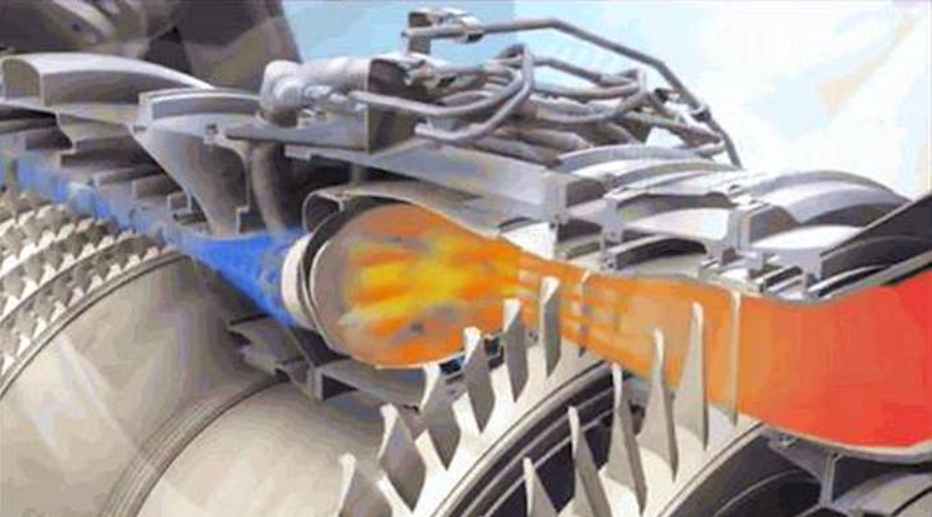

Fuel injectors are among the most critical components in combustion chambers. Their function is to atomize liquid fuel into a fine particle cloud, enabling effective mixing of liquid/gaseous fuel with air and generating a stable flame at the head of the combustion chamber.

Challenges Faced by Traditional Technologies

Due to the presence of holes, fuel pipes, swirl vanes, and complex internal channels, injectors need to be processed in multiple parts. During machining and assembly, multiple processes must be designed to ensure requirements for dimensions, precision, roughness, and sealing are met. Additionally, the emergence of multi-stage injectors has further increased the number of fuel/gas channels: fuel channels have increased from 1-2 stages to 2-4 stages, and air flow channels from 2-3 stages to 3-6 stages. Meanwhile, the number of injector components has risen from 5-10 to over 20. The increased structural complexity has led to significant difficulties in component assembly and welding, necessitating structural design optimization to avoid assembly issues and leaks.

Advantages of 3D Printing Technology

The application of additive manufacturing technology in fuel injectors will greatly advance injector research. Its advantages in injector development are reflected in the following aspects:

- Reducing machining and assembly processes: As additive manufacturing is a one-time processing technology, only a 3D model of the injector that meets design requirements needs to be provided.

- Enabling complex structural designs: Multi-stage swirl structures that are difficult to achieve with traditional machining methods can be realized through additive manufacturing using 3D models.

- Ensuring sealing requirements: Without welding processes, the sealing of fuel and air flow channels can be better guaranteed.

- High dimensional precision: The maximum precision of additive manufacturing technology is at the micrometer level, which fully meets the millimetre-level processing limit requirements of injectors.

- Short production cycle: Due to the reduced number of processes in additive manufacturing, the “additive” rather than “subtractive” approach is bound to shorten the processing time compared to traditional methods.

For more information, please contact Debaolong Seiko. You are also welcome to upload your design to Debaolong Seiko for a quotation.