Today, let’s delve into Kovar alloy—a material or alloy effectively used to address critical applications like thermal expansion issues. This article will provide high-quality insights into Kovar alloy, including its composition, applications, and various aspects of this fascinating material. First, let’s understand what Kovar alloy is:

Kovar Alloy

Kovar alloy, a gray-silver, vacuum-prepared iron-cobalt-nickel alloy, boasts 化学成分 (chemical composition) controlled within extremely narrow ranges, making it ideal for tackling thermal expansion and similar challenges. Its thermal expansion coefficient matches that of borosilicate glass.

Composition of Kovar Alloy

The chemical composition of any metal is crucial to determining its mechanical properties. Kovar alloy is first manufactured in a vacuum, with its composition strictly controlled within tight limits. Overall, Kovar is an iron-cobalt-nickel alloy, with the weight percentages of each element as follows:

| Element | Weight Percentage (%) | Role in the Alloy |

|---|---|---|

| Iron (Fe) | 54% | Base metal providing structural strength. |

| Nickel (Ni) | 29% | Controls thermal expansion to match glass/ceramic. |

| Cobalt (Co) | 17% | Enhances thermal stability and magnetic properties. |

| Manganese (Mn) | ≤0.50% | Improves machinability and deoxidization. |

| Silicon (Si) | ≤0.20% | Reduces oxidation during melting. |

| Carbon (C) | ≤0.02% | Minimizes brittleness. |

| Sulfur (S) | ≤0.02% | Prevents thermal cracking. |

The table above lists the roles of each alloying element. Kovar alloy excels in thermal expansion management primarily due to its nickel and cobalt content.

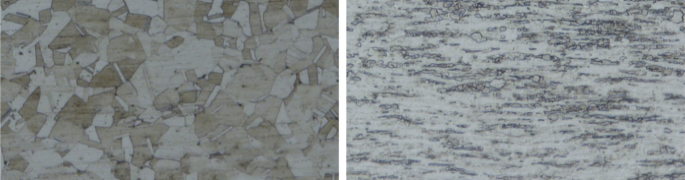

Microstructure of Kovar Alloy

Kovar material features a fine-grained microstructure, endowing it with strength and fatigue resistance—qualities essential for manufacturing precision components like RF packages. A micrograph of the microstructure is as follows:

Thermal Expansion Matching

As previously mentioned, Kovar alloy has a thermal expansion coefficient nearly identical to borosilicate glass, specifically 5.1–10 × 10⁻⁶/°C within the range of 30–200°C. This property prevents sealing failures in electrical enclosures.

Corrosion Resistance

Kovar alloy is typically suitable for high-temperature applications (below 400°C). Passivation or coating treatments can enable its use in harsh environments.

Why Engineers Choose Kovar Alloy for Machined Parts

Kovar alloy stands out due to its precisely controlled chemical composition and vacuum manufacturing process. Let’s explore why engineers specifically opt for this material:

- Sealing

The low thermal expansion characteristic of Kovar makes it suitable for glass-to-metal seals. For example, in high-pressure feedthrough applications of MRI machines, which require a leak rate of less than 1 × 10⁻⁸ atm·cc/s, Kovar’s thermal expansion coefficient (≈5.1 × 10⁻⁶/°C) prevents cracking under thermal cycling. - Magnetic Properties

Kovar alloy has a magnetic permeability of approximately 2,000 μᵣ, which can be further adjusted through heat treatment. It serves as a magnetic shield for MRI enclosures, exhibiting controllable permeability. - Temperature Stability

Kovar material maintains excellent dimensional stability even at high temperatures. Kovar seals are used in nuclear reactors, remaining intact in high-temperature and radiation environments.

Machinability Challenges of Kovar

Machining Kovar alloy can pose challenges for machine operators. Despite its superior thermal expansion properties, its machinability is poor, as discussed in this section:

- Work Hardening and Built-Up Edge (BUE)

When stressed, Kovar alloy undergoes work hardening, becoming harder. This leads to tool wear and BUE, causing two main defects:

- Poor surface finish

- Higher costs due to frequent tool changes

Solutions include using sharp carbide tools and avoiding dwell times.

- Diffusion Tool Wear

During Kovar machining, cobalt diffuses into the workpiece from the tool due to high temperatures, causing premature tool failure and increased machining time.

Diamond-coated tools are recommended for their diffusion resistance, along with lower machining speeds. - Coolant Selection

Inappropriate coolant use can lead to chip welding and tool damage, resulting in poor part tolerances and 报废 (scrap). High-pressure coolant can address this issue.

Kovar CNC Machining Processes

Due to its unique properties, Kovar alloy requires advanced machining techniques. Thus, we specialize in precision Kovar alloy CNC machining. Below are different CNC operations for Kovar:

- Precision Kovar Turning

Turning is suitable for cylindrical Kovar components, offering:

- Advantages:

- Achieves tight tolerances up to ±0.005 mm for cylindrical parts

- Excellent surface finish (up to 0.5 Ra)

- Cost-effective and high-yield for seals

- Disadvantages:

- Post-turning processes may be needed for complex part designs

- Sharp carbide tools are essential due to Kovar’s work-hardening nature

- 5-Axis Kovar Milling

5-axis machining allows precise processing of Kovar parts along five axes, ideal for complex designs:

- Advantages:

- Complex parts like aerospace enclosures can be machined in a single setup

- Maintains accuracy even at low radial depths (≤10% tool diameter), reducing chip welding

- Disadvantages:

- Expensive due to high machining and tool costs

- Requires advanced programming skills

- EDM and Wire EDM for Kovar

EDM is suitable for fine cutting of Kovar parts, especially hardened materials:

- Advantages:

- No mechanical stress, suitable for hard materials

- Processes complex cuts like microfluidic channels

- Disadvantages:

- Not suitable for high-volume production

- Higher energy consumption and electrode costs increase part prices

- Micro-Drilling Kovar

Drilling is used for medical and electronic components, achieving precision holes with tolerances <1 mm:

- Advantages:

- Enables high aspect ratios (e.g., 10:1 depth-to-diameter) with minimal deflection

- Critical for surgical instrument ports

- Disadvantages:

- Rapid tool wear increases maintenance costs

- Chip evacuation is difficult (peck drilling or high-pressure coolant can help)

Tips for Better Kovar Machining

Kovar is notoriously difficult to machine due to its hardening properties and abrasive surface. Careful attention is essential. Here are key parameters:

- Choose the Right Tools

Two common cutting tools are high-speed steel (HSS) and carbide:

| Factor | HSS Tools | Carbide Tools (Recommended) |

|---|---|---|

| Tool Life | 3–5x shorter | 5–10x longer than HSS |

| Cutting Speed | Limited to ≤60 m/min | Optimized at 80–200 m/min |

| Work Hardening | Higher (dull edges worsen hardening) | Lower (stays sharp longer) |

| Cost | Lower upfront ($10–$50/tool) | Higher ($50–$200/tool), but cost-effective long-term |

| Best For | Prototypes, small batches | Production runs, tight-tolerance parts |

| Coating | Seldom coated; poor heat resistance | TiAlN/AlCrN coatings reduce heat by 30% |

- Optimize Speed and Feed

Balanced speed and feed prevent work hardening and tool wear. For an annealed Kovar part with a Ø10 mm TiAlN-coated carbide end mill:

| Operation | Speed (m/min) | Feed (mm/tooth) | Cut Depth (mm) |

|---|---|---|---|

| Roughing | 80–100 | 0.08–0.12 | 1.5–2.0 |

| Finishing | 120–150 | 0.03–0.05 | 0.2–0.5 |

- High-Pressure Coolant

Kovar machining retains heat, so:

- Use high-pressure coolant (1000–1450 psi / 70–100 bar) at ≥15 L/min

- Use synthetic coolants to flush chips and reduce cutting zone temperature

Surface Treatments and Post-Processing Options

Post-processing enhances surface finish and corrosion resistance, improving durability:

- Electrochemical Polishing

An electrochemical process to remove surface defects:

- Mechanism: Immerse Kovar parts in an acidic electrolyte; direct current dissolves micro-cracks, smoothing the surface.

- Achieves a mirror-like finish (0.1–0.3 Ra).

- Nickel and Gold Plating

Adds functional layers to Kovar parts:

| Coating | Nickel Plating | Gold Plating |

|---|---|---|

| Primary Purpose | Wear resistance, solderability, EMI shielding | Oxidation resistance, high conductivity, RF performance |

| Process | Electroless or electroplating | Electroplating (requires nickel underlayer) |

| Typical Thickness | 5–25 μm | 0.5–3 μm (thinner to reduce cost) |

| Main Advantages | – Increases hardness (500–600 HV); – Corrosion barrier; – Lowers contact resistance; | – Prevents tarnishing; – Excellent high-frequency signal transmission; – Biocompatibility; |

| Cost Comparison | $0.50–$2.00 per dm² | $5–$20 per dm² (depends on gold price) |

| Best Applications | – Connector housings; – Shielding cans; – Industrial sensors; | – RF/microwave components; – Implantable medical devices; – High-reliability aerospace connectors; |

- Vacuum Stress Relieving

A heat treatment to remove machining-induced stresses:

- Mechanism: Heat Kovar to 750°C (recrystallization temperature) under high vacuum (≤10⁻⁵ mbar) to prevent oxidation.

- Prevents deformation in thin-walled parts.

Dimensional Control and Metrology

For critical applications, precise dimensional accuracy is non-negotiable:

- Thin-Wall Tolerances: Achieve ±0.025 mm accuracy with slow, gentle finishing and no deflection.

- Non-Contact Metrology: Use white-light interferometry to check surface roughness <1 μm; employ CT scans for internal features.

- Helium Leak Testing: Detects tiny leaks (1×10⁻⁹ cc/s), essential for pressure-critical components.

Industrial Case Studies of Kovar Machined Parts

- Aerospace IMU Housings

Kovar machined parts are used in inertial measurement unit housings for aircraft and satellites, offering excellent thermal stability (-65°C to +150°C), magnetic shielding, and airtightness. - Medical Feedthroughs

Kovar machined parts are used in medical feedthroughs due to:

- Biocompatibility

- MRI compatibility

- Sealing reliability

- 5G RF Packages

Kovar parts serve in high-frequency RF modules for 5G base stations and radar systems, thanks to thermal expansion matching, stable signal integrity, and efficient thermal management.

Global Sourcing Tips for Kovar Machining

Consider factors like cost, quality, and lead time when purchasing Kovar machined parts:

- ASTM F15 Certification

Ensure Kovar material composition, traceability, and that suppliers follow ASTM F15 standards. - Local vs. Chinese Outsourcing

| Factor | Local (US/EU) | China |

|---|---|---|

| Cost | $120–$250/hour | $30–$80/hour |

| Lead Time | 2–4 weeks (prototype) | 4–8 weeks (including shipping) |

| Quality Control | Easier on-site inspection | Requires third-party QC (e.g., SGS) |

| Example Cost | 100 Kovar RF shields: $18,000 (US) | Same order: $6,500 (China) + $2,000 shipping |

- Vacuum Furnace Facilities

Prioritize suppliers with vacuum furnaces to prevent part oxidation.

Conclusion

Kovar alloy, a vacuum-melted material, is widely used in critical applications due to its low thermal expansion, temperature stability, and sealing properties. However, its work-hardening and abrasive nature demand highly skilled and precise machining.

For more information, contact Debaolong Seiko. Feel free to upload your designs to Debaolong Seiko for a quote.