Choosing between wire cutting and laser cutting can be tricky. This article details their similarities and differences to help you make a better decision.

How Does Wire Cutting Work?

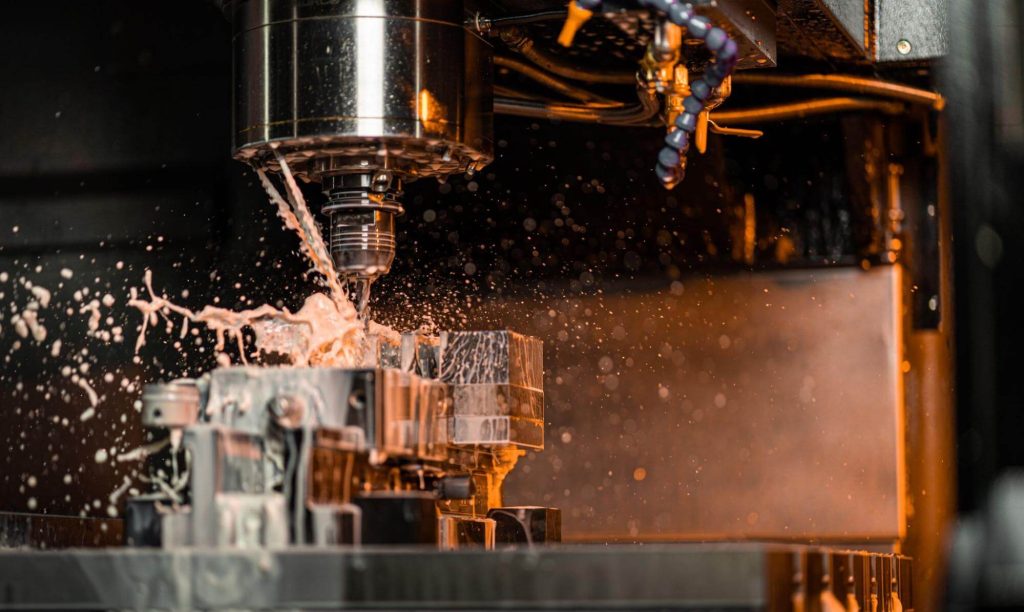

Also known as wire electrical discharge machining (Wire EDM), wire cutting uses a thin, charged metal wire to cut materials—typically metals. The wire is guided along a pre-set path, and materials are precisely melted through electrical discharge. This process occurs in a dielectric fluid, which cools the workpiece and clears debris during cutting.

This method is widely recognized for its ability to cut complex shapes with high precision, especially suitable for materials hard to machine with traditional methods, such as hardened steel. However, wire cutting is relatively slow compared to other cutting methods and works best for thinner materials.

What Is Laser Cutting Technology?

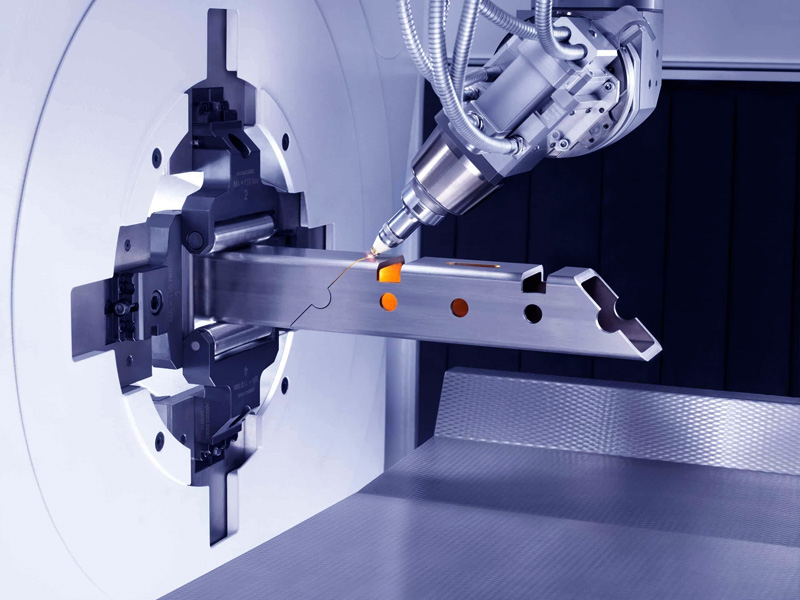

Laser cutting uses a highly concentrated laser beam to precisely cut or etch materials. The material melts or evaporates under the laser’s extreme heat, resulting in clean incisions. A Computer Numerical Control (CNC) system manages the process, enabling intricate designs and complex shapes with minimal manual assistance.

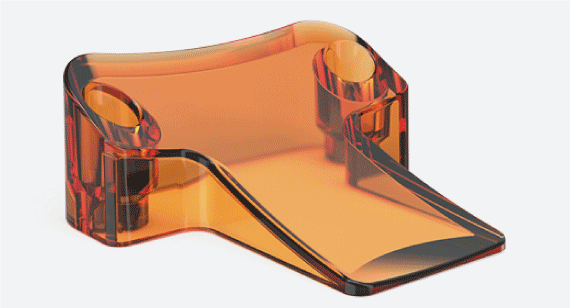

Thanks to its versatility, laser cutting works on various materials, including wood, polymers, metals, and more. Renowned for its accuracy and speed, it suits both small-scale and large-scale production. The technology delivers neat, precise results by reducing the need for extra polishing and providing smooth edges.

Wire Cutting vs. Laser Cutting: Key Differences

The two most commonly used technologies for precision cutting are wire cutting and laser cutting. Understanding their differences is crucial for selecting the right method for your project.

Cutting Method

- Wire Cutting: Uses a thin charged metal wire to cut materials by discharging electricity along the wire, ensuring high precision.

- Laser Cutting: Employs a focused laser beam to melt, evaporate, or burn through materials. The laser beam’s extreme heat enables accurate cutting, especially in lightweight materials.

Precision and Accuracy

- Wire cutting is renowned for its exceptional precision, especially with complex details. It excels at creating intricate shapes in hard metals like steel.

- Laser cutting is also highly precise but specializes in cutting thin materials with smooth edges. It’s often the preferred choice for fine, detailed cuts on delicate surfaces.

Cutting Speed

- Wire cutting is slower than laser cutting, making it suitable for smaller, more intricate projects or thicker materials.

- Laser cutting is faster, ideal for mass production or large projects. It can quickly cut various materials, making it perfect for high-volume work.

Material Suitability

- Wire cutting is best for cutting metals, especially thick or hard materials that are difficult to process with traditional methods. It’s ideal for precision machining of materials like tool steel and titanium.

- Laser cutting is versatile, handling various materials such as metals, plastics, wood, and acrylic.

Edge Quality

- Wire cutting typically leaves rougher edges that may require additional finishing.

- Laser cutting provides clean, smooth edges, reducing the need for further processing. This makes it ideal for projects where aesthetics and edge quality matter.

Cost and Maintenance

- Wire cutting machines usually have lower operating costs, especially for smaller, complex projects. However, they require regular maintenance to keep the wire and other components in good condition.

- Laser cutting machines have higher initial costs but are more cost-effective in mass production due to their speed and efficiency.

Applications of Wire Cutting and Laser Cutting

Each technology offers unique advantages, making them suitable for specific industries and materials.

Applications of Wire Cutting

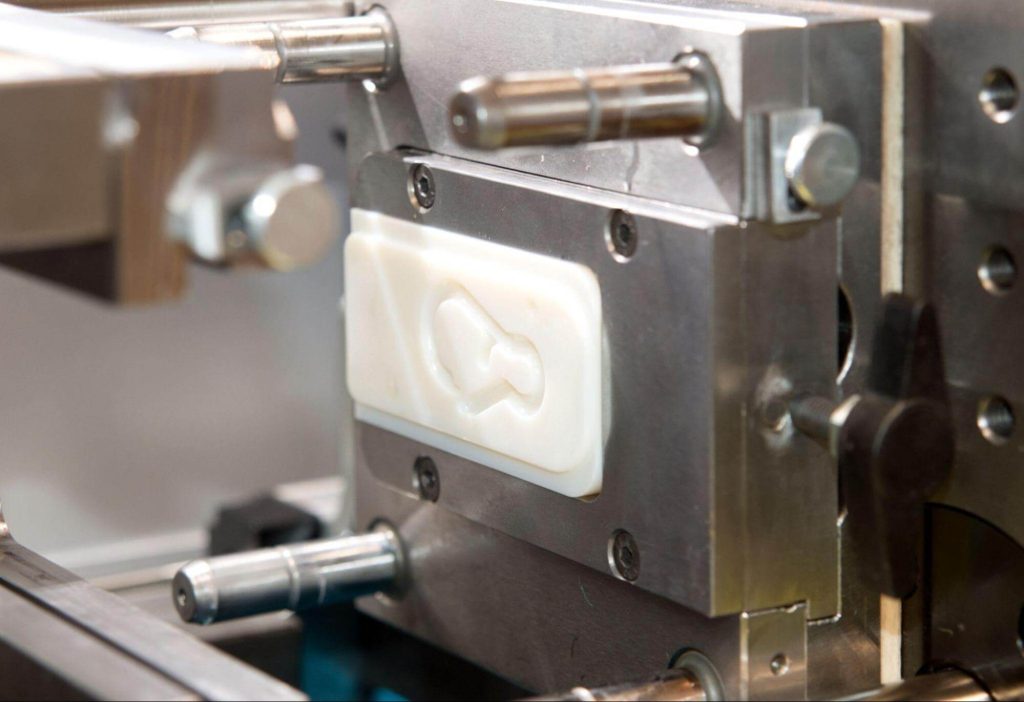

- Widely used in manufacturing molds, dies, and precision tools, ideal for cutting hard materials like tool steel, titanium, and other alloys.

- Enables complex details in very small components (e.g., aerospace parts) while minimizing deformation.

- Cuts specialized medical equipment and components requiring high precision, such as surgical instruments or implants.

- Creates complex shapes and fine details for mechanical parts, commonly used in industrial machinery.

Applications of Laser Cutting

- Perfect for creating detailed decorative patterns on materials like wood, acrylic, and metal, often used in signage and custom designs.

- Widely applied in the metalworking industry to cut thin metals like stainless steel, aluminum, and copper into precise shapes and sizes.

- Suits rapid prototyping and small-batch production in industries like electronics and fashion.

- Extensively used in woodworking to create complex patterns or fine carvings on wood and plywood.

Advantages and Disadvantages

Both wire cutting and laser cutting have their strengths and limitations, depending on project requirements.

| Wire Cutting | Laser Cutting |

|---|---|

| Highly accurate, especially for complex details | Excellent precision, particularly on thin materials |

| Slower than laser cutting | Faster, suitable for mass production |

| Best for hard metals and thicker materials | Versatile, works on metals, plastics, wood, etc. |

| Rougher edges may require extra finishing | Provides smooth, clean edges with minimal finishing |

| Typically lower cost for smaller projects | Higher initial cost but more efficient for large-scale production |

| Ideal for complex, detailed cuts | Suits simple and complex designs alike |

| Requires regular maintenance and wire replacement | Needs less maintenance but has higher initial costs |

| Mainly used for metals and hard materials | Extremely versatile, handles a wide range of materials |

How to Choose the Right Cutting Method for Your Project

Selecting the appropriate cutting method significantly impacts production quality, speed, and cost-effectiveness. Here’s how to decide based on your specific needs.

Consider Material Type

The material you use plays a key role in determining the best cutting method.

- Wire Cutting: Perfect for hard metals like tool steel, titanium, and alloys that are difficult to process with traditional methods.

- Laser Cutting: Versatile, suitable for cutting various materials—metals, plastics, acrylic, and wood—especially thin to medium-thickness materials.

Design Precision and Complexity

If your project involves complex or detailed cuts, precision is key.

- Wire Cutting: Offers exceptional precision for intricate shapes, making it ideal for complex designs, especially in hard materials.

- Laser Cutting: Also provides excellent precision but excels in projects requiring clean, sharp edges on lower-density materials.

Cutting Speed and Volume

Consider how quickly you need to complete the project and whether you’re handling large quantities.

- Wire Cutting: Though precise, it’s slower, suitable for small, one-off projects or low-volume production.

- Laser Cutting: Faster than wire cutting, perfect for high-volume, quick-turnaround production—an excellent choice for efficiency-focused businesses.

Cost and Budget

Your budget should also influence your decision.

- Wire Cutting: Usually has lower costs for small-scale operations or projects, but maintenance expenses can increase over time.

- Laser Cutting: Requires a higher initial investment but saves costs in the long run due to its speed and versatility, especially in mass production.

Maintenance: Wire Cutting vs. Laser Cutting

Both wire cutting and laser cutting require regular maintenance to ensure efficiency and longevity, but their maintenance needs differ due to underlying technologies and uses.

Wire Cutting Maintenance

Wire cutting machines need more frequent maintenance due to the nature of the wire and electrical components.

- Wire Replacement: The wire, which wears out during cutting—especially with hard materials—must be replaced regularly. Wire quality also affects cutting precision.

- Cleaning and Calibration: The machine’s wire guides and electrical components must be regularly cleaned and calibrated for smooth operation. Dirt, debris, or misalignment can impact cutting quality.

- Cooling System: Wire cutters have a cooling system to maintain wire temperature, which requires regular maintenance to avoid overheating and sustain cutting performance.

Laser Cutting Maintenance

Laser cutting machines are more autonomous and require less frequent maintenance, but like any machine, they need periodic attention.

- Laser Beam Alignment: Prolonged use may cause lens misalignment. Regular calibration and realignment ensure optimal performance.

- Lens and Mirror Cleaning: The lenses and mirrors that focus the laser beam should be cleaned regularly to prevent contaminants from obstructing the beam and affecting cutting.

- Cooling System: Regularly check the cooling system to keep the laser at near-ambient temperature, avoiding overheating and ensuring efficient operation.

- Software Updates: Since laser cutters integrate with computer software, updating them regularly ensures smooth operation and access to new features.

While both technologies need regular maintenance, wire cutting requires more manual intervention (e.g., wire replacement and cleaning), whereas laser cutting relies more on alignment, lens cleaning, and software updates—more automated but requiring detailed periodic checks.

For more information, please contact Debaolong Seiko.