Humanoid robots are becoming increasingly prevalent as key hardware and software breakthroughs overcome long-standing barriers to creating viable and high-performance systems. These robots are being adopted more and more in manufacturing and related sectors to perform tasks traditionally handled by humans.

These humanoid robots are designed to replicate, replace, and enhance human capabilities. They bring operational flexibility, durability, cost-effectiveness, and enhanced safety to manufacturing, healthcare, warehousing, and other operations.

This article will discuss what humanoid robots are, their roles, key applications, the technologies enabling them, and opportunities for robot component manufacturers.

What Are Humanoid Robots?

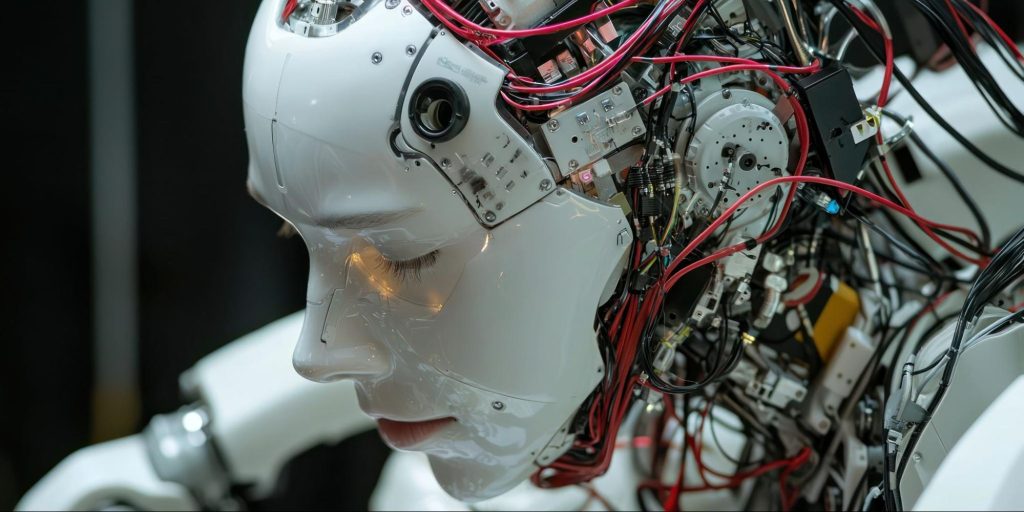

Humanoid robots typically feature bipedal legs, multi-jointed arms, adaptive hand-like end-effectors, and composite sensory inputs, designed to operate in human environments. In contrast, traditional automation relies mainly on specialized, single-purpose machines with limited adaptability.

Humanoid, self-propelled, and highly adaptive platforms offer new versatility. The robotics industry is keen to emphasize that these robots are not positioned as replacements but as key supplements in areas with high employee turnover, labor shortages, and higher risks to humans.

Core Technologies and Capabilities of Humanoid Robots in Manufacturing

Current examples of humanoid robots approaching commercialization in manufacturing integrate advanced mechatronics and real-time layered sensor fusion. These systems are guided by AI-supervised micro and macro motion planning with continuous correction capabilities. Key features include:

- Dexterous manipulation: Multi-articulated arms and end-effectors enable fine motor control to perform detailed tasks such as high-precision picking, orienting, placing, connecting, and wiring.

- Mobility and balance: Balanced and agile bipedal movement allows navigation in human-optimized workspaces, including those with stairs, ladders, and uneven floors.

- Machine vision and multi-sensory situational awareness: Integrated cameras, LiDAR, and tactile sensors provide data for object recognition, collision avoidance, and effective interaction in complex and often unpredictable environments.

- Artificial intelligence and machine learning: Reinforcement learning (informed by balance sensors, visual models, and error correction/recognition) enables adaptive behavior, mastery planning, and navigation in dynamic environments.

These capabilities allow the latest generation of humanoid robots in manufacturing to switch between tasks and adapt to unstructured human environments, new tools, or fixtures. They can now work safely alongside humans with minimal changes to the workspace and no risk to personnel.

Why Are Manufacturers Exploring Humanoid Robots Now?

Humanoid robots offer functional and commercial advantages that address several long-term challenges faced by manufacturers, including:

Labor Shortages

Labor shortages continue to impact industries such as logistics, product assembly, and warehousing. These roles are often repetitive, physically demanding, and unattractive to human workers, especially in high-value economies or aging populations. By integrating humanoid robots, companies can fill labor gaps and maintain production continuity, addressing a range of personnel challenges.

Human Safety Risks

Various tasks and operating environments in manufacturing are inherently hazardous to humans. Repetitive strain injuries, awkward body mechanics, heavy lifting, high temperatures, and chemical or radiation exposure can cause long-term health issues. Humanoid robots are better suited for these roles, reducing injury rates and improving workplace ergonomics. Their ability to consistently perform precise, repetitive movements without fatigue or distraction also enhances product quality.

Operational Flexibility

Humanoid robots align with existing factory infrastructure. Manufacturing environments are typically human-adapted. Tools, controls, transport paths, and safety systems are all designed for the human body.

Unlike traditional industrial robots that require dedicated and isolated operating environments, humanoid robots can operate (and collaborate) using the same tools and in the same spaces as humans. This compatibility minimizes integration burdens and allows for gradual task handover as circumstances evolve.

Easy Reconfiguration

Traditional automation is fixed-purpose and costly to reassign (often impossible). Thanks to recent advances in AI, including large language models (LLMs) like ChatGPT, it will be possible to assign a variety of tasks to a single humanoid robot throughout a shift. This enables manufacturers to dynamically reallocate robotic labor as production needs evolve.

Market leaders such as Tesla, Agility Robotics, Apptronik, Hyundai, Persona AI, and Figure AI are actively deploying or trialing humanoid robots in logistics, assembly, and warehousing tasks. These early deployments mark a shift from proof-of-concept demonstrations to partial operational integration in fast-paced, high-value environments. The range of activities being trialed, from material movement to light assembly, indicates confidence in the functional capabilities and economic viability of humanoid robots.

Trial reports cite the flexibility of robotic workforce deployment and reduced downtime in situations where human labor is difficult to source or retain, or simply not economical. As performance data accumulates and positive return-on-investment cases become known and quantified, pilot projects will expand to full-scale deployments across different industries and operation types. However, this is a rapidly changing industry with highly unpredictable timelines. For example, in 2024, Goldman Sachs raised its forecast for the humanoid robot market in 2035 (from just one year earlier) sixfold, to $38 billion.

Opportunities for Robotics Companies and Component Manufacturers

The emergence of humanoid robots both relies on and drives the development of new products, creating opportunities for humanoid robotics companies and custom parts manufacturers. Key areas of opportunity include:

- Drive systems: Humanoid robots require compact, high-torque actuators with lightweight housings and complex mounting geometries. Precision-machined housings, custom brackets, and linkages are often needed to meet space constraints and motion requirements.

- Thermally integrated battery enclosures: Modular lithium-ion battery packs require custom enclosures with integrated thermal management features (such as cooling channels or heat-dissipating structures), often customized to fit irregular form factors.

- Sensor mounting and enclosure solutions: Multi-modal sensor arrays (visual, LiDAR, tactile, inertial) must be integrated into dense, confined spaces. This requires custom mechanical mounts, protective enclosures, and alignment fixtures—all designed to maintain calibration while withstanding vibration and operation.

- External structures and skins: Protective enclosures, panels, and articulated covers must balance durability, aesthetics, and tactile functionality. These are often complex organic geometries requiring custom manufacturing methods and iterative prototyping.

Manufacturers with capabilities in custom mechanical design, rapid prototyping, low-volume production, and tight-tolerance machining are in high demand. The ability to iterate quickly and offer a wide range of materials from lightweight alloys to elastomers will be crucial.

As humanoid systems move from research laboratories to real-world deployments, companies able to provide highly customized, production-ready components will become vital partners in scaling next-generation robotics technology.

Current Challenges and Limitations in Humanoid Robot Manufacturing

Despite the promising prospects, integrating humanoid robots into manufacturing faces significant challenges:

- Cost: Current humanoid robot equipment ranges in price from $80,000 to over $300,000 per unit, excluding integration costs.

- Speed and strength limitations: Most humanoid robots move more slowly and can lift less than dedicated and fixed industrial automation.

- Safety: Despite design intentions, ensuring safe interaction with human workers in fast-paced environments requires extensive testing before it can be implicitly assumed.

- Battery life and thermal management: Powering multiple actuators and sensor/control systems is energy-intensive. Run times per charge are typically less than 8 hours and can be significantly shorter in high-demand operations.

Preparing for the Future of Human-Robot Collaboration in Manufacturing

The path to optimizing automation integration begins with a systematic assessment of the current state of operations. Manufacturers should first conduct a thorough audit of their existing infrastructure, examining production lines, micro and macro logistics routes, and service processes. The aim is to identify repetitive, physically demanding, or ergonomically hazardous jobs that are not only difficult to staff but also pose long-term health risks to human workers. These are ideal tasks for adaptive humanoid automation in manufacturing.

Ideally, the audit will seek out operations already built around human-scale and capabilities. Workstations that use multiple hand tools in different directions, operate in tight storage environments with narrow aisles and cluttered contents in small item bins, or are designed around standard human reach layouts can often be made more compatible with robots without extensive redesign. Hybrid workflows, where robots (cobots) assist rather than replace humans, should also be considered in mapping. These insights will feed into a phased deployment roadmap, allowing companies to introduce such automation strategically and incrementally.

It is also important to engage in exploratory discussions with robot OEMs (original equipment manufacturers) and integrators. Collaborating at the concept stage enables (knowledgeable) supply chains to help define fixture development that leverages a broader range of practical use cases. Sharing process data, developing deployment plans, and modifying system functions and software capabilities will shorten the time to commercial operation for robots. Close collaboration with the supply chain will ease initial frictions in placing robots in the work environment. The same collaboration will also make downstream revisions and re-implementations faster and smoother, maintaining dynamic workflows for system operation and maintenance.

To improve workplace automation readiness, organizations should proactively apply adaptable and robot-friendly design principles, adopt modular tools and standardized fixtures, and design accessible environments. Using digital twins and simulations can virtually test robotic workflows during the specification phase and in later revisions and reapplications. Adopting a “design for robotic manufacturing” approach to new products and services and their operational and manufacturing environments will ensure that flexible automation implementations are resilient, scalable, and future-proof.

Crucially, the human workforce must be able to adapt to this new paradigm and drive adjustments in tool usage patterns as applications evolve and adapt. Employees at all levels (and the AI interacting with them) must be capable of safe, productive interaction and assist each other in optimization. Investing in human capital ensures smoother adoption and long-term operational resilience.

Leveraging Digital Platforms for Next-Generation Manufacturing

Humanoid robots represent the inevitable next step in industrial automation and Industry 4.0. By combining near-human flexibility with machine precision and endurance, they are deliberately designed to operate in environments built for humans. Their initial integration into manufacturing and related environments has already accelerated innovation, reduced downtime, and unlocked new levels of productivity.

To support the next wave of automation, manufacturers need agile, responsive partners. Debaolong Seiko offers end-to-end custom manufacturing services, including CNC machining, 3D printing, injection molding, and sheet metal fabrication. Our rapid prototyping and production capabilities enable robotics innovators to move from concept to deployment faster than ever before.