In the ever-evolving landscape of manufacturing, the demand for precision and efficiency has never been greater. Among the services that stand out in meeting these needs is OEM steel plasma cutting. This advanced technology combines the precision of computer-controlled machinery with the power of plasma technology to cut steel with unmatched accuracy. In this blog post, we explore the world of OEM steel plasma cutting services, highlighting their advantages, applications, and why they are a game-changer for industries worldwide.

What is Plasma Cutting?

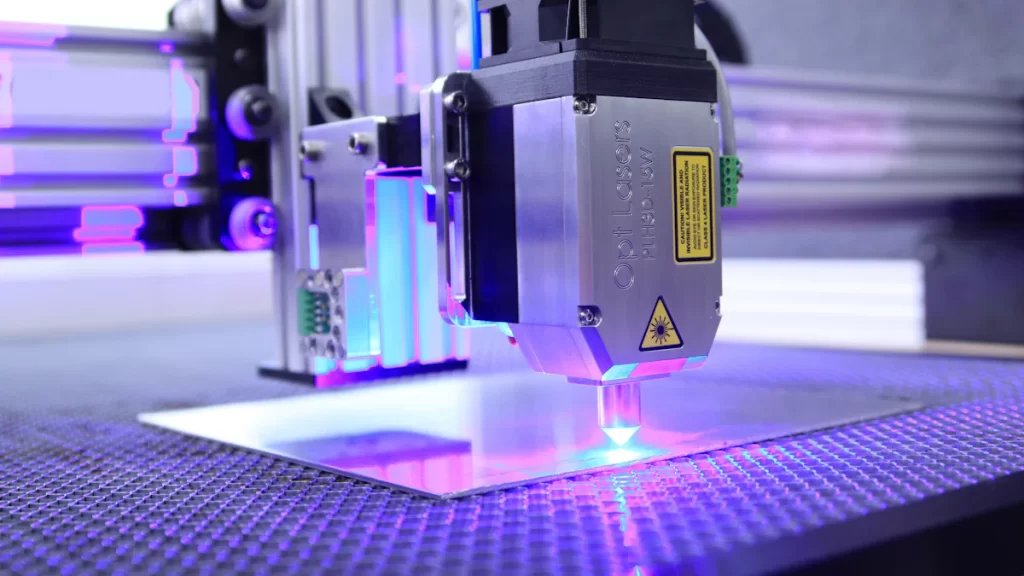

Plasma cutting is a process that uses a high-velocity jet of ionized gas (plasma) to melt and cut conductive materials like steel. Renowned for its speed and precision, this method is ideal for cutting complex shapes and intricate designs. Plasma cutting can handle various thicknesses, from thin sheets to heavy plates, offering versatility for numerous applications.

The Role of OEM in Plasma Cutting Services

OEM (Original Equipment Manufacturer) refers to companies that produce parts and equipment for use in products sold by other manufacturers. In the context of plasma cutting services, OEMs provide tailored solutions to meet the specific needs of different industries. These services go beyond mere steel cutting; they involve a comprehensive manufacturing approach, including design, production, and quality control.

Advantages of OEM Steel Plasma Cutting Services

Precision and Accuracy

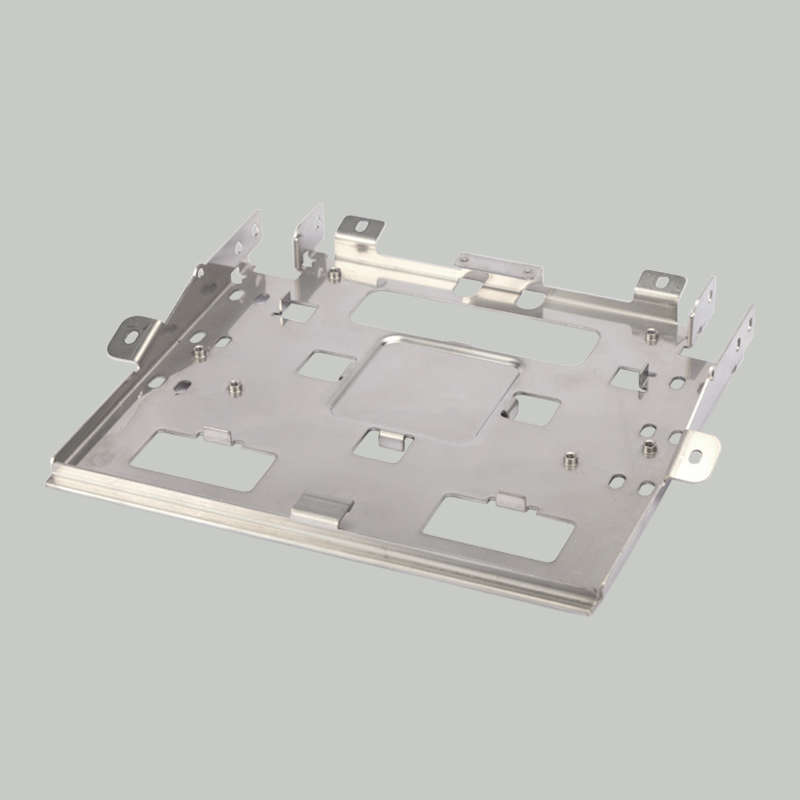

One of the most significant advantages of OEM steel plasma cutting services is the level of precision they offer. Modern plasma cutters, controlled by computers, enable extremely accurate cuts. This precision is critical in industries like aerospace, automotive, and construction, where even the smallest deviations can lead to major issues.

Speed and Efficiency

Plasma cutting is renowned for its speed. It can cut steel faster than traditional methods like sawing or drilling. This efficiency translates to shorter production times, allowing manufacturers to meet tight deadlines and enhance overall productivity.

Versatility

OEM steel plasma cutting services are highly versatile, capable of handling various types and thicknesses of steel. Whether you need to cut thin sheets for precision components or thick plates for heavy-duty applications, plasma cutting delivers. This adaptability makes it a popular choice across industries.

Cost-Effectiveness

While the initial investment in plasma cutting equipment can be high, the long-term benefits make it a cost-efficient solution. The speed and efficiency of plasma cutting reduce labor costs and minimize waste, leading to significant savings over time. Additionally, the precision of cuts reduces the need for secondary finishing processes, further lowering production costs.

Customization

OEM services are all about customization. They work closely with clients to understand their specific requirements and deliver tailored solutions that meet their needs. This customized approach ensures the final product adheres to the highest quality and performance standards.

Applications of OEM Steel Plasma Cutting Services

Automotive Industry

In the automotive sector, precision and reliability are paramount. OEM steel plasma cutting services are used to manufacture a wide range of components, from body panels to complex engine parts. The ability to produce intricate shapes with high precision ensures every component fits perfectly, enhancing overall vehicle performance and safety.

Aerospace Industry

The aerospace industry demands the highest level of precision and quality. OEM steel plasma cutting services provide the accuracy needed to manufacture components that meet strict aerospace standards, including everything from structural parts to complex elements used in aircraft engines.

Construction Industry

In construction, plasma cutting is used to fabricate structural steel components, beams, and supports. The speed and efficiency of plasma cutting allow construction projects to progress quickly, while precision ensures each component fits seamlessly.

Industrial Equipment

Industrial equipment manufacturers rely on OEM steel plasma cutting services to produce parts that are both durable and precise, including mechanical components, frames, and custom parts that require high accuracy and strength.

Why Choose OEM Steel Plasma Cutting Services?

Expertise and Experience

OEM providers bring a wealth of expertise and experience. They understand the complexities of different industries and can deliver solutions that meet specific requirements, ensuring the final product is of the highest quality.

State-of-the-Art Technology

OEM steel plasma cutting services leverage the latest technology to deliver exceptional results. Advanced machinery, computer control systems, and cutting-edge software ensure every cut is precise and efficient.

Quality Management

Quality control is a cornerstone of OEM services. Rigorous testing and inspection processes ensure each component meets the highest quality and performance standards—attention to detail that sets OEM services apart from standard manufacturing processes.

Conclusion

OEM steel plasma cutting services are revolutionizing manufacturing. With their precision, efficiency, and versatility, they offer a comprehensive solution for producing high-quality steel components. Whether in automotive, aerospace, construction, or industrial equipment, OEM steel plasma cutting services meet your needs with unmatched accuracy and reliability. Embrace the future of manufacturing and discover the benefits OEM steel plasma cutting services bring to your business.

For more information, please contact Debaolong Seiko.