Due to the COVID-19 pandemic, the demand for infrared forehead thermometers has surged. This device plays a crucial role in screening suspected patients in public places and is an important tool in the fight against the epidemic.

Despite active production mobilization, supplies remain insufficient due to the resumption of large-scale work and the ongoing spread of the epidemic worldwide.

Currently, the industrial production chain of infrared forehead thermometers is hindered by component shortages, resulting in relatively low production capacity.

To manufacture an infrared forehead thermometer, components such as an ABS plastic shell, PCB board, IC, resistor, capacitor, infrared sensor, LCD display, BLUs, battery cable clips, and many others are required. Producing a plastic shell using molds takes a certain amount of time.

3D Printed Thermometers

How to accelerate product development and save costs through 3D digital solutions?

3D scanning + 3D printing: suitable for small batches with high production efficiency.

1.Acquiring precise 3D data

Equipped with the industrial-grade Shining 3D OptimScan 5M 3D scanner, precise 3D data of the infrared forehead thermometer shell can be obtained within 15 minutes.

2.Data processing

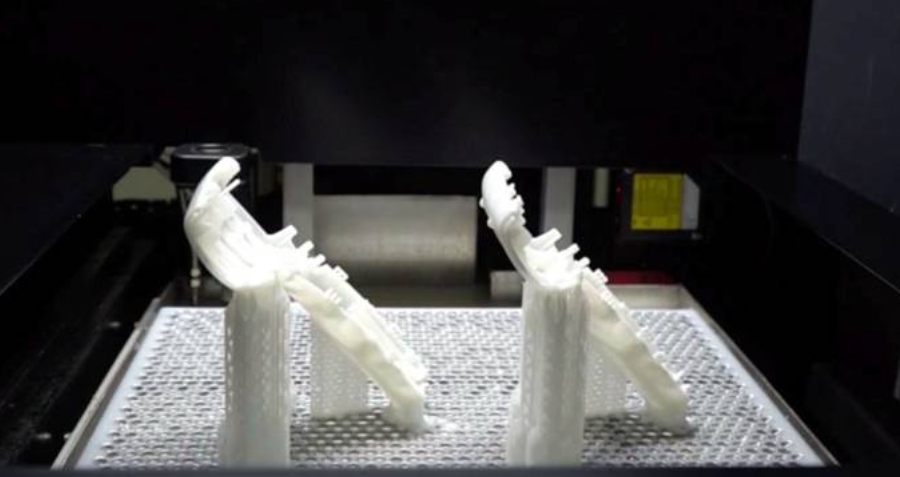

3.3D printing technology

Printing the thermometer shell on the EP-A350 resin 3D printer takes 4 hours, with a construction accuracy of ±0.08 mm and a scanning speed of 6-10 m/s.

Completing the production of infrared forehead thermometers

High-precision 3D scanning and 3D printing effectively reduce valuable production time and costs.

With 3D scanning and 3D printing technologies, we can combat time more effectively and win the battle against the epidemic.

For more information, please contact Debaolong Seiko. You are also welcome to upload your design to Debaolong Seiko for a quotation.