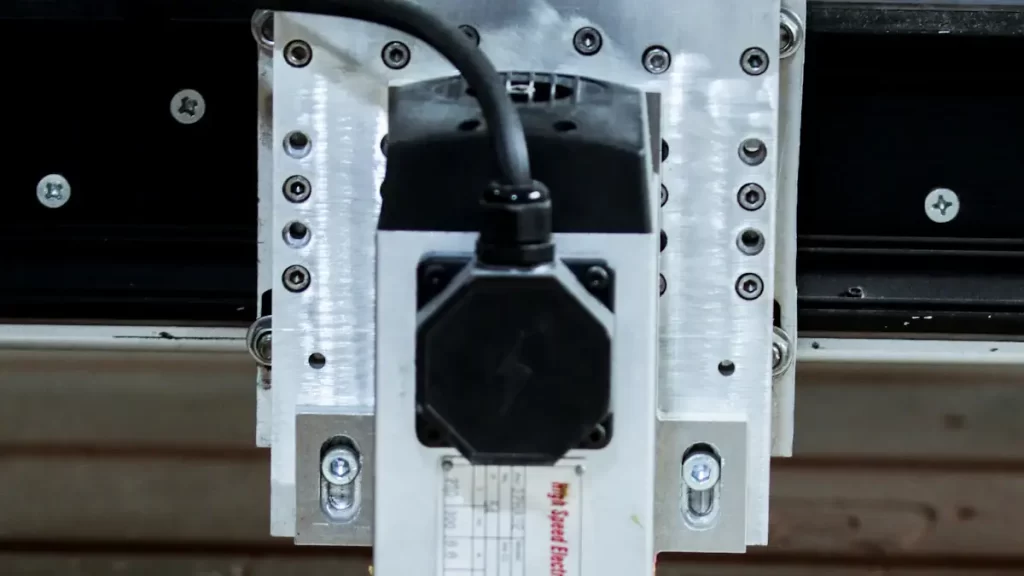

Automation Features

Modern laser cutting systems integrate advanced automation to enhance efficiency. Automatic laser cutters operate continuously with minimal human intervention, reducing labor costs and boosting productivity. These systems use programmable software to input designs and specifications, ensuring consistent results across multiple runs.

Automation enables laser cutters to handle complex tasks effortlessly. Intricate patterns, custom designs, and detailed geometries can be programmed directly into the system, eliminating manual adjustments. This saves time and reduces error risks, ensuring high-quality outcomes.

Automated systems also optimize material usage by tightly nesting parts, minimizing waste and maximizing yield from each metal sheet. Industries like manufacturing and electronics benefit significantly from these advancements, which require large-scale precision and efficiency.

The Cost-Effectiveness of Metal Cutting Lasers

Reduced Labor Costs

Laser cutting reduces labor costs by automating most manufacturing processes. Unlike traditional methods that require skilled operators to manually guide tools, laser cutting relies on advanced software and automation. Operators input designs and specifications, allowing the machine to perform precise cuts with minimal intervention. This reduces the need for specialized training, lowering overall labor expenses.

Automatic laser cutters can run continuously—even after hours—maximizing productivity without increasing labor costs. Businesses benefit from rapid project completion while maintaining consistent quality. By minimizing reliance on manual labor, laser cutting reduces human error risks, ensuring accurate results.

“Laser cutters handle high-volume projects at speed with perfect precision, reducing error costs and accelerating project delivery.”

This combination of automation and precision makes laser cutting a cost-effective choice for industries optimizing production.

Reduced Maintenance and Material Waste

Laser cutting systems require less maintenance than traditional cutting tools. Mechanical methods involve physical contact with materials, causing blade wear and frequent replacements. In contrast, laser cutting’s non-contact approach eliminates direct material interaction, reducing equipment damage risks and extending machine lifespan.

Laser cutting also excels in minimizing material waste. Traditional methods often generate excess waste due to inefficient cutting patterns and technical imprecision. Laser cutting allows tight nesting of parts on material sheets, maximizing utilization and reducing scrap. Precise cuts eliminate the need for secondary finishing, further saving resources.

Key advantages of laser cutting:

- Non-contact cutting reduces equipment wear and maintenance costs.

- Precise part nesting optimizes material usage and minimizes waste.

- Flawless edge finishes eliminate the need for additional processing.

“Compared to traditional methods, laser cutting enables precise, complex cuts that minimize material loss and improve utilization.”

The Versatility of Cutting Lasers for Metal Manufacturing

Ability to Handle Diverse Materials

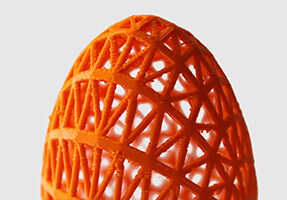

Laser cutting demonstrates exceptional versatility by adapting to various materials. From metals like steel, aluminum, and copper to non-metals like plastics, wood, ceramics, and fabrics, laser cutters seamlessly meet diverse manufacturing needs. This adaptability stems from the ability to adjust laser power and focus based on material properties—higher power for thick metal sheets, lower power for delicate materials like thin plastics or textiles.

Laser cutting precision ensures clean edges and smooth surfaces regardless of material, eliminating the need for extra finishing. Industries like automotive, aerospace, and electronics benefit from this flexibility, as they often require components from varied materials.

“Laser cutters offer high precision, speed, and flexibility, enabling easy cutting of diverse materials.”

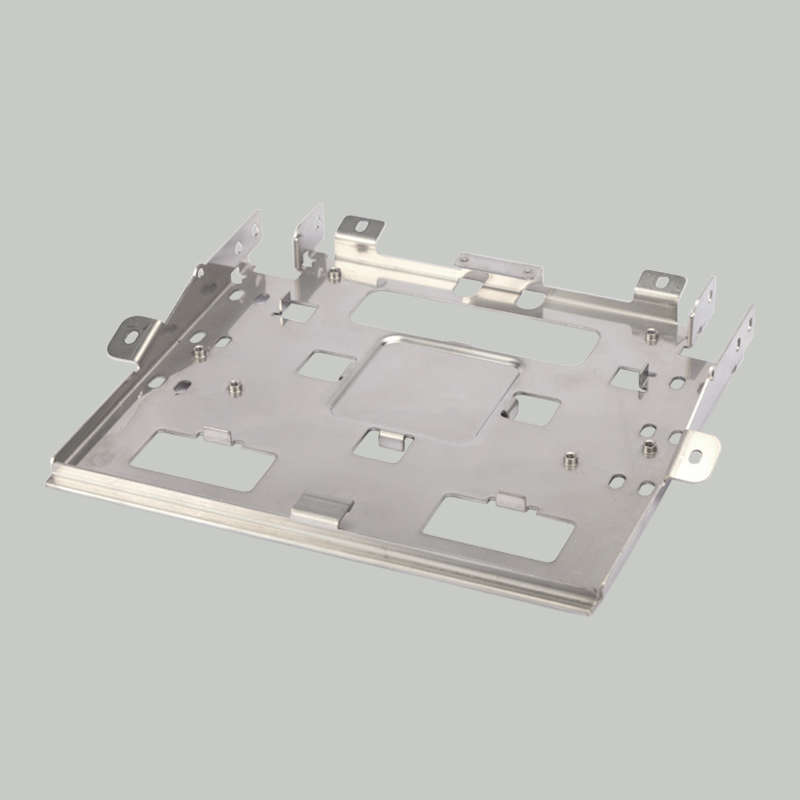

Complex and Custom Designs

Laser cutting excels in creating complex and custom designs that traditional methods struggle to achieve. The focused laser beam executes precise cuts with intricate details, making it ideal for complex geometries and patterns. Advanced software integration allows operators to input detailed designs, which the machine replicates with unmatched precision—valuable for industries like jewelry, architecture, and industrial manufacturing that require unique components.

The non-contact nature of laser cutting preserves the integrity of fragile materials. Additionally, the technology supports rapid prototyping, enabling businesses to test and refine designs quickly. This fosters innovation and reduces production cycles.

Key advantages for custom designs:

- High precision for intricate patterns.

- Consistent quality across multiple production runs.

- Ability to replicate complex geometries with minimal error.

The Quality and Reliability of Metal Cutting Lasers

Consistent Results

Laser cutting ensures consistent results through precise, repeatable cuts across multiple production runs. Advanced software integrated into laser systems allows operators to program exact specifications, ensuring every cut meets the same high standards. This consistency is vital for industries like aerospace and automotive, where uniformity impacts safety and performance.

The non-contact nature of laser cutting eliminates physical tool wear, which causes variations in traditional methods. Relying on a focused laser beam, the process maintains precision over time. The ability to handle complex designs and tight tolerances ensures even the most intricate components are produced with identical precision.

“Laser cutting guarantees shorter lead times, reduced waste, and the ability to handle the most complex jobs with unmatched precision.”

Enhanced Product Durability

Laser cutting improves product durability by producing clean, smooth edges that eliminate the need for secondary finishing. Traditional methods often leave burrs or rough edges that compromise material structural integrity. Laser cutting melts materials to form flawless edges, enhancing the overall strength and lifespan of final products.

Laser cutting precision also minimizes thermal damage to materials. Excessive heat from traditional methods can alter metal properties, causing warping or reduced durability. The focused heat application of laser cutting preserves original material characteristics, making it ideal for high-performance applications in aerospace and electronics.

The Environmental Benefits of Laser Cutting Technology

Energy Efficiency

Laser cutting technology offers significant energy efficiency in modern manufacturing. By focusing high-energy laser beams directly on materials, it minimizes energy loss during cutting. Unlike traditional methods relying on mechanical tools or excessive heat, laser cutting uses concentrated energy to achieve precise results with minimal waste. This targeted approach saves energy and reduces the overall carbon footprint of manufacturing projects.

Manufacturers can further enhance energy efficiency by integrating renewable energy sources into operations. Solar panels or wind turbines can power laser cutting systems, reducing reliance on fossil fuels. Advances in laser technology have also led to machines that consume less power while maintaining high performance, allowing businesses to optimize energy use without sacrificing productivity.

“Laser cutting helps reduce carbon emissions and conserve energy, making it a sustainable choice for modern manufacturing.”

Reduced Waste

Laser cutting excels in minimizing material waste, a key factor in eco-friendly manufacturing. Traditional cutting methods often generate significant scrap due to technical imprecision and inefficient cutting patterns. Laser cutting systems use advanced software to tightly nest parts on material sheets, maximizing utilization and reducing leftover waste.

The precision of laser cutting eliminates the need for secondary finishing processes like sanding or grinding, which typically generate additional waste. The cutting process directly produces smooth, burr-free edges, saving resources and reducing environmental impact. The non-contact nature of laser cutting also prevents damage to surrounding materials, ensuring every sheet is used efficiently.

Conclusion

Laser cutting stands as the ultimate choice for metal manufacturing due to its unmatched precision, speed, and cost-effectiveness. It effortlessly handles complex designs and geometries, ensuring high-quality results while minimizing material waste. Unlike traditional methods, laser cutting eliminates the need for secondary finishing, saving time and resources. Its versatility and ability to deliver consistent results make it a reliable solution for modern manufacturing. Businesses seeking efficiency and excellence should adopt metal cutting laser technology to optimize production processes and achieve outstanding outcomes.

For more information, please contact Debaolong Seiko.