Water jet cutting is a CNC cutting process that uses extremely high-pressure water jets to cut materials.

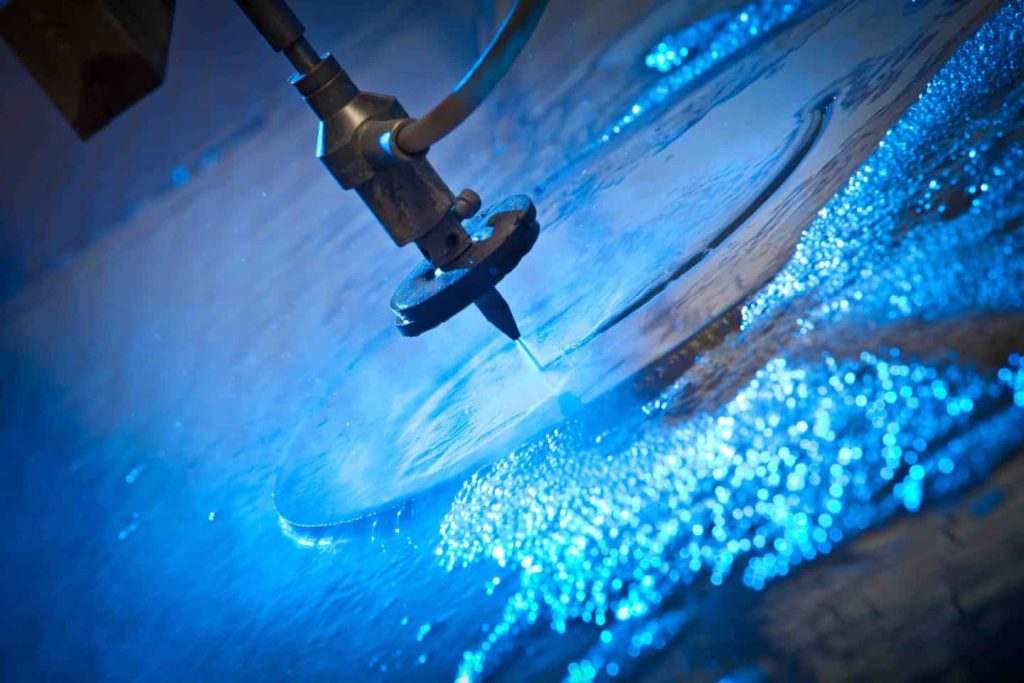

In this process, a high-pressure pump forces water through a dedicated pipeline and out through a nozzle at a very high speed (up to 900 meters per second). The nozzle focuses the water stream on the workpiece, which is controlled by CNC.

Types of Water Jets

There are two main types of water jets: pure water jets and abrasive water jets.

Abrasive water jets consist of a mixture of water and abrasive substances such as garnet and aluminum oxide.

On the other hand, pure water jets contain only pure water.

Materials

Water jet cutting can cut a variety of materials, including hard materials such as aluminum, steel, copper, other metals, and stone. It can also cut relatively soft materials such as wood, rubber, plastic, and paper. For cutting hard materials, abrasive water jets are used. Pure water is used for cutting soft materials. The maximum thickness that can be cut by this process depends on the material.

Advantages and Limitations

Compared with plasma cutting and laser cutting, water jet cutting has some advantages. Firstly, it is more precise among the three, with tolerances ranging from 0.05 to 0.1 mm. In addition, water jet cutting does not involve any heat, so there is no heat-affected zone in the workpiece. Because of this and the precision of water jet cutting, the parts produced by this process require little to no post-processing or finishing.

Other benefits of water jet cutting are its ability to cut complex and intricate shapes, minimal material waste, and the recyclability of the water used.

For more information, please contact us at Debaolong Seiko. You are also welcome to upload your designs to Debaolong Seiko for a quote.