All manufacturing industries launch new products to stand out in competition with other sectors. The success of each product is crucial, relying on careful planning and execution across various stages from design and supply chain management to industrialization. In engineering, NPI (New Product Introduction) manages these activities as part of a core plan. This article provides insights to help industries efficiently transform ideas into products while minimizing risks.

What Is NPI (New Product Introduction) in Manufacturing?

NPI is a systematic approach in the manufacturing process that covers the entire journey from idea to final product. It is a key process for managing and optimizing the introduction of new products into production lines, ensuring product quality, cost-effectiveness, and efficiency.

NPI vs. Traditional Product Development

In manufacturing, NPI refers to the production and launch of new or improved products, emphasizing systematic, repeatable steps and supply chain management. Traditional product development covers the entire process from initial concept to commercialization, including design, verification, and industrialization.

Why Is New Product Introduction (NPI) Critical for Shortening Time-to-Market?

It is vital for accelerating time-to-market because it provides a systematic and structured process to move products from idea to market, reforming manufacturing, supply chains, and reducing bottlenecks.

Why Should NPI Be the First Step in Your Development?

In supply chains, NPI simplifies large-scale production processes, thereby shortening time-to-market, improving cost-effectiveness, and delivering higher-quality products.

NPI Manufacturing and CNC Machining

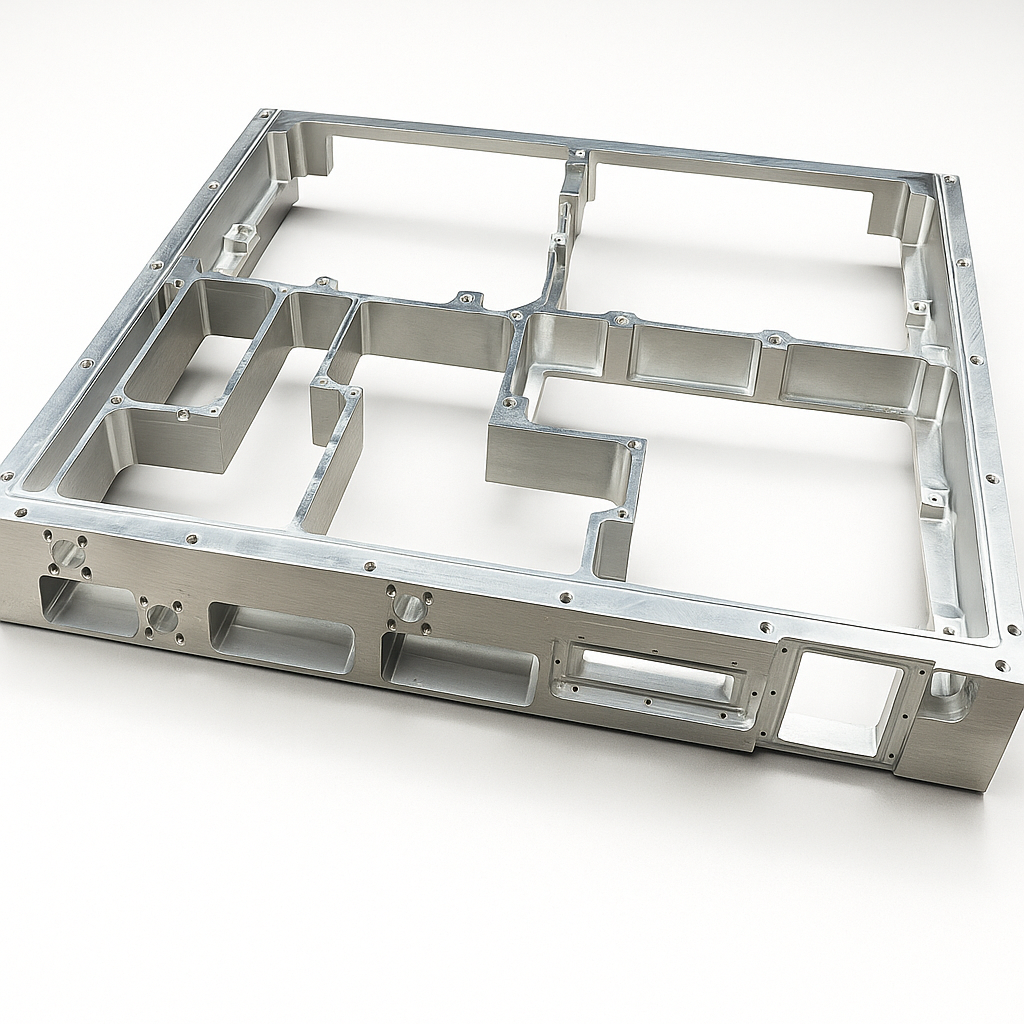

The combination of New Product Development (NPD) and CNC machining represents a structured approach to launching new products economically, especially when involving custom or complex designs (particularly in large batches).

6 Key Stages of a Robust NPI Process

A robust NPI process typically includes six key stages: definition, feasibility, design, CNC prototyping, verification, and product launch.

Stage 0 – Market and Concept Screening

It focuses on clearly presenting the product idea, features, and target market by understanding customer needs and identifying the product’s value proposition.

Stage 1 – Feasibility and Business Case

Assesses the feasibility of the product concept by evaluating technical feasibility, market demand, and financial impact in new product development.

Stage 2 – Detailed Design and DFM/DFA Review

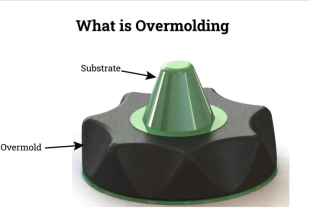

It concentrates on designing the product to clearly define the specifications and functional requirements of the prototype.

Stage 3 – Prototyping and EVT (Engineering Verification Test)

It focuses on creating prototypes that meet design specifications.

Stage 4 – DVT and PVT (Design/Production Validation)

This is a critical stage of product testing and verification to ensure the product meets quality standards and user expectations.

Stage 5 – Mass Production and Market Launch

It focuses on large-scale production to establish manufacturing processes, build supply chains, and prepare the product for launch in new product development.

What Are Verification Tests (EVT → DVT → PVT)?

Verification testing is a continuous process in product development to check product functionality and ensure it is manufacturable and suitable for mass production.

Engineering Verification Test (EVT)

This initial stage verifies the product design at the component level, conducting functional tests, performance evaluations, and ensuring each part meets specifications.

Design Verification Test (DVT)

It validates the mass production of the product and ensures all components integrate seamlessly by testing manufacturing tolerances and assembly processes.

Production Verification Test (PVT)

The final verification stage before mass production, where the product is tested in real-world environments.

What Are Cross-Functional Teams and Their Roles?

In NPI, cross-functional teams are groups of individuals with diverse functional backgrounds who collaborate to achieve common goals.

Product Management and Marketing

It ensures product development aligns with customer needs, business objectives, and market trends. The team works together to develop product features and functions based on customer requirements.

Engineering Design

The design team collaborates with engineers to use tools like CAD/CAM for Design for Manufacturability and Assembly (DFM/A) and analyze individual part tolerances accumulated in assembly, creating user-friendly products with high technical feasibility, reliability, and performance.

Manufacturing and Quality

The manufacturing team collaborates with engineers and quality control departments to verify product efficiency and cost-effectiveness while maintaining high quality. The quality control department identifies defects that cause products to fail to meet quality specifications.

Supply Chain and Procurement

Procurement involves activities such as identifying suppliers, negotiating contracts, and ensuring cost-effectiveness of material resources. The supply chain ensures materials are delivered on time and meet production schedules. Cross-functional operations can improve supplier relationships and shorten lead times.

How to Improve the NPI Process?

There are several ways to improve the NPI process, as described below:

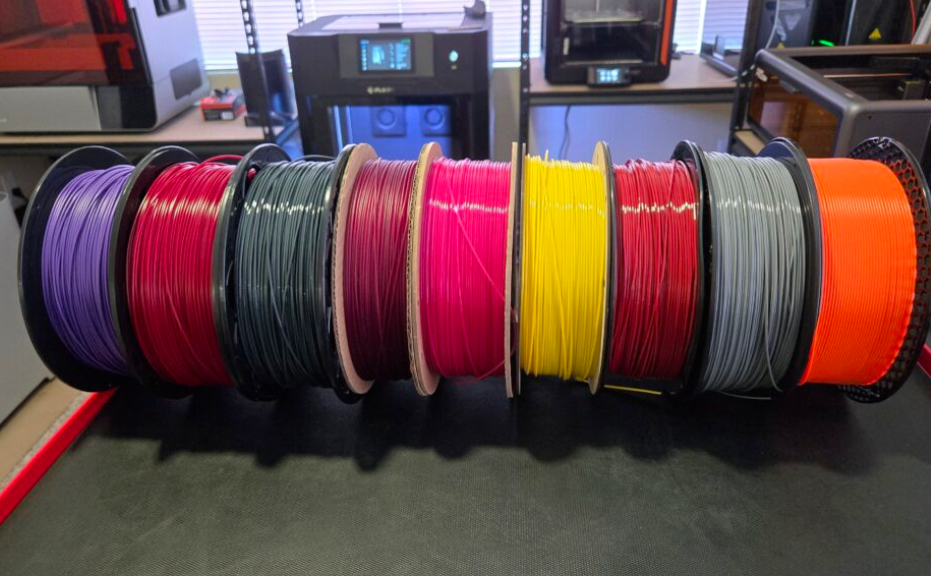

Build Rapid Prototypes First

It allows early testing and verification of design concepts and helps identify potential risks in the development stage.

Obtain Supplier Feedback Early

Collaboration with suppliers can provide valuable insights into manufacturing feasibility, material availability, and potential risks in the NPI process.

Track Progress Weekly

It establishes a regular rhythm of tracking progress through meetings or reports and identifies potential delays and bottlenecks.

Conduct Small-Scale Pilots Before Accelerating Production

It improves manufacturing processes before large-scale production, identifies potential risks on the assembly line, and verifies product quality at an early stage.

Rapid Prototyping and CNC in NPI

CNC machining enables quick and accurate design modifications, making it suitable for testing and verifying new designs in rapid CNC prototyping.

When to Use CNC Machining for Iteration

CNC machining allows rapid CNC prototyping, testing of new designs, and easy modifications and improvements for fast design iteration and testing.

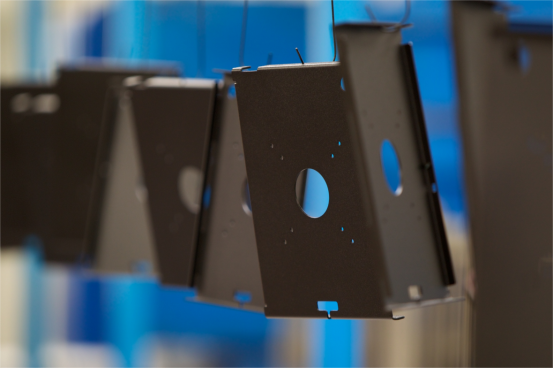

Bridge Tooling and Small-Batch Production Before Hard Tooling

In the design process, CNC is more economical than hard tooling, especially for bridge tooling and small-batch production. It shortens lead times and improves design stability without using expensive hard tooling.

Design Tips for Machining

To shorten CNC machining lead times and reduce costs, material selection is crucial, depending on machinability, cost, and performance. Designs with features including small details and sharp corners must be avoided, and realistic tolerances must be established.

NPI & NPD and Large-Batch CNC Machining

Large-batch CNC machining in NPI and NPD offers advantages such as efficiency, precision, and consistency, but it also has some disadvantages, as described below.

Advantages of Large-Batch CNC Machining

- It speeds up production and simplifies the mass production process in NPI and NPD.

- High accuracy and repeatability ensure product quality.

- CNC machines provide excellent consistency and uniformity in product quality.

- Reduces human error and minimizes heavy manual labor.

Disadvantages

- The initial cost of large-batch CNC machining for NPI and NPD is very high.

- Regular maintenance is required to achieve optimal performance.

- Complexity increases due to the need for professional knowledge and skills.

Conclusion

New Product Introduction (NPI) helps various industries minimize delays and quickly launch products to the market through careful planning and execution of product development and release. It ensures all stakeholders agree on the vision and scope, thereby minimizing rework and risks related to development and manufacturing. The combination of new product introduction and CNC machining allows precise control over the entire process from initial concept to final product.

For more information, please contact Debaolong Seiko. You are also welcome to upload your designs to Debaolong Seiko for a quotation.