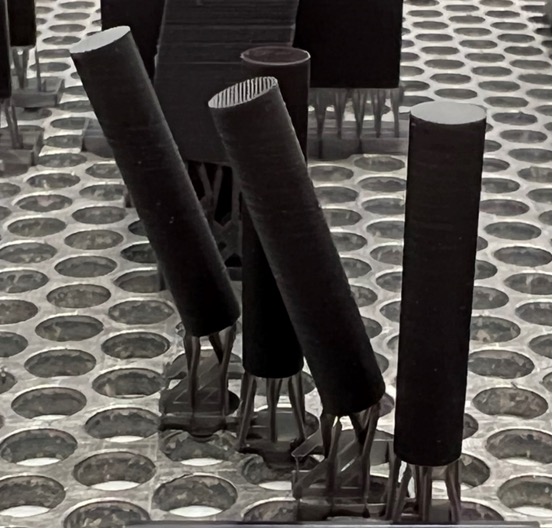

Choosing an orientation that minimizes z-height to reduce build time may seem like a no-brainer. However, when it comes to part requirements, orienting solely for z-height may not always be the most logical choice. Several technical factors come into play when considering part orientation for 3D printing—especially for stereolithography (SLA). To illustrate, think of a pencil: What would it take to 3D print this pencil layer by layer, either horizontally or vertically? Printing it horizontally would be faster because it lies flatter, while vertical printing would take longer due to its height, requiring more layers stacked sequentially. Horizontal printing also demands more support structures, which take extra time to remove for the finished part. Thus, your orientation choice may boil down to the pencil’s strength or surface finish requirements—or you might even orient the part at an angle. Let’s explore the key factors for selecting SLA build orientations.

3D Printing Part Orientation for Enhanced Strength

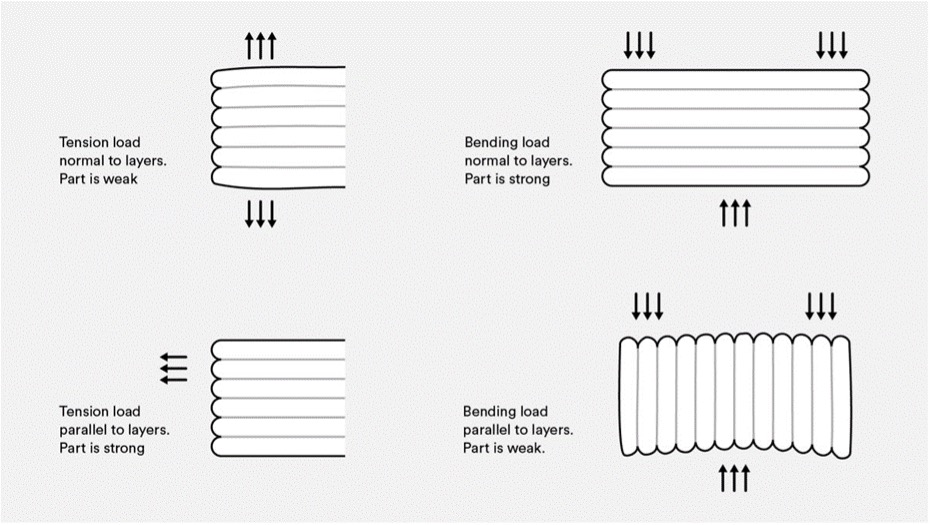

First, let’s consider a simple illustration explaining how 3D printed layer stacking and external forces affect part performance. Parts tend to be weaker when tension acts perpendicular (vertical) to the layers. They are stronger when tension is parallel (aligned) to the layers. Similarly, parts typically withstand more compression when forces act perpendicular to the layers than when forces align with them. Two key takeaways:

- Orient the part so layers align with the axis of highest tension.

- Orient the part so layers intersect with the axis of highest compression.

In the theoretical pencil example, a horizontal build orientation might account for the tension and bending forces the pencil encounters during use. Note that these guidelines always apply to fused deposition modeling (FDM) parts. SLA parts exhibit far less anisotropy than FDM parts because layers are chemically bonded, and SLA achieves much higher resolution than FDM. However, thermoset materials may still require additional consideration of part orientation to maximize strength in critical features.

Orientation to Avoid Differential Shrinkage

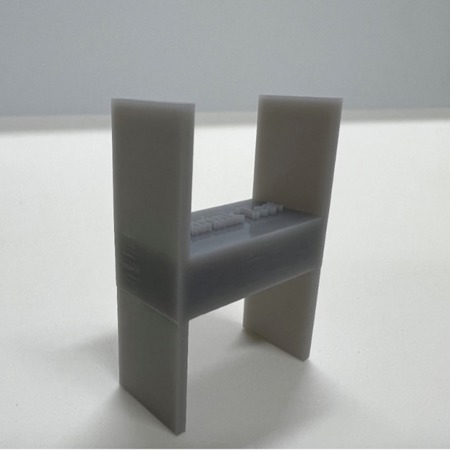

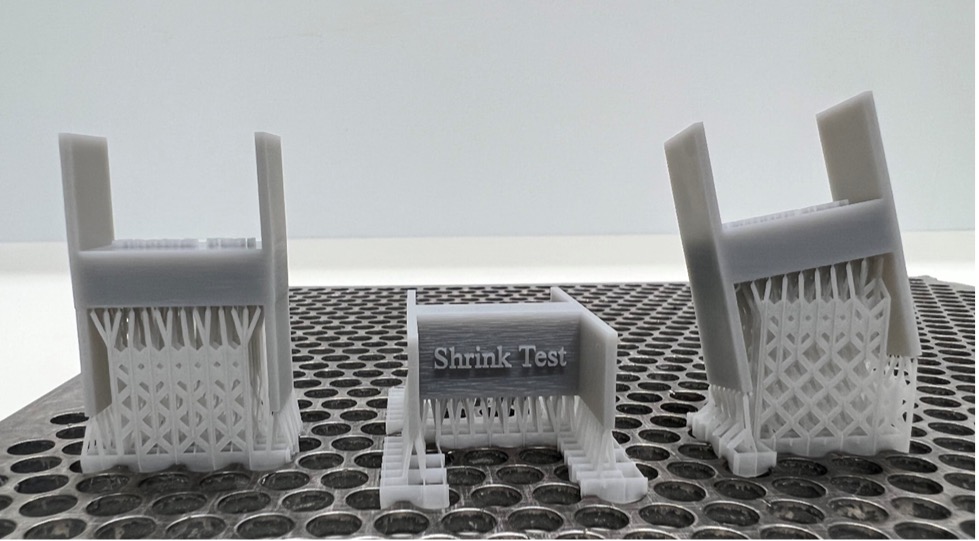

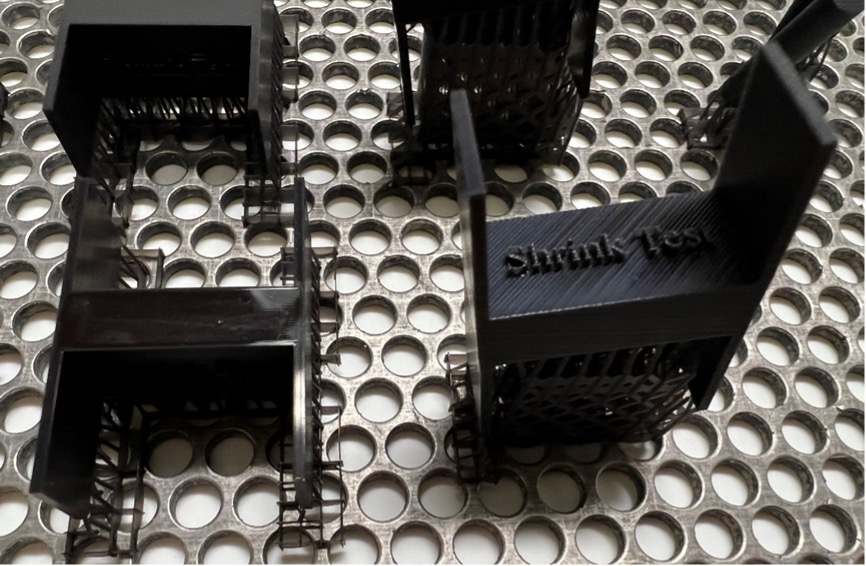

In general, the more uneven the material distribution in a part, the more susceptible it is to a phenomenon called differential shrinkage. Certain part geometries and dimensions are inherently prone to shrinking because they lack sufficient support from previous layers. To illustrate, consider a capital “H.” As the horizontal bars emerge layer by layer in the middle, they tend to pull the supporting legs inward, causing the part to bend near the base.

To prevent differential shrinkage, several strategies exist. For SLA parts, we often build them at an angle to reduce surface area, thereby minimizing overall stress encountered in each layer. This also helps improve dimensional accuracy and tolerance precision. Additionally, we may lay parts flat so that each new layer has the same surface area as the layer below it, with no large cross-sectional swings.

For dimensionally critical or high-resolution features, we recommend orienting the part to position these features on the upward-facing surface. Keep in mind, however, that building parts at an angle may compromise surface finish if cosmetics are critical.

Orientation for Desired Surface Finish

If your part requires a polished appearance—for trade shows or displays—we prefer to build it flat rather than at an angle. Critical features should face upward, as the top surface will be smoother and easier to achieve dimensional precision. Conversely, building parts face-down requires removing support structures (often via sandblasting), which can eliminate any glossy effects.

As a rule, our team may select different orientations to deliver the highest-quality part. Importantly, if you do not specify a preferred orientation (horizontal vs. vertical), we will automatically choose the one that minimizes build time. Letting us know which aspects matter most for your 3D printed part—strength, surface finish, or speed—helps us determine the optimal orientation during the build process.

For more information, please contact Debaolong Seiko. You are also welcome to upload your design to Debaolong Seiko for a quote.