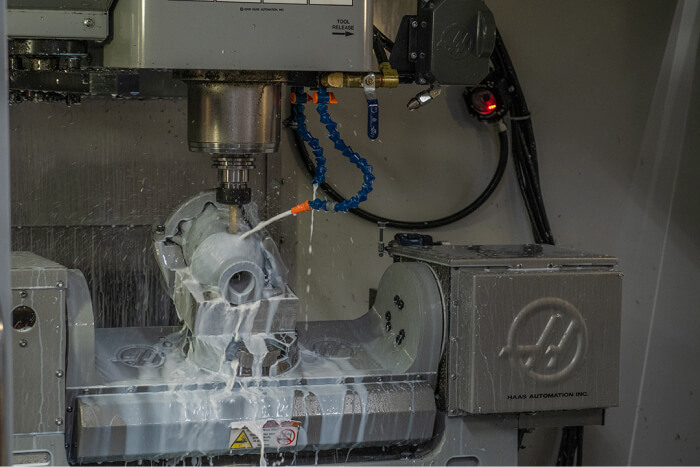

CNC machining offers numerous advantages. It is accurate, fast, and suitable for a variety of plastic and metal materials. Increasing the number of axes a milling machine operates on can significantly reduce the time required to manufacture parts. This is where 3+2 machining (also known as near-five-axis positioning) comes into play.

The ability to rotate parts mounted in fixtures improves the milling machine’s access to cutting surfaces. From a manufacturer’s perspective, 3+2 machining is much cheaper than full 5-axis machining, which means lower prices for your parts. There is also 2-axis machining, which can mill along the X and Y axes, allowing milling in two directions: left/right or up/down.

What is 3+2 Machining?

With the most basic milling machines, every time a new surface needs to be milled, the part must be removed and re-clamped to allow the tool to access the surface. This extra human intervention is, to say the least, very time-consuming. 3+2 machining adds rotational axes to the manufacturing process. These allow the fixed material to rotate on the A and C axes, so the mill can continue working on the X, Y, and Z axes as usual. The advantages are not to be underestimated:

Efficiency

- As mentioned earlier, 3+2 allows fewer setups, which means faster turnaround times.

- More precise cutting positions allow faster machining speeds with shorter, sturdier tools.

- Shorter tool paths provide enhanced access to more complex geometries.

Accuracy

It all comes down to setup. If you don’t have to re-clamp the part to reach a specific position, it’s possible to achieve tighter tolerances and higher precision. Human intervention in the milling process through setup always introduces the possibility of error.

Reduced Costs

It may not sound groundbreaking, but fewer setups also mean machining technicians don’t have to adjust the part’s position. Less machining time also means lower part costs.

More precise cutting also reduces material waste and the number of parts that need rework.

Higher Part Complexity

Whenever the accessibility of the end mill is improved, it can be pointed at the target more precisely. To this end, 3+2 milling improves the accuracy of complex parts, especially compared to 3-axis milling machines.

Applications of 3+2 Machining

This machining process is the first choice for complex housings and parts with angled features, etc. For example, injection molding utilizes the advantages of 3+2 to precisely machine the molds used to manufacture parts.

3+2 vs. 5-Axis CNC Machining

For most parts, 3+2 machining can get the job done without problems, but sometimes your parts have more complex geometries. That’s when 5-axis machining shines. Here’s a quick comparison of the two:

3+2 Axis

- More affordable.

- Easier to program.

- Works well when machining multiple faces but not all sides.

5-Axis

- Capable of machining very complex shapes, sometimes comparable to 3D printing for extreme geometries.

- Can reduce machining time due to continuous tool path control.

- Usually does not require multiple setups.

Design Considerations for 3+2 Machining

For most parts, 3+2 machining can get the job done for you quickly and accurately. For more information, please contact us at Debaolong Seiko. You are also welcome to upload your designs to Debaolong Seiko for a quote.