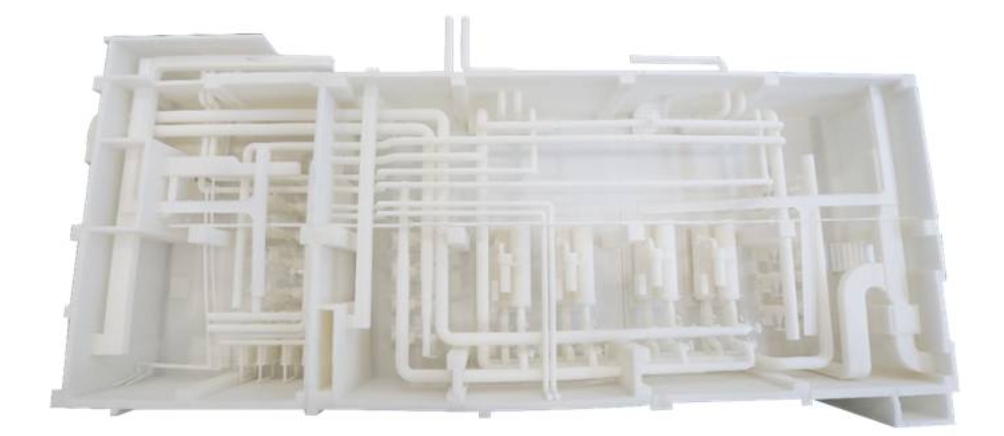

Polymers are the most commonly used 3D printing materials due to their lower prototyping and production costs compared to other 3D printing materials.

– PA12 Powder

PA12 is made from fine polyamide powder. Compared with traditional 3D printing plastic materials, PA12 has good water resistance and excellent resistance to chemicals such as alcohol, fuel, detergents, and oils. Most importantly, it is very suitable for high-temperature applications. The melting point of PA12 is approximately 180°C, and it can be safely used at temperatures below 95°C.

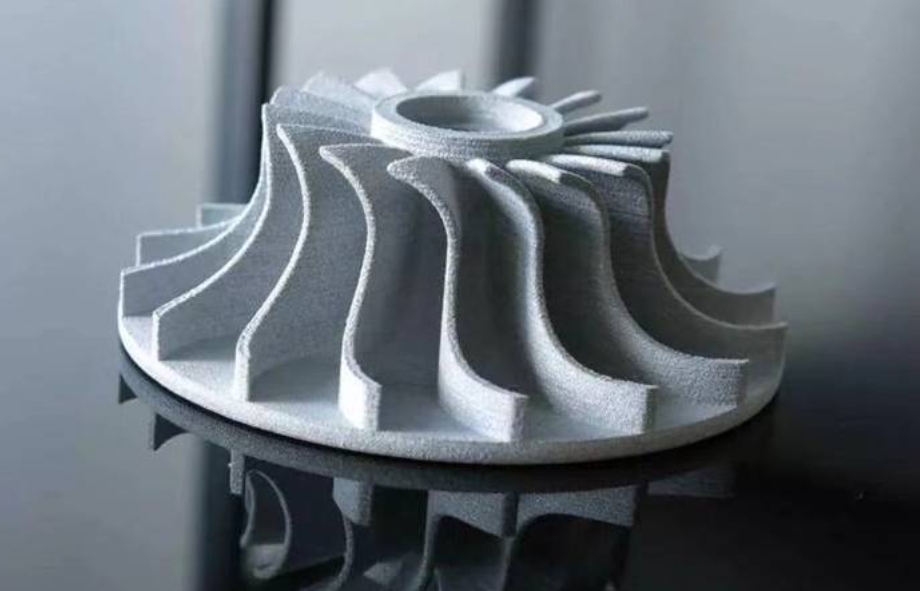

– Aluminum-Filled Nylon Powder

Aluminum-filled nylon powder is a mixture of nylon powder and aluminum particles. As a reinforced nylon, it has excellent durability and physical properties. The melting point of aluminum-filled nylon ranges from 172-180°C, and its softening temperature is 169°C, making it an optimal choice for parts requiring good mechanical properties and high-temperature resistance.

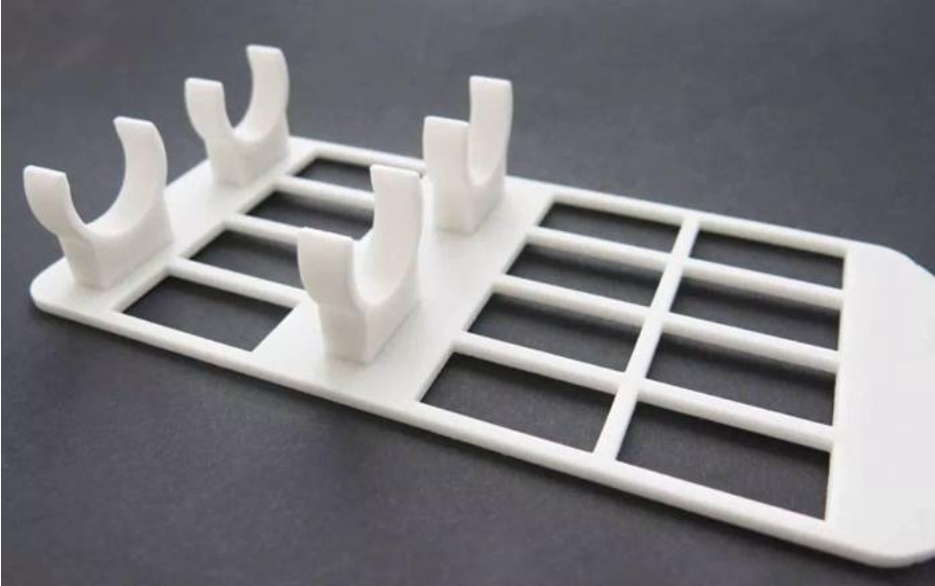

– Glass-Filled Nylon Powder

Glass-filled nylon powder is a mixture of nylon powder and glass beads, which is more durable than standard nylon powder. This material has good wear resistance, high strength, and easy meltability, with a melting point of 176°C. It can be used in high-temperature conditions or scenarios requiring a high heat distortion temperature.

Nylon glass-filled parts feature good heat resistance, excellent dimensional stability, and strong thermal aging stability, and can be directly used in the automotive industry, power tools, and prototype manufacturing.

For more information, please contact Debaolong Seiko. You are also welcome to upload your design to Debaolong Seiko for a quotation.