American sportswear giant Nike has recently developed the world’s first 3D-printed autonomous sports bra entirely using the new FlyWeb material. This innovative product will make its debut in Paris on June 26, witnessing middle-distance runner Faith Kipyegon’s attempt to break the “four-minute mile” barrier. This marks Nike’s first application of additive manufacturing technology in functional apparel.

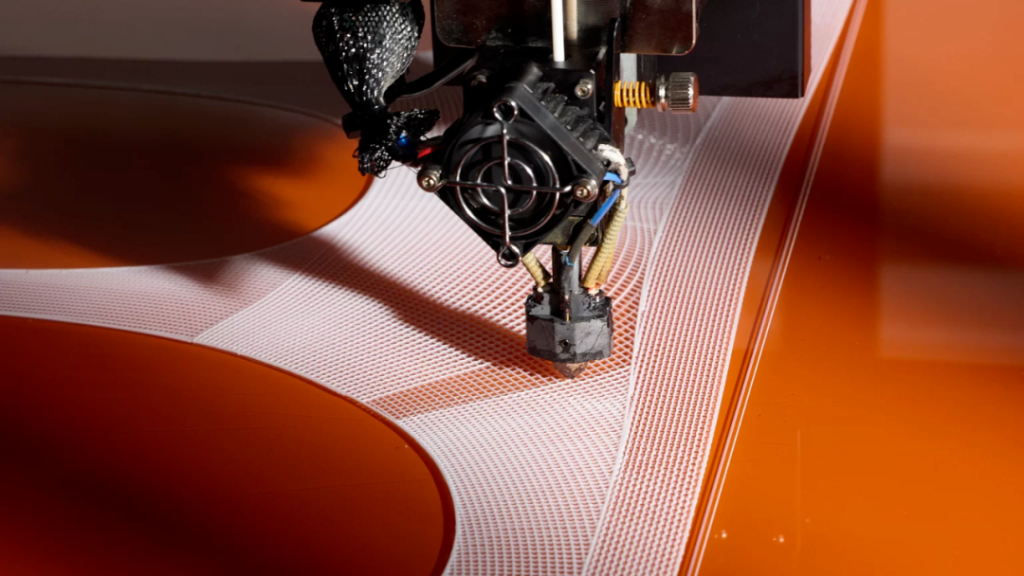

FlyWeb is made from thermoplastic polyurethane (TPU), a flexible polymer, and is produced via 3D printing rather than traditional knitting processes. The material is constructed by computer to form a seamless single-layer structure, allowing designers to control stretchability, breathability, and support by adjusting the density of different areas of the garment. Janet Nicol, Vice President of Innovation at Nike, stated: “We spent years reimagining—not just the material, but the entire design philosophy—to make FlyWeb combine softness, exceptional breathability, and aesthetic appeal.”

Close-up of the 3D printing process for Nike’s FlyWeb fabric

The research and development focused on sports bras, whose material structure has remained unchanged for decades. This printed design eliminates the multi-layer structure of traditional sports bras, enhancing air circulation and reducing moisture retention. Its support comes from structural design rather than compression, with higher-density printing used in areas requiring support. Nicol revealed that testers commonly feedback that “it feels like wearing nothing at all”: “The most common comment from testers is: it’s invisible yet provides amazing support.”

The accelerated development of FlyWeb coincided with Kipyegon’s “Breaking4” challenge plan. Nike’s design team quickly transformed the material from prototype to product for this event. Lisa Gibson, Senior Product Manager for Apparel Innovation, said: “Everyone contributed their wisdom, and we truly achieved collaborative teamwork. Miracles happen when the team unites with faith in Kipyegon and this moment.”

Single-layer design eliminates traditional seams and padding, achieving structural support and breathability through variable-density areas

FlyWeb can dynamically respond to the body without the need for seams, shoulder straps, or excess materials. Nicol noted that some testers felt air flowing across their chests while running for the first time: “Most women have never had this experience; we didn’t even expect to feel this while running.”

Although Nike has previously applied 3D printing to footwear products, FlyWeb signifies its official entry into the field of 3D-printed high-performance apparel. Industry observers believe this reflects the sportswear industry’s ongoing efforts to explore additive manufacturing for close-fitting applications. While no plans for other FlyWeb products have been announced, Nike stated that the project will continue to advance. Nicol emphasized: “This is not just a revolution in bras, but also opens a new era for future high-performance apparel design, making us rethink how athletes can enhance their sports experience through clothing.”

Middle-distance runner Faith Kipyegon training in the 3D-printed FlyWeb bra

Direct Applications of 3D Printing in Apparel and Textiles

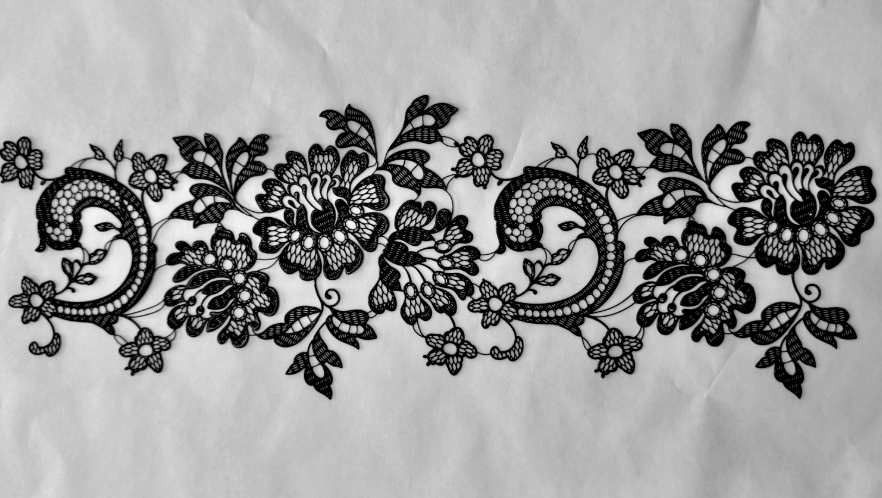

In recent years, with the development of direct-to-garment technology and on-demand customization, 3D printing has continued to expand the boundaries of fashion. In February this year, New York Embroidery Studio (NYES), which has participated in top events such as the MET Gala, introduced the Stratasys J850 TechStyle printer, enabling full-color 3D printing directly on fabrics. This technology can create precise three-dimensional decorations while reducing material waste. A year later, Stratasys launched Direct-to-Garment (D2G) technology supporting various fabrics such as denim and polyester. NYES stated that this technology is key to its sustainable production in high-end fashion and industrial applications.

Independent brands are also using 3D printing to break through traditional clothing manufacturing limitations. At the 2025 WINGS Independent Fashion Festival, Australian brand Amiss launched its first collection using Creality 3D tools: designers used the Otter Lite 3D scanner to capture natural textures, and the K2 Plus 3D printer to produce corsets, accessories, and structural garments on-site, shortening the prototype development cycle from weeks to within two hours, and 配合使用 Falcon2 Pro 60W laser cutter to produce custom fabrics. Co-founders Vanessa and Josh said this reduces costs, accelerates the development cycle, and enables fully autonomous production.

For more information, please contact us at Debaolong Seiko. You are also welcome to upload your designs to Debaolong Seiko for a quotation.