3D printing, also known as additive manufacturing, has long been recognized for its prototyping capabilities. But can it also be used for mass production? The answer is yes—recent advancements have enabled 3D printing to transition into large-scale manufacturing. However, it’s worth noting that it may not always be the optimal choice.

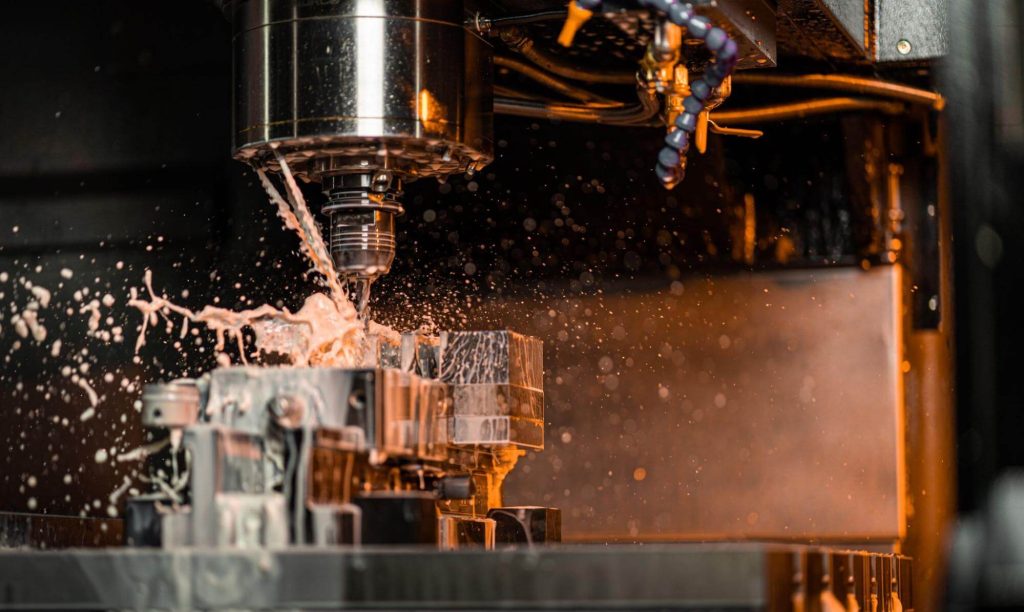

This shift toward mass production is driven by innovations that address the traditional limitations of 3D printing, such as slow production speeds, high costs, and material restrictions. As companies seek more agile and cost-effective manufacturing solutions, 3D printing is emerging as a viable alternative to traditional methods like injection molding, CNC machining, and die casting.

If you’re considering scaling up 3D-printed parts for mass production, it’s crucial to evaluate the advantages and limitations of 3D printing to determine if it fits your production needs. This article will help you assess the evolution of 3D printing in large-scale production, compare it with traditional manufacturing technologies, and explore real-world applications that highlight its strengths and challenges.

How 3D Printing Scales for Mass Production

Traditionally, 3D printing faced limitations that hindered its use in mass production. These included slow production speeds, high per-part costs, manufacturing constraints, and limited material options, making the process less viable than traditional methods.

However, recent advancements are overcoming these challenges, making 3D printing more scalable. Technologies such as Carbon’s Digital Light Synthesis (DLS), HP Multi Jet Fusion (MJF), and Selective Laser Sintering (SLS) have significantly increased printing speeds. Meanwhile, automated 3D printing farms enable continuous production, reducing downtime and improving efficiency.

Additionally, the development of improved materials has enhanced the strength, heat resistance, and overall functionality of 3D-printed parts, solidifying the technology as a competitive option for large-scale manufacturing.

Mass-Production 3D Printing vs. Traditional Large-Scale Manufacturing Methods

While 3D printing offers advantages in setup costs and small-batch production, it struggles to compete with other traditional manufacturing methods in terms of per-part price for mass production. Table 1 below compares 3D printing for production with other traditional methods:

| Factor | 3D Printing | Injection Molding | CNC Machining | Die Casting |

|---|---|---|---|---|

| Setup Costs | Low (no tooling) | High (requires tooling) | Medium | High |

| Unit Cost | High for large volumes | Low | Medium to high | Low |

| Part Production Speed | Moderate | Fast | Slow | Fast |

| Material Options | Expanding | Extensive | Extensive | Limited |

| Best For | Low-to-medium volumes, complex parts, on-demand production | High-volume standardized parts | Precision metal parts | High-volume metal parts with thin features |

Table 1: 3D Printing vs. Injection Molding, CNC Machining, and Die Casting

Advantages of 3D Printing for Mass Production

No Mold Costs and Faster Iteration

Traditional injection molding requires upfront mold investment, which can be costly, and manufacturing lead times can take weeks to months. 3D printing production eliminates the need for tooling, enabling rapid product development and helping manufacturers stay competitive in their markets. However, it’s worth noting that there are common misconceptions in the comparison between injection molding and 3D printing.

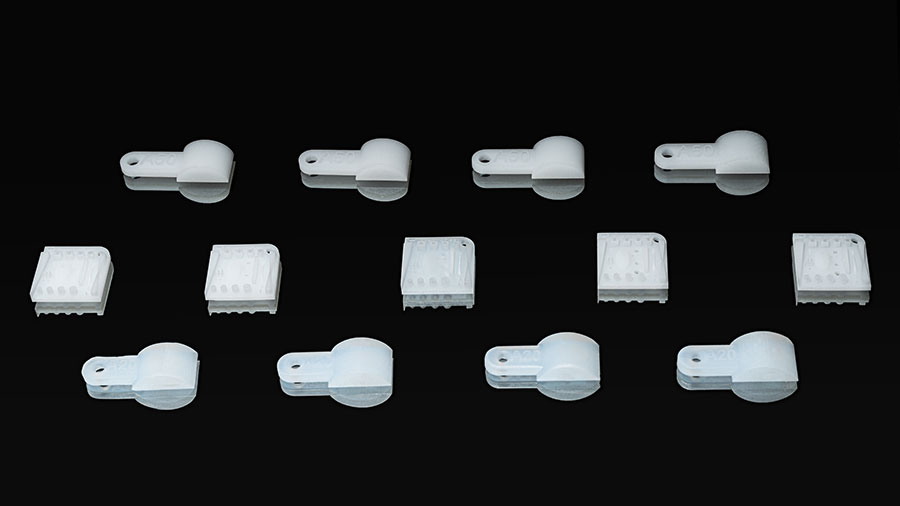

Mass Customization

3D printing can create unique products without incurring the additional costs typically associated with traditional manufacturing methods, such as tooling, labor for machine setup and operation. Examples of 3D-printed products include Invisalign aligners (for teeth straightening), medical implants, and customized consumer goods.

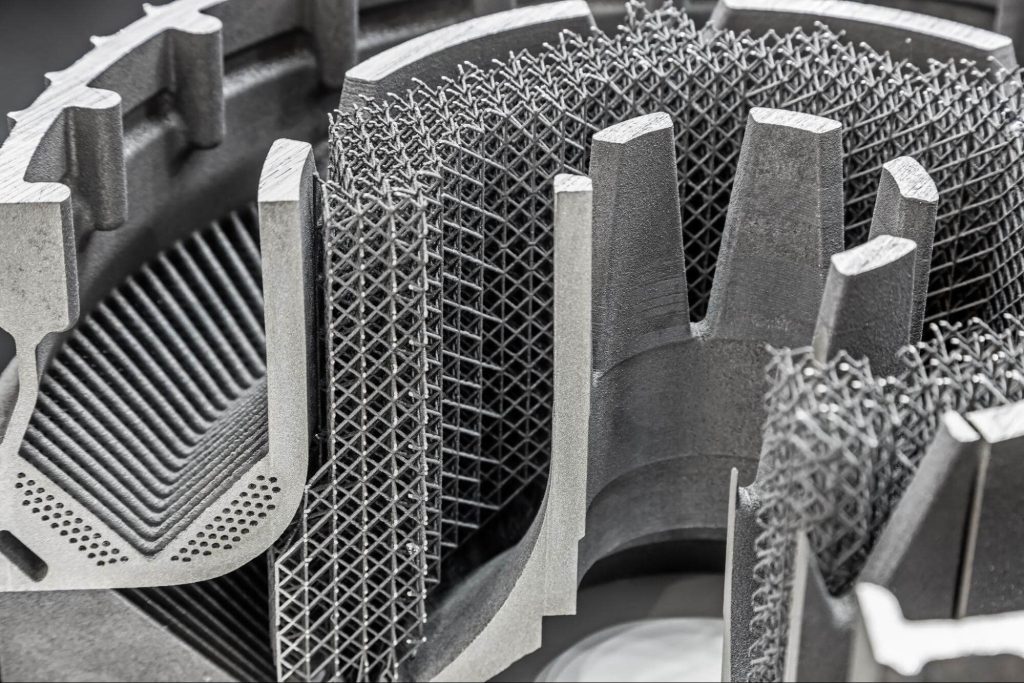

Lightweight Lattice Structures

3D printing can create stronger yet lighter designs, free from the limitations of injection molding. 3D-printed lattice structures reduce the overall weight of products while enhancing their rigidity. These properties benefit industries such as aerospace, automotive, and footwear, which require strong, lightweight products.

Challenges and Limitations of 3D Printing for Mass Production

3D printing for mass production is not without drawbacks and limitations. Below are some disadvantages of 3D printing compared to traditional methods:

Per-Part Cost vs. Injection Molding

While 3D printing is cost-effective for small to medium batches, it remains more expensive than injection molding for mass production. There is a volume threshold—sometimes as low as 500 parts—beyond which the per-part cost of 3D printing increases significantly due to material expenses and slower production speeds. In contrast, injection molding benefits from economies of scale, where high upfront mold costs are offset by extremely low unit costs for large-scale production.

Printing Speed and Throughput

A major limitation of 3D printing in production, compared to more traditional manufacturing, is its printing speed and overall throughput. Injection molding can produce thousands of parts per hour with multi-cavity molds, making it highly efficient for mass production.

In contrast, 3D printing is typically limited to batch production, where multiple parts are printed simultaneously at a much slower rate. Advancements in high-speed 3D printing technologies like Carbon’s DLS and HP Multi Jet Fusion are improving throughput, but 3D printing still lags behind traditional methods in high-volume manufacturing.

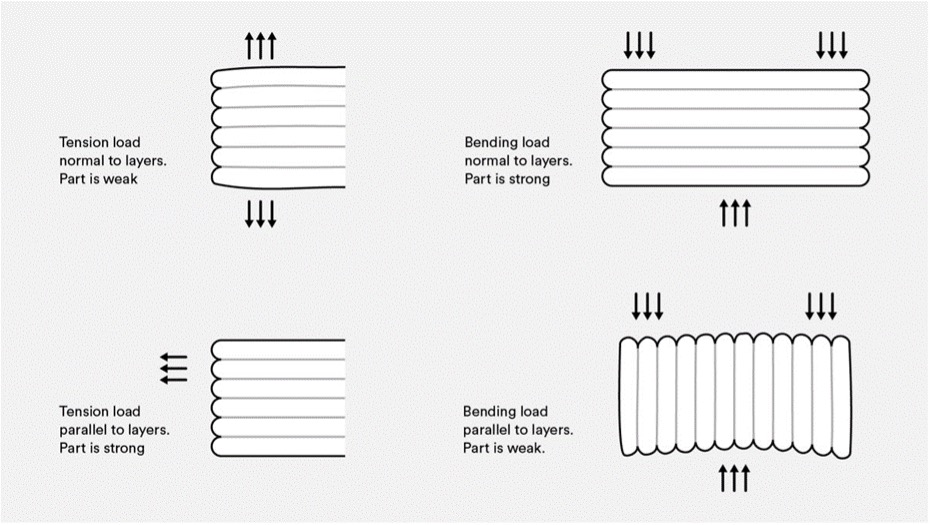

Material and Mechanical Constraints

Despite significant improvements in 3D printing materials, some 3D-printed thermoplastics still cannot match the durability, flexibility, or heat resistance of injection-molded plastics. Certain industries, such as aerospace and automotive, require materials that can withstand extreme conditions, where traditionally manufactured parts still have an advantage.

Additionally, post-processing steps such as sanding, coating, or additional curing are often needed to achieve the desired surface finish and mechanical properties, adding time and cost to the 3D printing production process.

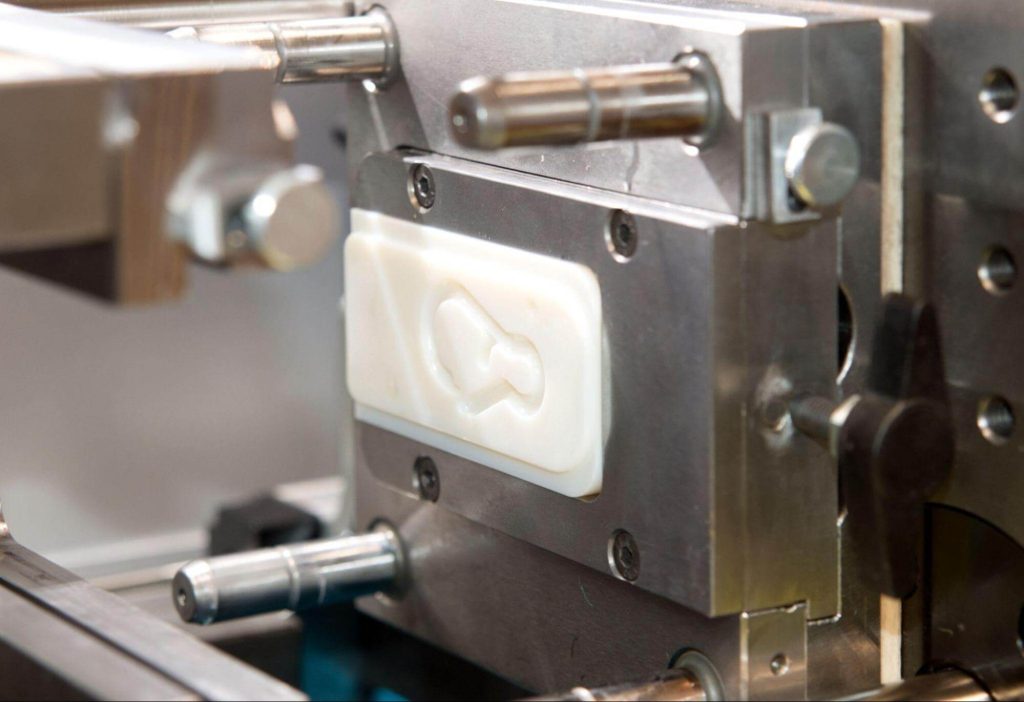

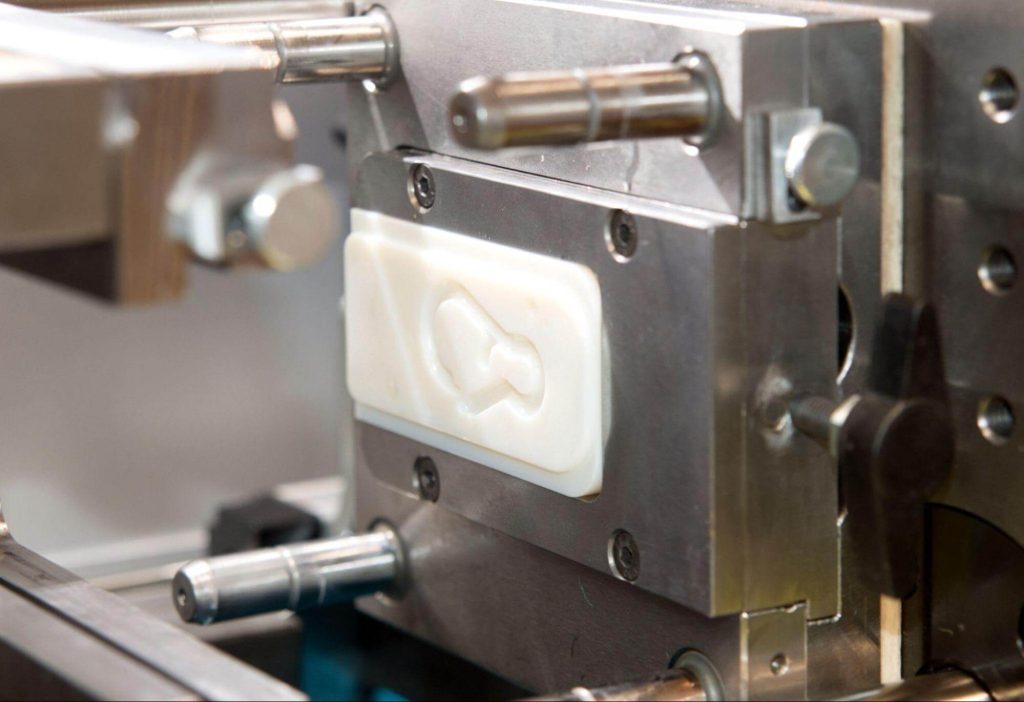

The Role of 3D-Printed Molds in Hybrid Manufacturing

3D printing also plays a crucial role in traditional manufacturing by producing molds for injection molding, thermoforming, and casting. One of the key benefits of using 3D-printed molds is the ability to quickly iterate and refine mold designs without incurring the high costs associated with traditional steel or aluminum tooling. This approach significantly reduces costs and lead times for early-stage production, making it ideal for companies looking to test designs before investing in expensive steel molds.

For low-to-medium production runs, 3D-printed molds or casts offer a cost-effective alternative to traditional methods. However, aluminum or steel molds remain the best choice for high-volume runs beyond a certain threshold due to their durability and cost efficiency at scale.

Real-World Case Study: Adidas and Carbon 3D Printing

Adidas leveraged 3D printing and Carbon’s DLS technology to mass-produce midsoles for its Futurecraft 4D shoe line, demonstrating the feasibility of 3D printing in large-scale manufacturing. With Carbon’s DLS technology, Adidas eliminated the need for expensive tooling required for traditional foam molding while significantly reducing production costs and time.

3D printing also enabled the creation of complex lattice structures to enhance performance and reduce the overall weight of the midsoles. This innovation allowed Adidas to produce over 100,000 pairs, proving that large-scale 3D printing production is achievable.

This approach has significant implications for the future of manufacturing, particularly in mass customization. 3D printing allows for unique midsoles tailored to individual athletes and accelerates design iteration without the need for new molds, streamlining the development of new product versions.

The Future of 3D Printing for Mass Production

Despite its drawbacks compared to other traditional mass production methods, 3D printing as a technology continues to evolve and advance. Here are some ways 3D printing will shape the future of mass production:

Automation and AI in Additive Manufacturing

Advancements in automation have enabled 3D printing farms to operate 24/7, significantly increasing production capacity. Additionally, AI-driven printing optimization improves efficiency by reducing material waste, optimizing print paths, and enhancing part quality. These innovations make large-scale additive manufacturing more practical and cost-effective.

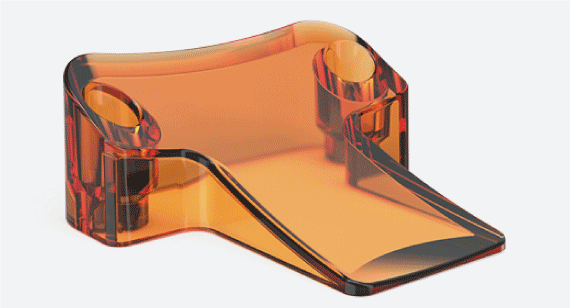

Hybrid Manufacturing: Combining 3D Printing with Injection Molding

Hybrid manufacturing is emerging as a viable approach that leverages the strengths of both 3D printing and traditional manufacturing methods. For example, 3D printing is ideal for creating complex geometries that are difficult or costly to achieve with traditional processes, while injection molding remains optimal for high-volume production of standardized parts.

3D printing can be used in production for practical applications, such as shoe soles.

The Future of 3D Printing for Mass Production

While 3D printing has drawbacks compared to other traditional mass production methods, the technology continues to evolve and advance. Here are some ways 3D printing will shape the future of mass production:

Automation and AI in Additive Manufacturing

Advancements in automation have enabled 3D printing farms to operate 24/7, significantly increasing production capacity. Additionally, AI-driven printing optimization improves efficiency by reducing material waste, optimizing print paths, and enhancing part quality. These innovations make large-scale additive manufacturing more practical and cost-effective.

Hybrid Manufacturing: Combining 3D Printing with Injection Molding

Hybrid manufacturing is emerging as a viable approach that leverages the strengths of both 3D printing and traditional manufacturing methods. For example, 3D printing is ideal for creating complex geometries that are difficult or costly to achieve with traditional processes, while injection molding remains optimal for high-volume production of standardized parts.

Can 3D Printing Replace Traditional Mass Production Methods?

While 3D printing has drawbacks compared to other traditional mass production methods, it has proven viable for small to medium production runs. Injection molding and die casting still dominate in efficiently producing large quantities of identical parts.

However, hybrid manufacturing, which combines 3D printing with traditional technologies, offers the best of both worlds. Moreover, 3D-printed molds are bridging the gap between prototyping and full-scale production, making manufacturing more agile and cost-effective. Businesses looking to scale production should consider leveraging 3D printing where it provides a competitive advantage.

For more information, contact Debaolong Seiko. You are also welcome to upload your designs to Debaolong Seiko for a quote.