You may be familiar with CNC machines and how many operations can be performed using them, and tapping is one of them. It is used to create internal threads inside the holes of parts, which is why it is widely used in the manufacturing industry. This article provides comprehensive information related to various aspects of tapping, its types, uses, and more.

What is Tapping in Machining?

The tapping process is one of the functions of CNC machine tools. Tapping is performed on a CNC machine tool to create internal threads within the holes of a part. These threads are necessary for a good fit between bolts and nuts, etc. Due to the automated nature of CNC machine tools, tapping can be done with great precision and efficiency.

What is the Purpose of a Tapping Machine?

The tapping machine is installed within the CNC machine tool. It is used to machine threads in pre-drilled holes of parts. Tapping machines are commonly used in the automotive industry as they can efficiently tap holes in automotive parts such as chassis housings, engine blocks, etc. Tapping is important because it needs to fully utilize the strength of connecting screws or bolts.

Best Aluminum CNC Tapping Machine Products

The main factors for the best aluminum processing are optimal spindle speed, torque, chip management, etc. For the best aluminum products, you should use the Brother Speedio series (R450X2, S700X2) because of its high-speed tapping and high precision. You can use the Makino F series because of its high-speed operation. There are many others, but these two are the best.

Advantages and Disadvantages of CNC Tapping

CNC tapping machines are automated and simple, so they are easy to use. As we discussed earlier, they are used to make internal threads. Now let’s find out the detailed advantages and disadvantages in this section.

Advantages

Cost-effectiveness

Since it is an automatic machine, only one skilled operator is needed to operate it. Once the feed rate is set, the automatic tapping machine runs on its own. Due to the less labor required, the cost is lower. That’s why it is a cost-effective technique for creating threads within components.

Productivity

After programming the feed rate on the machine, CNC tapping machines work automatically and at a fast speed. Their tapping speed is faster than that of manual machine tools. The fast tapping speed can improve productivity.

Consistent Quality

The possibility of errors during the working process is very low because it will work automatically until stopped by a third party. CNC tapping machines are used when strict hole diameter tolerances and high-quality threads are required.

Reduced Scrap and Rework

Due to the high efficiency of CNC tapping machines, they produce much less scrap compared to manual tapping machines. Their stable quality hardly results in any errors, so the rework rate is very low.

Repeatability

Once the thread design is programmed in CNC tapping, it can repeat the thread design on many components.

Safety

Automatic tapping machines are safer than manual ones because after programming, the machine does not require any workers, thereby reducing the risk of personal injury during the working process.

Disadvantages

Every machine has some disadvantages, and CNC tapping machines are no exception. Its main disadvantages are as follows:

- CNC tapping machines are very expensive, meaning a single machine requires a huge investment.

- To run this machine, complex programming is needed, which takes a lot of time.

- The machine cannot switch from one design to another in the workflow because the conversion takes a lot of time.

- Since the tap is always in contact with the workpiece, there is always a risk of tap breakage. The second reason is that the spindle speed is very important.

How Does the CNC Tapping Process Work?

The working principle of a CNC tapping machine is to pre-program the feed speed and design. The tapping tool moves at the feed speed to form threads on the surface. The tapping process starts with drilling, so a hole needs to be drilled to use the tapping process.

Step-by-Step Work

There are two main steps to start the work. The first step is to select the appropriate tap. These taps are formed using different tapping dies of the required size and shape. The tap drill is selected according to the thread design and size, screw size, material, and hole diameter.

Once the selected tap drill is installed on the machine, the operator should program the design and feed speed on the automatic tapping machine and ensure that the tapping tool is accurately set or suitable for the hole depth.

CNC Milling Tapping: A Versatile Solution for Milling and Tapping

Now, you know that tapping is a process of manufacturing internal threads in holes of parts such as nuts. Another process expressed in this title is the milling process. The milling process is used to manufacture parts with complex shapes by cutting off excess material. The name “CNC milling tapping” implies that we can perform both processes using this machine, which is why it is a versatile solution for milling and tapping.

What is Rigid Tapping? How Does It Work?

This is a tapping process that uses the synchronization of spindle speed and feed rate to match the pitch. It allows the production of consistent threads and control of blind holes.

Rigid tapping is a precision thread processing method used in CNC machining, where the machine keeps the spindle and tap perfectly synchronized. As the tap rotates, it moves down into the material at a controlled speed. Since the spindle and tap rotate together, there is no sliding or misalignment, resulting in clean and accurate threads.

This is different from “floating tapping”, where the tapping head has a certain flexibility to adjust for misalignment. In rigid tapping, the connection between the spindle and the tap is fixed, so the threads are more precise and consistent.

Rigid tapping is particularly suitable for mass production and applications requiring precise threads. If you plan to use rigid tapping in CNC machining, make sure your machine can handle it and that the tap you use is suitable for the material you are processing.

Types of Taps in CNC Tapping

There are many types of taps used in CNC tapping machines based on material, hole diameter, etc., but the most common ones are discussed here.

Spiral Point Taps

Such taps have straight flutes for distributing coolant during operation. When using these taps, chips are removed with the help of deep cuts at the cutting chamfer with the inclined angle at the front end of the tap. If the part contains a through hole, spiral point taps are used for tapping.

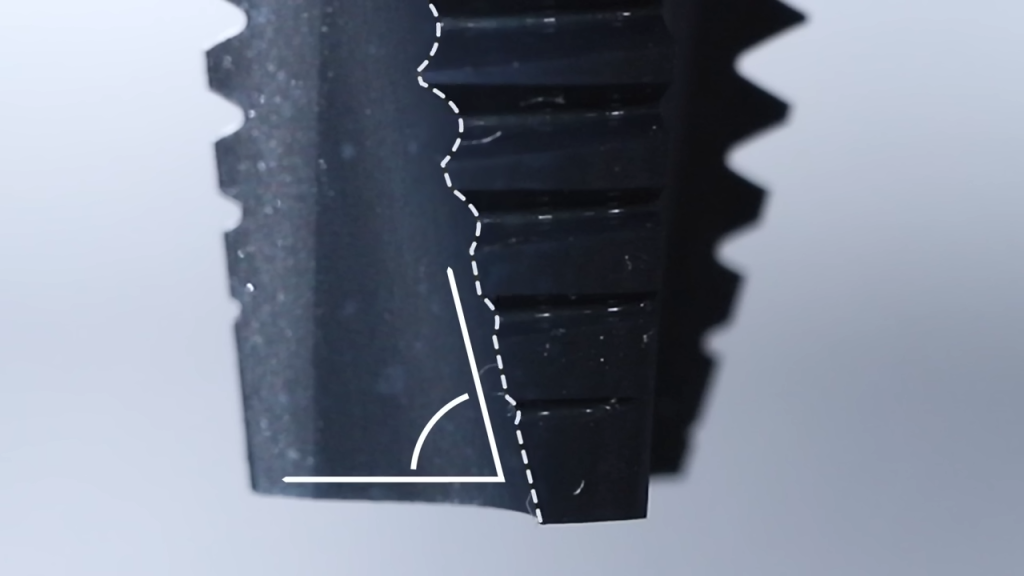

Spiral Flute Taps

In the following figure, we can see that the end of the spiral flute tap is flat. It removes material faster than any other tap because it has more cutting edges. To use these taps, there is a requirement for pre-tapping. These taps are used for blind holes and hard materials where chip accumulation is a problem.

Forming Taps or Roll Taps

As the name suggests, these taps roll the material instead of producing chips. They are non-fluted taps because there is no need to discharge chips from the surface.

CNC Tapping Tools and Accessories

CNC tapping tools include taps, tap holders, cooling taps, etc. Each tool has a different function. For example, cooling taps are used to provide channels for coolant to control heat during cutting tapping, and tap holders are used to fix taps, etc.

Accessories include tap speeders, depth stops, torque limiters, etc.

CNC Tapping Head

The tapping head controls the work of the tap. It is like the liver of a crane. When you press it down, the tap moves down and starts working, and when you pull it up, the tap returns to its original position, which means the work stops temporarily.

Selection and Setup of CNC Tapping Tools

The selection of taps depends on the workpiece material, hole diameter, screw size, and thread standard. The setup requires tap holders, feed rates, and coolant to control heat during cutting tapping.

Types of CNC Tapping Processes

There are several CNC tapping processes that can be used according to requirements. The most commonly used methods are introduced below.

Through Hole Tapping

This process is suitable for parts where the hole depth is equivalent to the thickness of the workpiece. This process usually uses spiral point taps and fluted taps. Since chips are discharged through the bottom of the hole, material removal is easy.

Blind Hole Tapping

The tapping process uses fluted taps. Because the depth of the hole does not penetrate the entire thickness of the workpiece, it is difficult to remove material due to the threads in the hole. These chips need to be manually removed from the hole.

Floating Tapping and Its Advantages

In the floating tapping process, as the name suggests, a floating bracket is used to fix the tap, allowing it to move slightly, or it can be said to float on the axis, to manage the misalignment between the workpiece and the machine spindle. Since there is no contact between the tap and the workpiece, the risk of tap breakage is lower.

Synchronous or Self-Reversing Tapping

This process is used to make threads at a faster speed, i.e., rapid production. Once the cycle is completed, the tap automatically returns to its original position, so we do not need to hold and control it in each cycle. This is a function to achieve rapid production.

Pecking

The tap continuously goes in and out in a circle until the thread is completed.

Forming Tapping

In this process, no chips are formed because the material is not removed but placed in a certain position within the hole. Forming taps are used in this process. This is a relatively clean process because there are no chips.

What is the CNC Tapping Formula?

There are two formulas used for tapping in CNC. One is for feed rate, and the other is for finding spindle speed.

Spindle Speed

S = (SFM × 3.82) / D

Here,

SFM is the cutting speed, and D is the tap diameter.

Feed Rate

F = RPM × TPI

RPM is the spindle speed, and TPI is the threads per inch. If the spindle moves at 1000 RPM to produce 20 TPI, the feed rate will be 50 IPM.

Cutting Speed

SFM = (S × D) / 3.82

Explanation of CNC Tapping G Codes

CNC (Computer Numerical Control) machines work through programming, i.e., G codes. G codes use their commands to control the functions of CNC machines. According to these codes, the tap can automatically reverse to its original position and rotate clockwise.

CNC Lathe Tapping Cycle Program

Common Applications of CNC Tapping

Since CNC tapping is an automated machine, it is very simple to operate. It can produce high-quality and precise threads in holes, which is why it is widely used in industries such as automotive (engine block cylinder heads, transmission housings, etc.), aerospace (landing gear, jet engine components, and avionics), electronics, and industrial equipment. Its applications show the importance of CNC tapping in the manufacturing field.

How to Improve the Performance of CNC Tapping

There are many aspects that can be optimized to improve CNC tapping performance. For example, the selection of taps is very important. The orientation and holding of the workpiece are important factors to consider during operation. Accurate feed rates and spindle speeds can improve performance. Sufficient lubrication is also important for performance.

Chinese CNC Tapping Service Provider: Debaolong Seiko

We provide you with the best CNC tapping services. To obtain precise sizes of internal threads such as screws, bolts, and nuts, please visit Debaolong Seiko. We will provide services at the best price within the delivery time.