Today, the promise of industrial-grade 3D printing (additive manufacturing) as an end-use production method has been largely realized through a range of additive processes that deliver functional products across industries.

Examples abound: automotive motor brackets, jet engine fuel nozzles, aircraft cabin supports, custom hearing aids, surgical tools, and more.

But make no mistake—3D printing began as a powerful prototyping tool, and it remains one. That is its legacy. Early 3D printing technologies, developed in the 1980s and partly pioneered by the invention of stereolithography (SLA), enabled product designers to create 3D models and physical objects or prototypes.

I see this every day at Debaolong Seiko, where product developers choose from our six industrial-grade 3D printing processes to build, test, and iterate on innovative custom parts and products.

With this prototyping legacy in mind, here are five ways 3D printing enriches product design.

Enabling Early-Stage Product Development

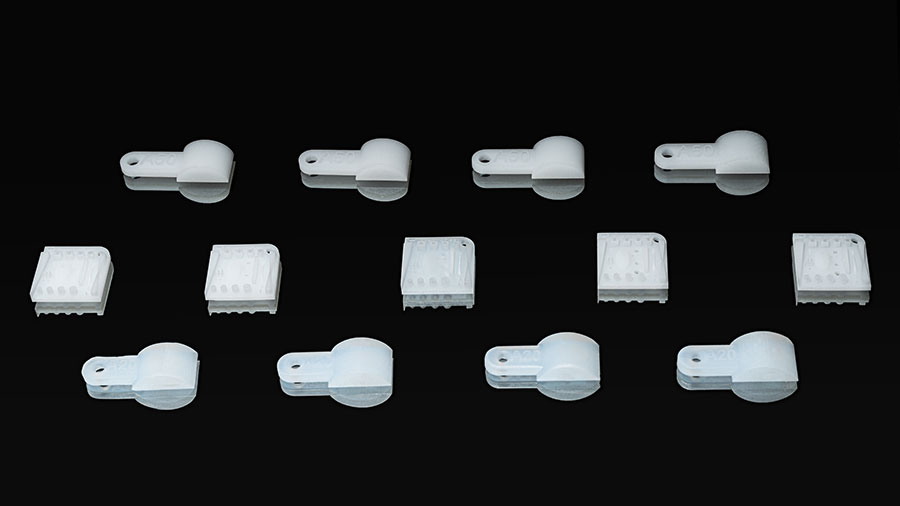

As a product developer, you may have an overarching idea for a part or entire product, and you know you can alter and refine the design in SolidWorks or other software. But at some point, you need to see a physical prototype. 3D printing allows you to create multiple iterations of the product’s design, shape, and dimensions—quickly. In other words, rapid prototyping.

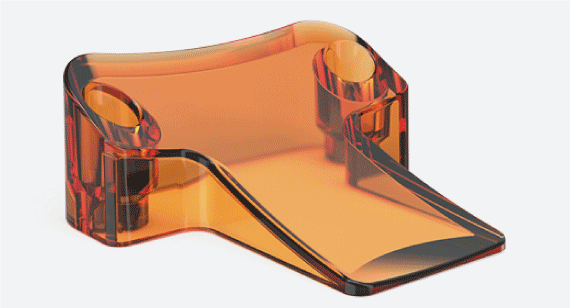

And, depending on the methods and materials used in prototyping, your possibilities are endless. An example? Lately, I’ve seen more designers using 3D-printed transparent prototypes, so that as they iterate on various designs, the clear models let them see what’s happening inside the part. Consider a power drill: there’s a lot going on inside it. With a clear prototype version of a new drill model, designers can visualize the internal mechanisms. But again, this is just one of hundreds of examples.

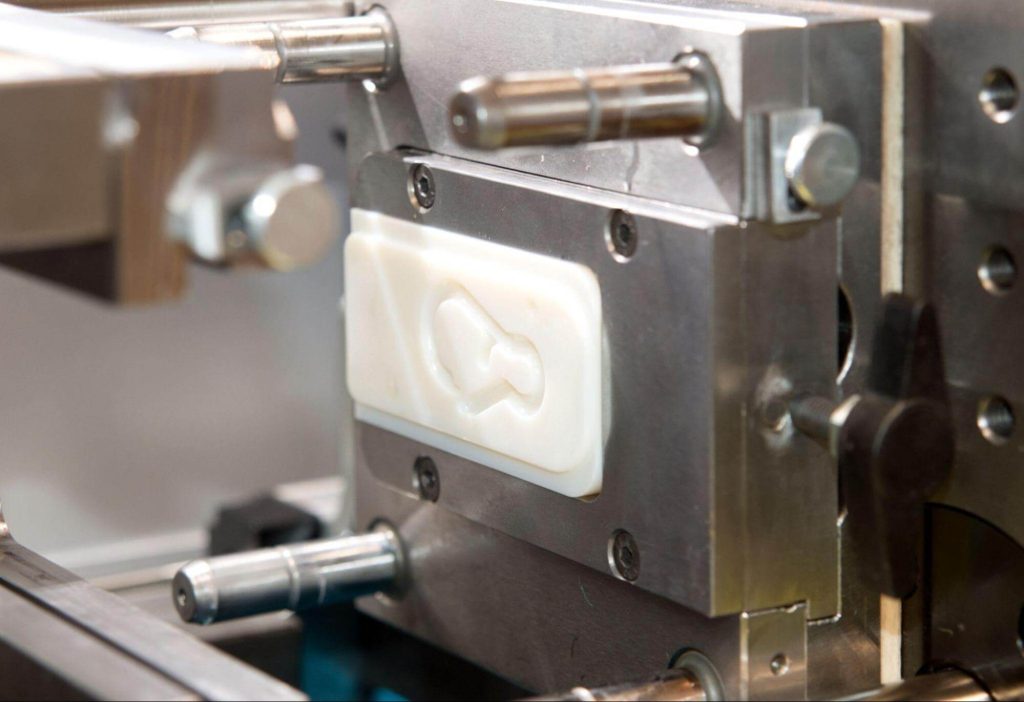

Of course, most of these parts will eventually be manufactured using injection molding or other traditional methods, but 3D-printed prototypes aid in overall design development.

Supporting Product Design Validation

I’m referring here to the early design and ideation phase, where product designers use 3D printing to develop “looks-like” prototypes—focused on the overall appearance of a part or product and its commercial appeal. This stage is where developers gather early customer feedback: Does it look right? Does it feel right? Does the product meet market needs? Again, 3D printing allows developers to create multiple design iterations. Take smartphone designers we’ve worked with, for instance: they iterate on tall, wide, thick, thin, small, large devices, and more. The key point is that the physical prototypes handed to customers for review are often 3D-printed.

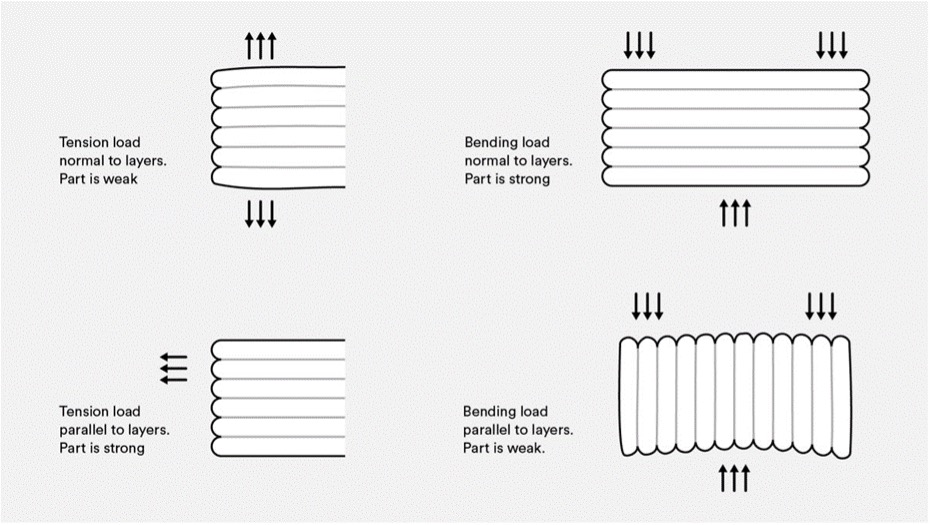

Facilitating Functional Validation

Here, I mean engineering validation—testing a part’s functionality. These are “works-like” prototypes, focused on the overall function of a part or product and how it actually performs. With 3D printing, you may not always be able to print using traditionally manufactured materials; however, because Debaolong Seiko offers so many 3DP processes, you can test most of the functions you might intend for your part design, whether through impact testing, airflow testing, temperature testing, or more. Again, the beauty of 3D printing? You can quickly experiment with multiple designs and prototypes.

Reducing Multi-Part Assemblies

This comes into play on the production side of additive manufacturing, when end-use parts will be 3D-printed. It’s one of the most often-cited benefits of additive: the ability to consolidate existing part assemblies made of many components into a single part. As we’ve previously covered in our part consolidation guide, if you’ve flown on a newer airplane, you’ve likely experienced this without realizing it. The aerospace industry’s most famous example is GE’s additively manufactured fuel nozzle for CFM International’s LEAP aircraft engine. The nozzle—a 20-part engine component—was redesigned as a single part, reducing weight by 25%.

Providing Design and Development Exit Ramps

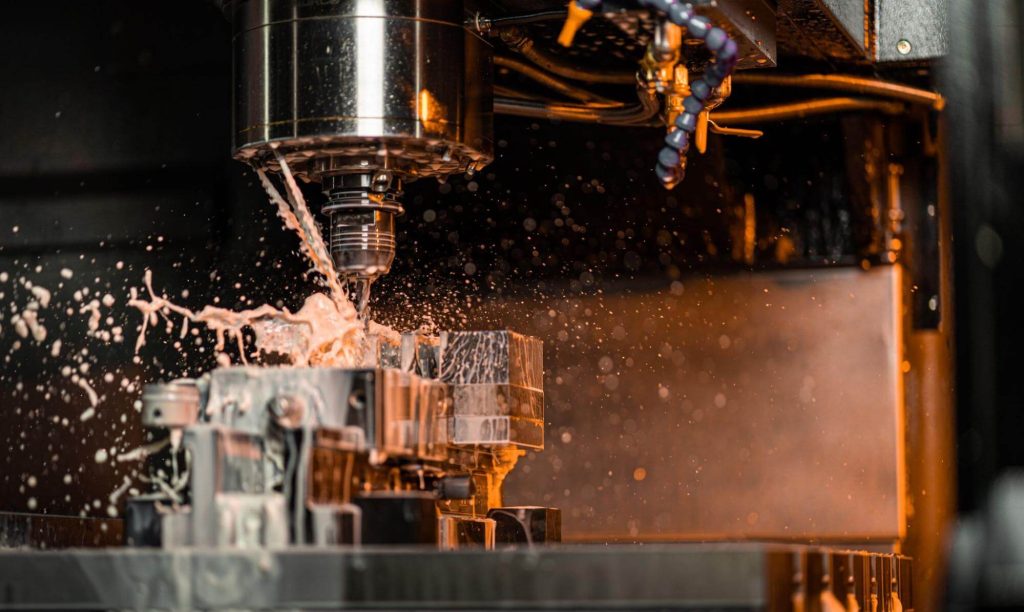

Finally, this is another frequently discussed benefit. What do I mean by a design exit ramp? I’m referring to the design freedom that 3D printing enables. For example, if you’re stuck on a specific design and reach a point where machining your part seems impossible, 3D printing gives you an exit.

Product developers can create amazing part complexity, unconstrained by traditional manufacturing limits. It’s often said (though I’m unsure who first coined the phrase) that “complexity is free”—the idea that, at least in the design phase, unlimited part complexity doesn’t incur extra cost. But be cautious here: don’t design yourself into a corner. You might need to redesign or reconfigure large parts to be machinable or moldable later. So, enjoy the freedom, but do so wisely.

For more information, please contact Debaolong Seiko. You are also welcome to upload your design to Debaolong Seiko for a quote.