It’s no secret that machines generate heat. Without effective ways to remove this heat, bearings can seize, and liquids can boil. On the other hand, properly regulated machines use heat to warm our homes and workspaces, light our bulbs, and, ironically, keep our refrigerators cold. Each of these functions—and countless others—are made possible by heat exchangers—a device introduced in the late 1800s and continuously improved ever since.

How Heat Exchangers Work

As the name suggests, they operate by conducting heat between one liquid and another, where the term “liquid” is defined to include fluids or gases. They are typically separated by thin walls of metal with high thermal conductivity (such as tubes or plates); as liquids move past each other on either side of the wall, their temperature differences balance out, thus “exchanging” heat.

Some heat exchangers are passive, relying on convection to cool components. For example, a heat sink is nothing more than a series of metal fins, like the odd-looking device on top of a desktop computer’s CPU. However, aim a fan at it, and it becomes active. This is the case for most heat exchangers, which use refrigerants (or heat sources) to create temperature differentials.

Common Types of Heat Exchangers

One of the most familiar heat exchangers is the radiator, which prevents car engines from overheating. The aerospace industry uses heat exchangers to keep cabins comfortable and fuel flowing freely. Chemical producers rely on them to condense corrosive gases, and food producers would be unable to provide safe food without heat exchangers. Examples like these are endless—these critically important devices touch nearly every aspect of our daily lives.

There are numerous types of heat exchangers available. Double-pipe, shell-and-tube, scraped-surface, spiral, or helical—these are some of the most common designs, and more are constantly being invented. This is especially true given the advent of metal 3D printers, which can create complex, conformal cooling channels and significantly increase the number of walls and chambers, thereby improving heat exchanger efficiency without the risk of fluid mixing due to brazing leaks or other types of joint failures.

How Is Thermal Conductivity of Materials Measured?

Regardless of the design, selecting the right metal is crucial. Obviously, it must be thermally conductive, but depending on the application, you must consider the metal’s resistance to chemical corrosion, repeated heating and cooling, and extreme temperatures. Abusive environments such as oil and gas exploration, mining, and nuclear energy require additional consideration to find the right material match.

For less demanding applications, copper is often a favorite metal for heat exchangers. It has a thermal conductivity of 413 watts per meter Kelvin (W/mK). Aluminum follows at 237 W/mK, cartridge brass (C26000) reaches 111 W/mK, titanium at 24 W/mK, and stainless steel and nickel-based alloys (such as Inconel and Hastelloy) have values in the teens. Engineers interested in learning more about thermal conductivity should refer to ASTM Standard C177.

Comparing Metals for Heat Exchanger Applications

Thus, copper and aluminum might seem like the only viable choices for heat exchanger materials. This is not the case. First, metal behavior varies with temperature—thermal conductivity increases as temperature rises (and vice versa). Designers should ensure they understand the operating conditions of the heat exchanger when selecting which metal to use.

More importantly for industrial applications is the metal’s strength and corrosion resistance. Copper and aluminum are too fragile for many of the harsh industrial environments listed earlier, making stainless steel and high-temperature alloys the preferred choices. Titanium, though not highly conductive, is excellent for many aerospace applications due to its superior strength and light weight, despite costing more than competing metals.

A good resource for learning more about heat exchanger design and standards is the Tubular Exchanger Manufacturers Association (TEMA) or ASME’s Boiler and Pressure Vessel Code.

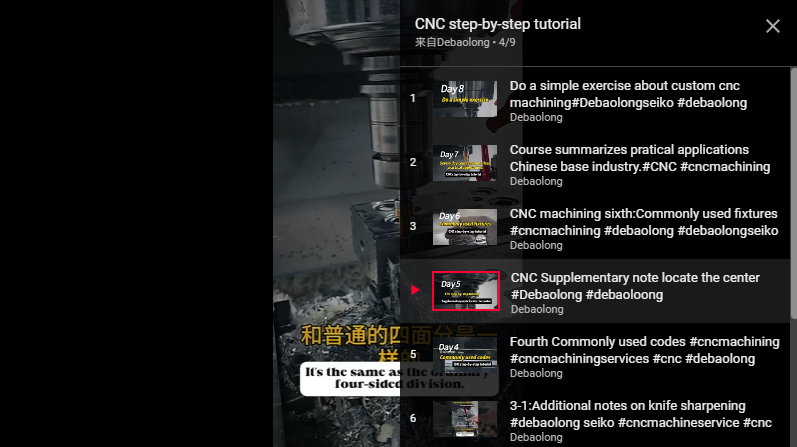

For more information, please contact Debaolong Seiko. You are also welcome to upload your design to Debaolong Seiko for a quote.