What Are Bearings and Why Are They Critical?

Bearings are indispensable mechanical components that reduce friction, support loads, and constrain motion in one or more directions. Found in everything from wristwatches to massive forging presses, they enable rotation in parts like bicycle sprockets and car axles by converting sliding motion into rolling motion.

Primary Functions of Bearings

- Friction Reduction: Converting sliding to rolling motion, aided by lubricants, minimizes energy loss.

- Load Support: Handles radial and axial forces to maintain component alignment.

- Motion Control: Guides precise, uniform movement for consistent rotational speed.

How Bearings Minimize Friction

Smooth rolling elements (e.g., balls in ball bearings) and raceways, combined with lubricants, reduce the coefficient of friction. Rolling contact creates less resistance than sliding, ensuring efficient motion.

Benefits of Bearings in Mechanical Systems

- Energy Savings: Lower friction requires less power for operation.

- Uniform Speed: Consistent surface properties maintain steady rotational velocity.

- Extended Machine Life: Reduced wear from minimal contact and friction.

1. Ball Bearings: Types and Common Uses

Ball bearings feature spherical rolling elements for low friction and high speed, divided into subcategories:

Material Types

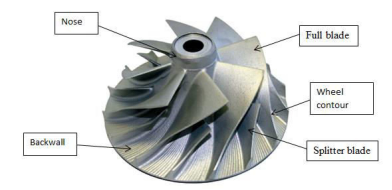

- Titanium Ball Bearings: Preferred in aerospace and medical devices for high strength-to-weight ratio, corrosion resistance, and fatigue durability—though costlier than steel.

Deep Groove Ball Bearings

- Housings: Pillow blocks (for conveyor shafts, fans) and flanged casings.

- Advantages: Handle radial and axial loads, suit high-speed applications like electric motors and pumps due to simple, robust design.

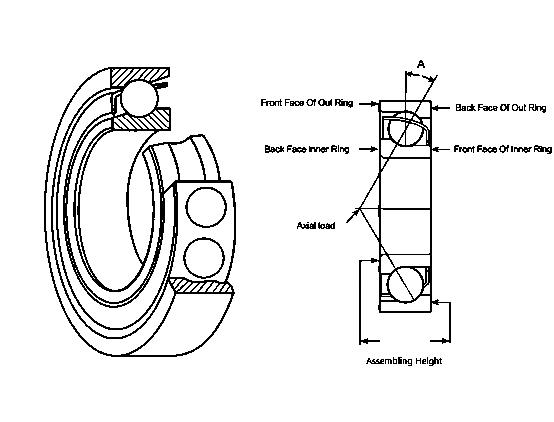

Angular Contact Ball Bearings

- Housings: Flanged and cartridge casings.

- Application: With contact angles of 15°–40°, they support combined loads in machine tool spindles, centrifugal pumps, and precision gearboxes.

Self-Aligning Ball Bearings

- Housings: Pillow blocks and self-aligning casings.

- Use: Auto-correct shaft misalignment in agricultural machinery, textile equipment, and conveyors.

Thrust Ball Bearings

- Housings: Thrust and washer-type casings.

- Function: Designed for axial loads in crane hooks, vertical shafts, machine tool tables, and elevator motors.

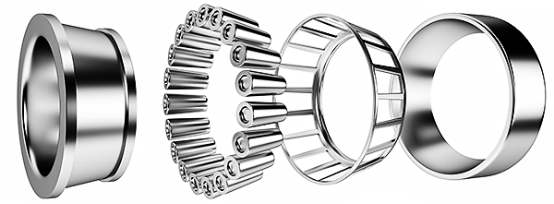

2. Roller Bearings: Types and Applications

Roller bearings use cylindrical or tapered elements for higher radial load capacity (line contact vs. ball bearings’ point contact):

Cylindrical Roller Bearings

- Housings: Insert, cartridge, and end cap casings.

- Advantages: Larger contact area enables high load capacity and stiffness, ideal for motors, machine tool spindles, and compressors.

Spherical Roller Bearings

- Housings: Split, self-aligning, and adapter sleeve casings.

- Use: Accommodate shaft misalignment and heavy loads in mining equipment, vibrating screens, and paper machinery.

Tapered Roller Bearings

- Housings: Flanged, double-cup, and combined casings.

- Why Preferred in Vehicles: Tapered geometry handles radial/axial loads in automotive axles and heavy machinery.

Needle Roller Bearings

- Housings: Stamped cup, cage, and insert casings.

- Application: Compact design suits space-constrained setups like gearboxes and agricultural tools.

3. Plain Bearings (Friction Bearings)

Simple bearings without rolling elements, using a sleeve for shaft rotation, often with lubrication:

Types Explained

- Journal Bearings: Support radial loads in engines and turbines.

- Sleeve Bearings: Basic tubular design for low-speed applications like fans.

- Flanged Bearings: Mounting flanges ensure alignment in conveyors.

| Journal Bearing | Sleeve Bearing | Flanged Bearing |

|---|---|---|

| Cylindrical | Tubular | Tubular with flange |

| Radial load | Light radial | Radial + limited axial |

| Split housing | Integrated | Flanged mounting |

| Additional axial support needed | None | Built-in flange |

| Engines, turbines | Fans, small motors | Conveyors, fixtures |

Advantages & Limitations

- Pros: Low cost, compact, tolerant of misalignment.

- Cons: High wear, low precision, high friction, unsuitable for high speeds.

- Applications: Industrial machinery, automotive components, consumer products.

4. Linear Bearings

Guide shafts in straight-line motion, reducing friction for precise alignment:

How They Work

Leverage lubricants and rolling elements (or sliding contact) to minimize friction in linear paths.

Types and Features

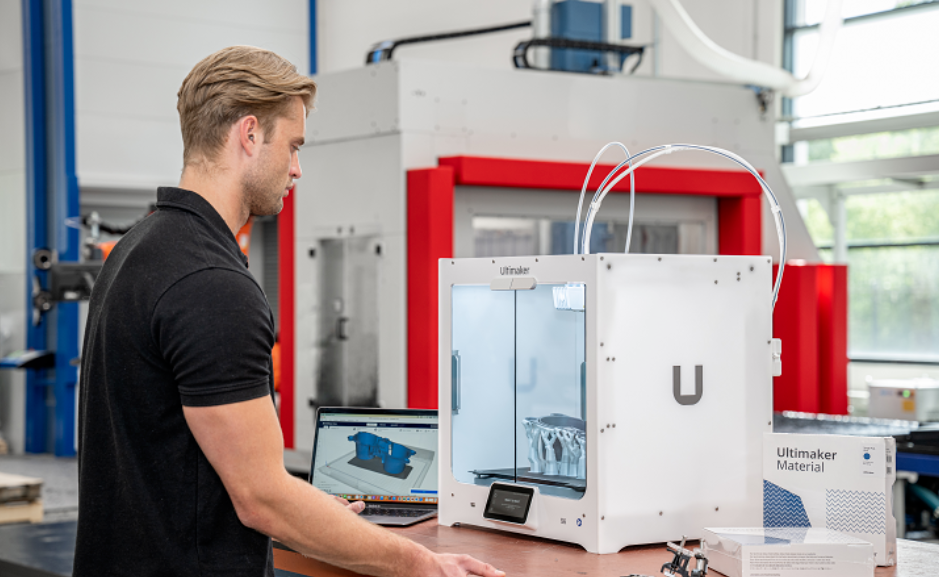

- Ball Bushings: Smooth motion with ball recirculation, ideal for CNC and 3D printers.

- Linear Roller Bearings: Higher load capacity for industrial robots and heavy machinery.

- Plain Linear Bearings: Self-lubricating materials for light-duty uses like furniture drawers.

| Type | Housing | Load Capacity | Precision | Friction | Applications |

|---|---|---|---|---|---|

| Ball Bushing | Flanged | Medium | High | Very low | CNC machines, 3D printers |

| Roller | Block | Heavy | Medium | Low | Industrial robots |

| Plain | Compact block | Light | Low | Medium | Furniture, light machinery |

5. Mounted Bearings

Pre-assembled with housings for easy installation, offering alignment and replacement convenience:

Types

- Pillow Block Bearings: Mount on flat surfaces for general machinery.

- Flanged Bearings: Bolt-on flanges for wall-mounted shafts.

- Take-Up Bearings: Adjustable for belt/chain tension in conveyor systems.

Selection Factors

Load magnitude, direction, space constraints, maintenance accessibility, and housing type.

Specialty Bearings: Fluid and Magnetic

- Fluid Bearings: Use pressurized fluid (hydrostatic) or shaft rotation (hydrodynamic) to levitate the shaft, enabling near-frictionless operation.

- Magnetic Bearings: Active (electromagnetic with feedback control) or passive (permanent magnets) for levitation in high-speed applications like turbines.

Bearings in Automotive Applications

- Wheel Bearings: Tapered roller bearings handle radial/axial loads from wheel motion.

- Transmission Bearings: Needle bearings for compact spaces; tapered rollers for shafts.

- Engine Bearings: High-temperature plain bearings for crankshafts and camshafts.

| System | Bearing Type | Function | Benefits |

|---|---|---|---|

| Engine | Journal/plain | Support crankshaft/camshaft | Reduce friction, handle heat |

| Transmission | Needle, ball, tapered roller | Support gears | Smooth shifting |

| Wheels | Deep groove ball/tapered roller | Enable rotation, carry load | Stable, safe operation |

| Steering | Ball/thrust | Assist steering motion | Responsive control |

| Suspension | Spherical roller/bushings | Absorb shocks, allow motion | Maintain alignment |

Impact on Vehicle Performance

High-quality bearings ensure smooth operation, reducing wear, improving fuel efficiency, and minimizing maintenance. Worn bearings signal noise, vibration, or reduced performance.

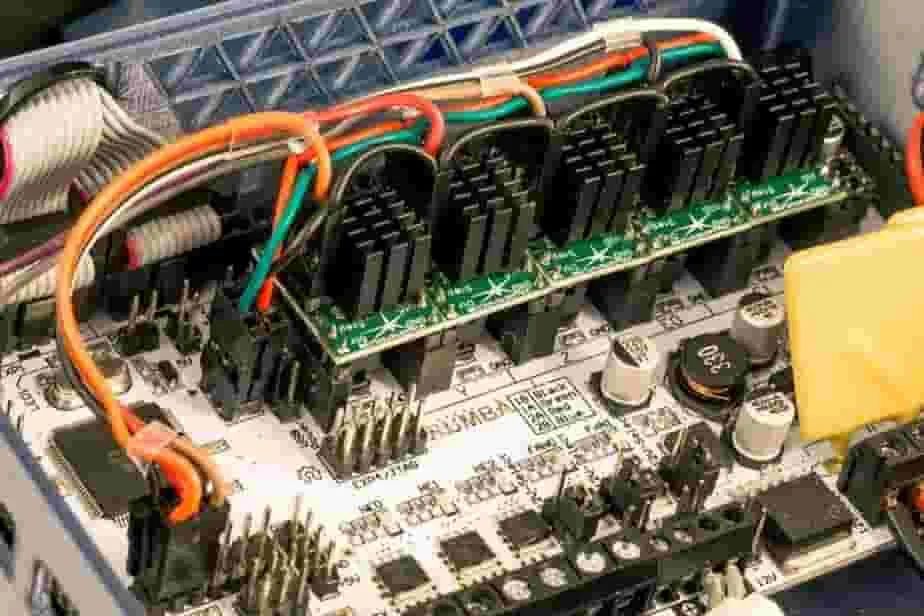

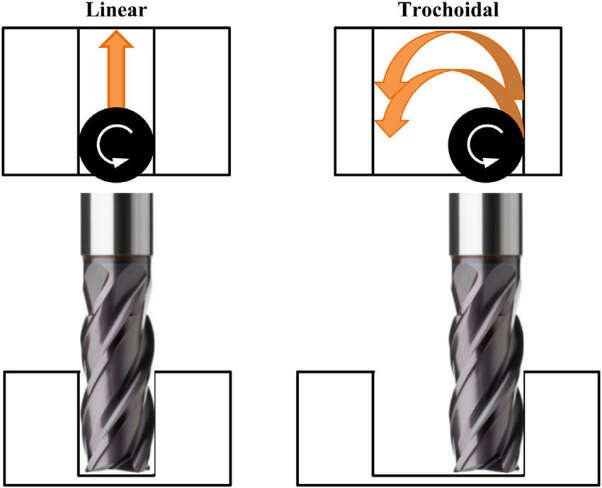

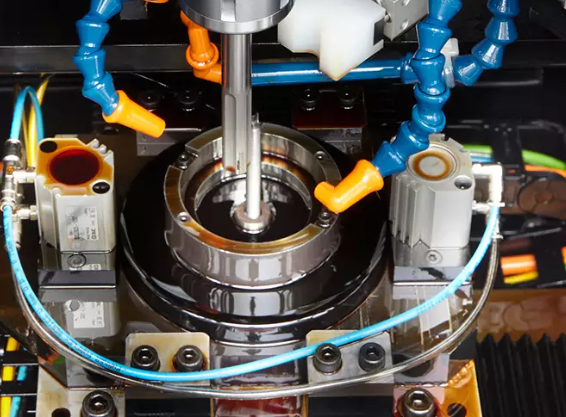

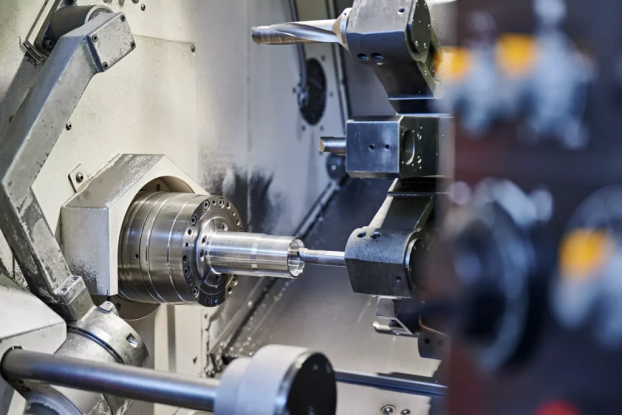

CNC Machining for Precision Bearings

- Process: CAD designs convert to CAM-generated G-code for CNC turning, milling, and grinding.

- Titanium Ball Bearing Steps: Material preparation, turning, heat treatment, raceway milling, drilling, grinding, inspection, assembly, and testing.

- Advantages: Customization per CAD specs, use of special alloys, added functional features, and cost-effective batch production.

Conclusion

With diverse types, materials, and designs, selecting the right bearing is critical for minimizing friction, optimizing energy efficiency, and extending machine life. Precision engineering—from material choice to CNC machining—ensures bearings meet the specific demands of any application, from automotive to aerospace. For custom bearing solutions, trust Debaolong Seiko’s expertise in precision manufacturing.

For more information, please contact us at Debaolong Seiko. You are also welcome to upload your designs to Debaolong Seiko to get a quotation.