When manufacturing plastic parts, choosing between CNC machining and 3D printing is often a difficult decision. This article will analyze the core differences between these two leading technologies. You will learn about their advantages, limitations, and optimal application scenarios—and when discussing mass production or cost-sensitive projects, you will also gain insights into alternative processes such as injection molding.

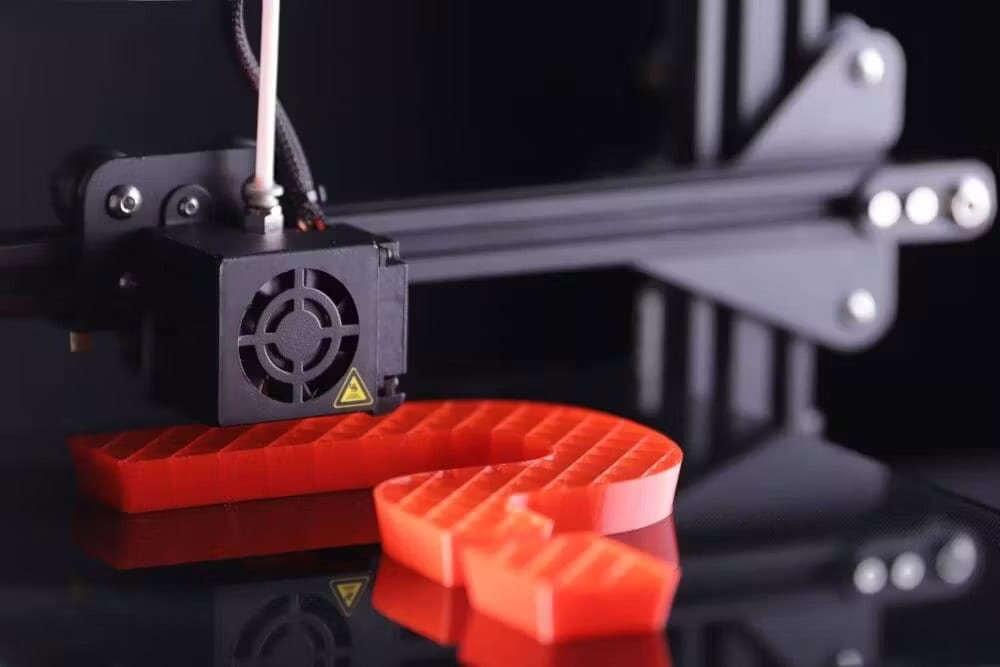

If you have ever struggled with choosing between CNC machining and 3D printing for a project, you are not alone in the industry. Although both are powerful solutions for manufacturing plastic parts, their applicable scenarios vary significantly based on needs. CNC machining is like a sculptor, carving out part shapes by precisely cutting materials; while 3D printing is like building a structure with bricks, constructing solid objects by layer-by-layer material deposition.

Subtractive Manufacturing vs. Additive Manufacturing

Each process has its unique advantages—CNC machining excels in high precision and material diversity, while 3D printing performs exceptionally well in complex geometries and rapid prototyping. Deciding which method to use requires considering multiple factors such as design complexity, material requirements, production speed, and budget.

Quick Reference Comparison Table

The following comparison table provides an intuitive comparison to help you evaluate the most suitable process for your needs, or determine whether a combination of both processes is required to achieve the best results.

| Factors | CNC Machining | 3D Printing |

|---|---|---|

| Design Complexity | • Suitable for parts with simple to medium complexity • Limited by machining constraints | • Skilled in handling complex geometric structures • Very suitable for internal features, lattice structures and undercut designs |

| Material Selection | • Wide range, including engineering plastics (such as PEEK, ABS) • Heat-resistant and reinforced options | • Limited but the optional range is constantly expanding • Includes choices of flexible materials and organic shapes |

| Mechanical Properties | • Sturdy and durable • Suitable for load-bearing and structural components | • Medium strength • Suitable for functional prototypes and lightweight parts |

| Dimensional Accuracy | • Suitable for strict tolerance requirements in aerospace and medical components (+0.025 – 0.125mm) | • Sufficient to meet applications with prototypes and small tolerance requirements (+0.3mm) |

| Large Part Size | • Maximum 2000×800×1000mm • Suitable for industrial casings and large-size prototypes | • Maximum 914×610×914mm (for example, FDM) • Suitable for small-size prototypes or components |

| Surface Treatment | • Smooth surface, no need for extensive post-processing (typical surface roughness after machining is 125Ra) | • Requires post-processing (such as sandblasting, painting) to obtain a smooth surface • The surface is usually rough and varies with the process (for example, FDM, SLA) |

| Lead Time | • Mass production, fast speed • Slow when applied to complex equipment | • Suitable for rapid prototyping of small batches and complex designs • Very suitable for rapid iteration and emergency replacement of parts |

| Prototype Manufacturing | • High cost for single or small-batch production • High precision for testing final designs | • Economical, efficient and fast • Suitable for design verification, trial assembly and assembly inspection |

| Cost | • High setup cost • Cost-effective for mass production | • Low setup cost • Economical for small-batch or customized single-piece production |

Checklist: Guide to Choosing Between Polymer CNC Machining and 3D Printing

Evaluate which manufacturing process best fits your project needs using this quick checklist. For each question, determine whether CNC machining, 3D printing, or a combination of both is the optimal solution.

- Do you need parts with uniform mechanical properties? If so, CNC machining is the best choice. Its isotropic components have consistent mechanical and thermal properties throughout the material, making them ideal for load-bearing applications or mechanical assemblies. 3D printed parts have anisotropic characteristics due to their layered structure.

- Is high tensile strength crucial for your parts? Then, choose CNC machining. When using the same material, CNC machined parts typically have 40-60% higher tensile strength than 3D printed parts, making them suitable for high-strength applications.

- Do you need to shorten the production cycle? Yes, choose 3D printing. Processes such as SLS usually take 3-5 working days, including setup, printing, and post-processing. In contrast, CNC machining has a longer lead time (usually more than 10 working days) due to the need for complex setup, programming, and tool preparation.

- Are you producing in small batches (1-10 pieces)? Then, 3D printing is your best choice. Due to extremely low setup requirements, the unit cost is lower for small-batch production.

- Are you producing in large batches (50 pieces or more)? Choose CNC machining. For mass production, it is more cost-effective because fixed costs can be spread over more parts.

- Do you need flexible materials, photosensitive polymers, or composite resins? Then 3D printing is suitable for you. It supports exclusive materials not available in CNC machining, such as TPU, TPE, special photosensitive resins, and composite resins.

- Is cost a major consideration?

- For small batches (1-10 pieces), 3D printing is more economical.

- For large batches (50 pieces or more), CNC machining is more cost-effective due to the amortization of fixed costs.

- For medium batches (10-50 pieces), MJF can be considered, as it can efficiently utilize the molding space and has reasonable costs.

- Do you need a manufacturing method that can be scaled to future production? Then, CNC machining is a better choice. It is suitable for medium to large batch production, and fixed costs can be spread through large batches. 3D printing excels in single-piece and small-batch production, and its cost advantage diminishes as the quantity increases.

Cost Drivers

了解 CNC 加工和 3D 打印的成本驱动因素可以帮助您优化设计并选择最具成本效益的工艺。从零件几何形状到所需的表面处理,某些特征会显著影响这两种工艺的生产成本。

| Description | CNC Machining (€) | 3D Printing (€) |

|---|---|---|

| Large, heavy geometries |  |  |

| Cored and lightweight features |  |  |

| Angled holes |  |  |

| Organic features |  |  |

| High-precision tolerance requirements |  |  |

| Excellent surface finish |  |  |

| Deep holes |  |  |

Considerations for Complex Geometric Features

Manufacturing feasibility is significantly affected by part geometry:

- Powder bed fusion processes (SLS, MJF) are suitable for producing complex free-form geometries with unsupported structures.

- FDM and SLA require sacrificial supports when the overhang angle >45°.

- CNC machining is limited by:

- Tool accessibility requirements

- Minimum inner circle radius limit based on tool diameter.

- Inability to manufacture closed internal features.

- Limited undercut capability

- If the part design includes complex internal structures, undercuts, or organic shapes that cannot be achieved by traditional subtractive manufacturing, additive manufacturing technology should be chosen.

Material Properties and Process Compatibility Matrix

When designing parts that combine CNC machining and 3D printing, selecting the appropriate polymer engineering materials is the first step. Ensure the compatibility of materials between the two processes to achieve performance and quality goals.

Some common materials, such as ABS, PA (nylon), and PC, are suitable for both CNC machining and 3D printing. 3D printing can also use special materials not applicable to CNC machining, such as flexible thermoplastics (TPU, TPE), photosensitive resins, composite materials, and CLIP resins (Carbon DLS).

When selecting the ideal material for your project, consider the following key factors:

- Mechanical requirements: Does it need to withstand high loads, impacts, or wear?

- Environmental exposure: Does it need to withstand extreme temperatures, chemicals, or ultraviolet rays?

- Process compatibility: Is the material suitable for the selected manufacturing method?

- Budget: Does the material cost meet the project goals?

The following table lists some common materials, their related properties, and the most suitable processes to help you make the right decision.

| Material | Properties | CNC Machining Applicability | 3D Printing Applicability | Compatibility/Multi-Process Part Application Scenarios |

|---|---|---|---|---|

| ABS (Acrylonitrile Butadiene Styrene) | Impact resistance, high toughness, medium strength; easy to process. | • Suitable for durable parts with complex shapes • Good dimensional stability | • Common material for FDM 3D printing • Medium detail and surface quality • Requires post-processing | Suitable for housings or parts that need to meet both machining precision and 3D printing complexity. |

| Nylon (Polyamide, PA) | High strength, wear resistance; self-lubricating. | • Suitable for gears, bushings, and structural parts • Easy to process | • Suitable for SLS, MJF, and FDM printing • Good elasticity and strength, easy to get damp | Suitable for gears, brackets, and structural parts, combining the advantages of both processes. |

| Polycarbonate (PC) | Impact resistance, high-temperature resistance, good transparency; easy to stress crack. | • Impact-resistant and high-temperature resistant • Need to be processed carefully | • 3D printing has high strength • FDM needs to be printed in a closed chamber to achieve thermal control | Suitable for protective covers, impact-resistant components, or combinations of machined and printed parts. |

| POM (Polyoxymethylene, Delrin) | High rigidity, low friction, excellent dimensional stability; wear resistance. | • Suitable for high-precision parts such as gears, cams, and bearings • Excellent surface finish | • Not commonly used in 3D printing, but can be achieved with special equipment (such as POM wire) | Most suitable for components that require high-precision machined parts and lightweight 3D printed parts. |

| PEEK (Polyether Ether Ketone) | Extremely high mechanical strength, chemical resistance, and high-temperature resistance. | • Preferred for aerospace, medical, and high-performance components • High cost but excellent precision | • Requires a dedicated 3D printer (FDM or SLS) • Extremely high strength but limited design flexibility | Suitable for components in harsh environments that require the combination of precision machining and complex 3D printing features. |

| PETG (Polyethylene Terephthalate Glycol) | Good chemical resistance, strength, and printability; more ductile than ABS. | • Suitable for transparent parts and scenarios requiring good mechanical properties | • Mostly used for FDM printing • Has strength, flexibility, and ease of use | Suitable for structural parts or housings that require the combination of machining precision and flexible printing. |

| Polypropylene (PP) | High fatigue resistance, chemical resistance, and flexibility; low density. | • Suitable for living hinges, chemical containers, and flexible parts • Difficult to machine | • Difficult to print, but can be achieved by optimizing hot bed adhesion technology • Flexible and durable | Suitable for chemical-resistant components or containers, which can combine printed features with machined components. |

Mechanical Property Comparison: CNC Machining vs. 3D Printing

Let’s compare the key differences in mechanical properties between materials such as ABS, PC, and PA12 when processed by CNC machining or 3D printing.

ABS (Acrylonitrile Butadiene Styrene)

| Property | CNC Machining | 3D Printing (FDM) |

|---|---|---|

| Tensile strength | 40-45 MPa | 30-35 MPa |

| Impact strength (Izod) | 200-220 J/m | 95-130 J/m |

| Elastic modulus | 2.3-2.4 GPa | 1.8-2.0 GPa |

| Compressive strength | 46-48 MPa | 35-40 MPa |

Key factors affecting 3D printing performance:

- FDM interlayer bonding strength.

- Printing direction (Z-axis direction performance is usually the weakest).

- Printing environment conditions.

- Internal filling rate (100% filling rate is used as a comparison).

PC (Polycarbonate)

| Property | CNC Machining | 3D Printing (FDM) |

|---|---|---|

| Tensile strength | 65-70 MPa | 55-60 MPa |

| Impact strength (Izod) | 600-850 J/m | 250-400 J/m |

| Elastic modulus | 2.3-2.4 GPa | 2.0-2.1 GPa |

| Compressive strength | 75-80 MPa | 60-65 MPa |

Key factors affecting 3D printing performance:

- Higher printing temperature requirements.

- Sensitivity to humidity during processing.

- Chamber temperature control.

- Cooling effect.

PA12 (Nylon 12)

| Property | CNC Machining | 3D Printing (SLS/MJF) |

|---|---|---|

| Tensile strength | 70-85 MPa | 48-55 MPa |

| Impact strength (Izod) | 150-180 J/m | 110-130 J/m |

| Elastic modulus | 1.7-1.8 GPa | 1.4-1.5 GPa |

| Compressive strength | 65-70 MPa | 50-55 MPa |

Key factors affecting 3D printing performance:

- Powder recovery effect.

- Sintering parameters.

- Part density.

- Post-processing method.

When to Choose Injection Molding Instead of CNC Machining or 3D Printing

Although CNC machining and 3D printing each have their advantages, in some cases, these two methods may not fully meet the requirements for cost-effectiveness, mass production, or high consistency. At this time, injection molding (IM) becomes a strong alternative. This process is especially suitable for large-scale production runs, complex designs, and applications with high requirements for precision and consistency.

The following are detailed explanations of when injection molding is more suitable:

- Focus on cost-effectiveness in large-scale production: Injection molding performs well in large-scale production because its upfront mold costs can be spread through the extremely low unit cost in mass production (such as the mass production of plastic containers). Although CNC machining and 3D printing can handle low to medium batch production, their costs become too high at this scale.

- Need consistent quality and flawless surface finish: If parts require strict dimensional tolerances or perfect surface finish, injection molding can achieve unparalleled uniformity in all products. This is particularly important in industries such as medical devices, electronics, and precision engineering, where high requirements for quality consistency are imposed.

- The design includes thin walls or complex features: CNC machining is difficult to handle thin-walled structures, while 3D printing can produce thin walls but may lack precision. Injection molding can easily reproduce complex features such as thin walls, living hinges, and undercuts, thanks to its high-precision molds (such as packaging parts with snap structures).

- Need multiple materials with specific properties: Injection molding supports a variety of materials, including advanced engineering plastics and custom formulations. This makes it very suitable for projects that require specific chemical, thermal, or mechanical properties, such as high UV resistance or chemical corrosion resistance.

Final Decision Guide for Polymer CNC Machining vs. 3D Printing

When to Choose CNC Machining

- When precision and durability are key: CNC machining excels in providing high dimensional accuracy and sturdy parts, suitable for fields that require long-term durability and precision, such as aerospace and medical components.

- When the expected production volume is large: For mass production, CNC machining becomes more economical over time because its initial costs are spread over more parts.

- When high-quality surface treatment is needed: CNC machining can obtain excellent surface finish with minimal post-processing, so it is suitable for components with high requirements for aesthetics or precise fitting.

When to Choose 3D Printing

- When rapid prototyping and design flexibility are needed: 3D printing is very suitable for rapid iteration of complex custom designs, because its technology can realize fine geometries and internal structures that are difficult or impossible to achieve by CNC machining.

- When focusing on environmental impact and material utilization: The additive manufacturing characteristic of 3D printing can minimize material waste, making it an excellent choice when sustainable development is a priority.

- When the production volume is low and the budget is limited: For small-batch production, 3D printing is usually more cost-effective because of its lower initial cost and faster production startup, suitable for prototypes or a small number of custom parts.

If both high precision and complex geometry are needed, a combination scheme that uses CNC machining for key tolerance areas and 3D printing for fine low-stress areas may have great potential. For more information, please contact Debaolong Seiko. You are also welcome to upload your design to Debaolong Seiko for a quotation.