What is Rapid Injection Molding (RIM)?

You have a complete design and some printed prototypes. You have engaged in traditional prototyping practices as much as possible. Now, you want to have a molded part for more accurate functional testing. Our standard lead time for molded parts is 15 days, and depending on the size and complexity of the part, the lead time can be as short as one day.

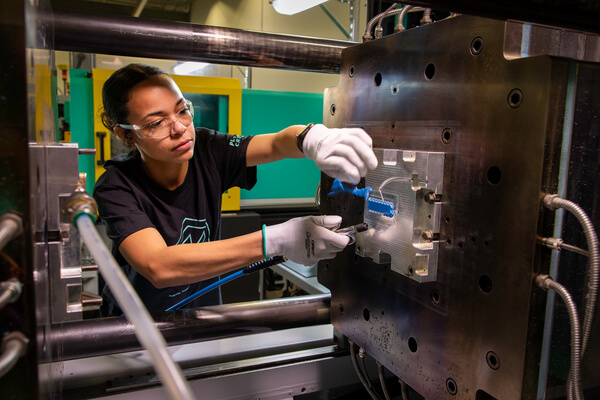

The rapid injection molding process starts like any molded part: you upload a CAD file to get a quote. Our Design for Manufacturability (DFM) analysis provides recommendations so that you can adjust the model early. Once the acceptable CAD file is ready, the tooling (mold) that will form the part can be created. This is done by machining aluminum blocks to form the cavity for manufacturing the part.

Traditional molds use steel as the base material. Although steel is tough and durable, this toughness means that the process of manufacturing the mold cavity is much longer. If you need parts quickly, that may not be suitable for you.

A quick note: If certain materials and high-temperature processes are used, RIM may require steel molds. Steel molds can better handle higher molding temperatures and are resistant to thermal expansion.

By replacing steel with aluminum, you get a material that is easier to mill, and this speed is crucial for getting parts faster. Although aluminum molds have a shorter service life than steel molds, you can easily get about 2,000 injections from each mold, which can get you through the early stages of the product or, if you need bridge production, which we will describe in more detail later.

Once the mold is made and the part is approved, our standard lead time for production parts is 10 days, and we can usually provide expedited delivery. This can make your lead time as short as one day, depending on the size and complexity of the part.

We offer secondary (post-molding) operations, including:

- Mold texturing and engraving

- Machining

- Pad printing

- UV printing

- Assembly

- Adding threaded inserts

- Laser engraving

- Part cleaning

- Packaging

Applications of Rapid Injection Molding

In four main scenarios, rapid injection molding can save you costs at critical moments.

- Rapid prototyping: Since aluminum molds can be cut in a shorter time, the molded parts will not slow down your product development process when they arrive.

- Small-batch production: When you need a small number of specific parts (fewer than 2,000), aluminum molds can produce the necessary parts without problems at low cost and with fast turnaround time. This scenario also applies to on-demand production, which often requires higher quantities, exceeding 2,000 parts.

- Line down: One of the more critical situations you may face that could affect the supply chain is a production shutdown or other problems faced by manufacturers. RIM can step in to keep the product on the market.

- Bridge production: Maybe you want to transition from prototyping to production but hope to do so at a more gradual pace. This is a typical example of when transition production can be used to navigate between various stages of the part life cycle.

- LSR injection molded parts being taken out of the machine

How Does Rapid Injection Molding Meet Industry-Specific Needs?

It’s not just about speed. With RIM, you can also reduce costs, simplify iterations, and quickly transition from prototyping to production-level manufacturing. Below, we highlight the advantages of rapid injection molding in four major industries, but we know that the points mentioned are equally applicable to all four industries.

Medical

Injection molding plays a crucial role in the medical industry as a reliable method for mass-producing complex, high-quality parts. A major advantage of injection-molded parts is the ability to quickly produce Liquid Silicone Rubber (LSR) parts, which is an important advantage in the FDA gating process. Using aluminum molds can speed up the process, allowing you to get approval faster and eventually achieve production.

Automotive

Injection molding is an integral part of the automotive industry, enabling manufacturers to mass-produce lightweight, durable, and high-precision components.

As the automotive industry continues to evolve, recently driven by electric and autonomous vehicles, suppliers are relying on rapid injection molding to prototype new designs and accelerate product development.

- High precision and consistency: Injection molding ensures tight tolerances, which is crucial for the precise fit of automotive components. Parts can be produced with consistent high precision, ensuring that each part fits perfectly into larger assemblies, which is essential for safety and performance.

- Efficient prototyping and design iteration: For new automotive designs, injection molding allows manufacturers to quickly prototype and test parts before investing in full production. This is particularly useful for innovative designs or custom parts, enabling efficient testing and modification.

Aerospace

The aerospace industry benefits from the ability of injection molding to quickly create prototypes for testing and validation. Engineers can quickly iterate on designs, optimizing the strength, weight, and aerodynamics of components before moving to full production.

Consumer Electronics

Electronic components, especially enclosures and internal fittings, require high precision to assemble correctly with sensitive internal hardware. The ability of injection molding to produce parts with tight tolerances ensures reliable fitting, helping to extend the service life of the equipment.

For more information, please contact us at Debaolong Seiko. You are also welcome to upload your designs to Debaolong Seiko for a quote.