Metal part manufacturing is the process of shaping, cutting, and assembling metal materials into components used across countless industries. Its importance lies in its ability to produce durable, precise, and high-performance parts that meet the demanding requirements of modern technology and infrastructure.

This article reviews all key metal part manufacturing processes, from large components to small, complex parts. We will cover CNC machining, casting, forging, metal injection molding, metal 3D printing, and sheet metal fabrication. It explains the advantages of each process, the materials used, and the factors to consider when selecting them.

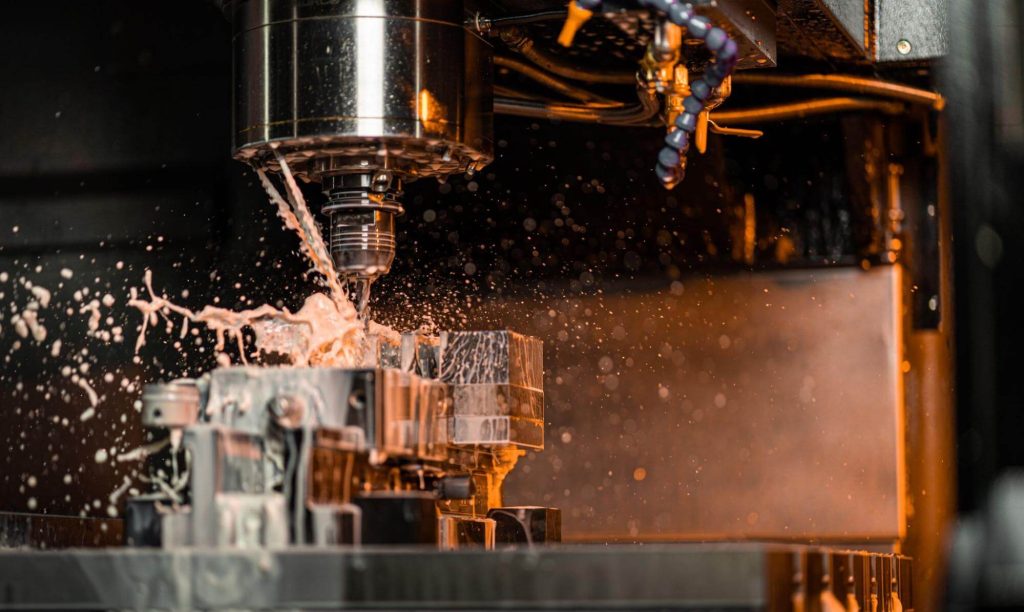

CNC Machining for Precision Metal Parts

CNC (Computer Numerical Control) machining is a subtractive manufacturing process where computer-controlled cutting tools remove material from a solid billet (block) to produce finished parts. This method is widely used in metalworking to create high-precision components with tight tolerances.

CNC machining supports a variety of materials, including aluminum, steel, titanium, and brass, each chosen based on specific properties such as strength, durability, and corrosion resistance.

CNC machining is known for its high precision and versatility, working with both metals and plastics. It is suitable for prototyping and small to medium production runs. This method offers excellent scalability and flexibility, making it ideal for meeting diverse manufacturing needs.

A notable advantage is its ability to consistently produce parts with very tight tolerances and precise dimensions. This method can accommodate complex geometries, albeit with some limitations, making it suitable for most engineering applications.

Sheet Metal Cutting and Stamping

Sheet metal cutting and stamping are used to form thin metal sheets into highly functional parts. Various techniques cut, bend, and shape sheet metal with exceptional precision and repeatability, including:

- Laser cutting: Uses a high-power laser beam to create complex, high-precision designs.

- Waterjet cutting: Uses high-pressure water mixed with abrasive particles, ideal for heat-sensitive materials.

- Punching and stamping: Hardened tool steel dies are used to produce holes, cutouts, or complex 3D features in metal sheets.

Common materials include steel, stainless steel, aluminum, and copper—each selected based on its specific properties, application, and cost-effectiveness. These techniques are widely used in industries such as automotive (body panels), electronics (enclosures), and general manufacturing (brackets and structural components).

Sheet metal cutting and stamping offer numerous advantages. They are highly cost-effective, producing parts with consistent quality quickly, making them ideal for high-volume manufacturing. Additionally, they allow for complex geometries with tight tolerances, ensuring parts meet precise design specifications.

Metal Forming

Metal forming methods are a set of versatile manufacturing processes that involve bending, rolling, and pressing metal sheets, bars, or plates to create metal parts. Technologies such as press brakes, roll forming, and stamping produce a range of components, from simple bends to complex geometries. Common materials include aluminum and steel, valued for their strength and corrosion resistance.

Metal forming is particularly effective for producing structural components and enclosures requiring durability and precision. The process is widely used in industries such as construction (pipes, beams), automotive (body panels, frames), and aerospace (fuselage parts, wing components).

The advantages of metal forming are numerous. It is highly cost-effective, enabling rapid production of parts with consistent quality, making it ideal for high-volume manufacturing. Additionally, metal forming can achieve complex net shapes with tight tolerances, ensuring parts meet exact design specifications.

Metal Casting

Metal casting is one of the oldest and most fundamental manufacturing methods. In this process, molten metal is poured into a mold cavity to form complex shapes and components. Over time, it has evolved into various techniques:

- Die casting: Uses high pressure to produce precision parts in aluminum and zinc alloys, ideal for high-volume production and complex or thin-walled features. Learn more from our die casting design guide.

- Investment casting (also known as lost-wax casting): The process begins by shaping the part in wax, which is then encased in a refractory ceramic shell. Once the shell hardens, the wax is removed by heating, leaving a precise mold cavity. This method produces highly complex, precision parts with smooth surface finishes, making it ideal for aerospace and medical applications.

- Sand casting: Best suited for large parts, such as industrial machinery and automotive components, often used for small to medium production runs.

Metal castings are used in industries such as automotive (engine blocks, transmissions), aerospace (turbine blades, structural components), and industrial machinery (pumps, valves). Its ability to produce complex geometries with minimal post-processing makes it the preferred choice for parts requiring intricate designs.

The advantages of metal casting are significant. It supports high-volume production, making it economical for large-scale manufacturing. The process is also compatible with a wide range of metals, offering flexibility in material selection. Additionally, casting can produce near-net-shape parts, reducing material waste and machining requirements. Combining versatility, precision, and scalability, metal casting remains a cornerstone of modern manufacturing.

Forging

Forging is a manufacturing process that shapes metal using compressive force. This force is typically applied through hammering and pressing, often in combination with precision dies.

This method aligns the metal’s grain structure with the shape of the finished part, enhancing its strength, durability, and resistance to impact and fatigue. Common materials used in forging include most steels, titanium, and brass, chosen for their ability to withstand high stress and environmental conditions.

Forged components are critical in demanding industries requiring parts that can withstand high loads, fatigue, and harsh environments, such as aerospace (landing gear, engine parts), oil and gas (valves, drill bits), and heavy machinery (crankshafts and gears).

Forging enhances a part’s mechanical properties by aligning the metal’s grain structure through controlled compression. This directional grain flow improves tensile strength, fatigue resistance, and overall structural integrity, making it ideal for high-performance applications.

Forged parts also exhibit high durability and reliability, reducing the risk of failure in critical applications. Additionally, forging can achieve precise, near-net shapes while minimizing material waste, making it efficient and cost-effective for high-performance parts.

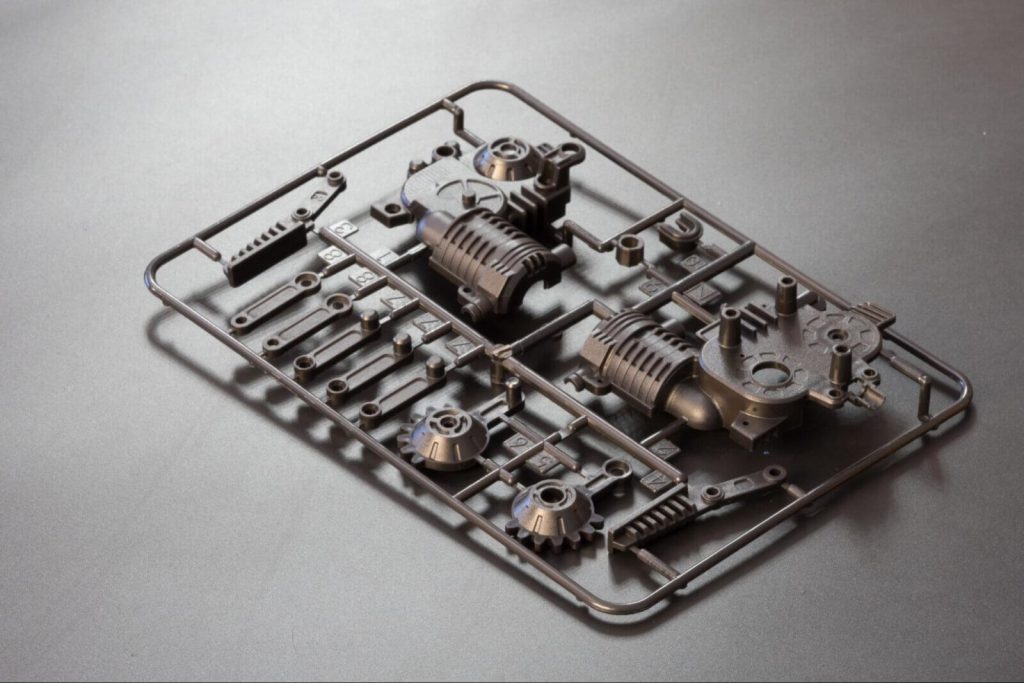

Metal Injection Molding (MIM)

Metal injection molding (MIM) is an advanced manufacturing process ideal for producing small, complex metal components. It combines the versatility of plastic injection molding with the durability of metal.

The process begins by mixing fine metal powder with a polymer binder to form a moldable feedstock. This mixture is injected into a mold to form the desired shape. The molded part undergoes debinding and sintering at high temperatures to achieve its final density and strength. During this process, the binder is burned off, causing the oversized molded part to shrink to its intended dimensions as metal particles fuse together, resulting in 100% density.

Common materials used in MIM include stainless steel and nickel alloys, known for their corrosion resistance and durability. The process is ideal for small, complex parts requiring tight tolerances. Industries such as electrical products, automotive, and consumer electronics use MIM to produce complex, high-precision components.

MIM excels at creating highly detailed, near-net-shape components that would be difficult or costly to produce using traditional methods. This includes high-quality surface finishes, minimizing post-processing. The process is also highly scalable, making it cost-effective for large-scale production. Additionally, MIM offers excellent material utilization, reducing waste and lowering overall costs.

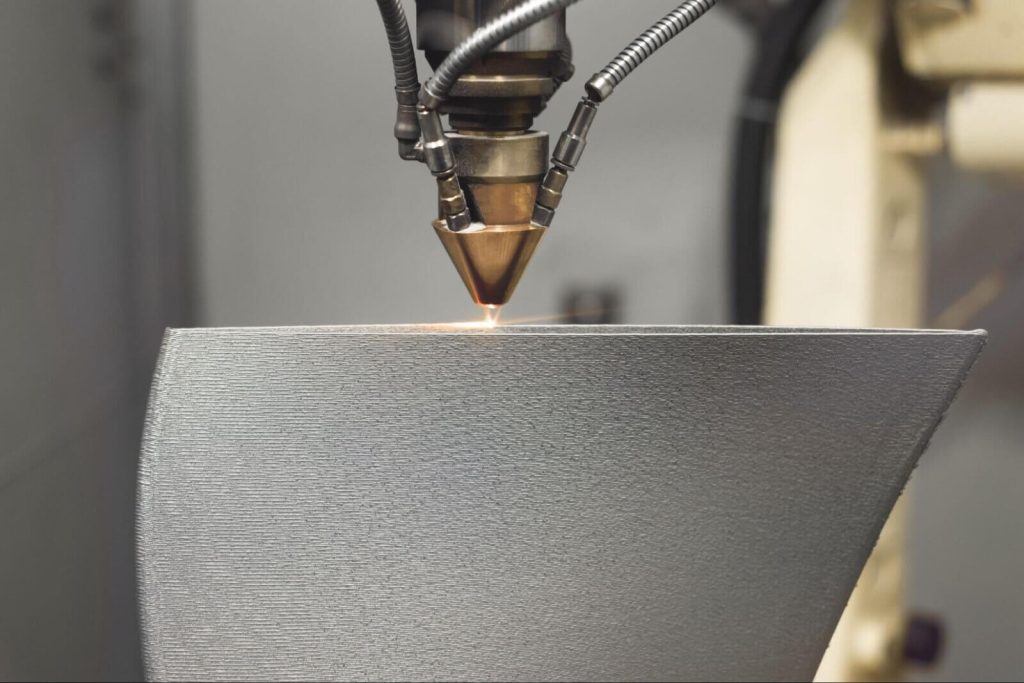

Metal 3D Printing

Metal 3D printing, also known as metal additive manufacturing, is a cutting-edge process that builds parts layer by layer from metal powder using high-energy sources such as lasers or electron beams. This technology enables the creation of highly complex and lightweight geometries that are difficult or impossible to achieve with traditional manufacturing methods.

Common methods include:

- Selective Laser Melting (SLM) and Direct Metal Laser Sintering (DMLS): Use lasers to fully or partially melt metal powder and fuse it together.

- Electron Beam Melting (EBM): Similar to SLM but uses an electron beam in a vacuum, suitable for high-temperature materials like titanium.

- Binder Jetting: Involves depositing a binder onto a powder bed, followed by sintering—ideal for high-volume, low-cost metal part production.

Common materials used in metal 3D printing include stainless steel, titanium, aluminum, cobalt-chromium alloys, and Inconel, chosen for their mechanical strength, corrosion resistance, and temperature tolerance.

Metal 3D printing is widely used in industries such as aerospace (lightweight structural parts), medical (custom implants and surgical tools), and automotive (prototyping and motorsport components). It can consolidate multi-part assemblies into a single piece, reducing assembly steps and improving performance.

The key advantages of metal 3D printing include exceptional design freedom, low material waste, and rapid prototyping of high-performance parts. The process also supports true near-net-shape manufacturing, reducing or eliminating the need for secondary machining. Additionally, metal additive manufacturing excels at producing custom or low-volume parts quickly, making it ideal for innovation-driven applications and high-mix, low-volume production environments.

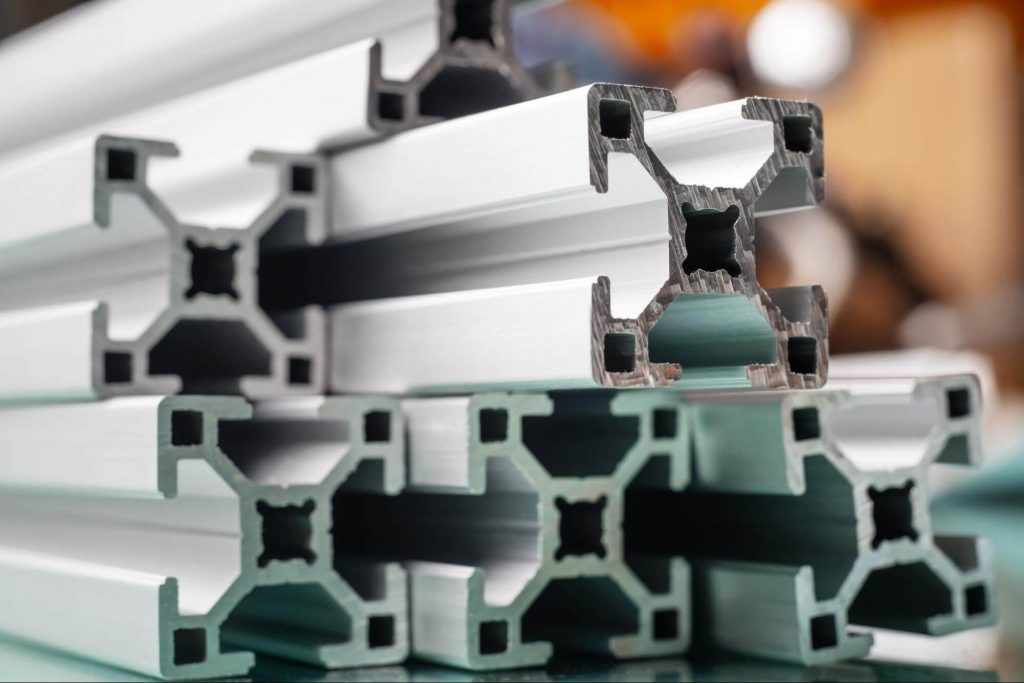

Metal Extrusion

Metal extrusion is a manufacturing process where heated metal is forced through a die to create parts with uniform cross-sections. This method is particularly effective for producing long, continuous shapes such as rods, bars, and tubes. Common metals used in extrusion include aluminum, copper, and magnesium, chosen for their lightweight properties, strength, and conductivity.

The process is widely used in industries such as electronics (heat sinks, connectors), construction (structural frames, window profiles), and automotive (pipes, chassis components). Extruded parts are valued for their consistency, precision, and ability to meet complex design requirements.

Metal extrusion is ideal for manufacturing lightweight, high-strength parts, making it a preferred choice for applications where weight reduction is critical. The process also offers excellent material utilization, minimizing waste and allowing for scrap recycling. Additionally, extrusion supports the production of complex cross-sections with tight tolerances, ensuring high-quality results.

Welding in Metal Manufacturing

Welding is one of the most critical metal part manufacturing processes, involving joining metal components using high heat, often with the addition of compatible filler material. This creates a permanent bond, ensuring structural integrity and resilience/strength. Common welding techniques include:

- MIG (Metal Inert Gas): Also known as Gas Metal Arc Welding (GMAW), uses a consumable wire electrode and shielding gas delivered through a welding gun. It is fast, relatively easy to learn, and produces strong, clean welds, making it ideal for steel, aluminum, and high-throughput manufacturing.

- TIG (Tungsten Inert Gas): Also known as Gas Tungsten Arc Welding (GTAW), uses a non-consumable tungsten electrode and a separate filler rod (if needed), along with an inert shielding gas such as argon. TIG is known for its precision and clean finishes, often used for critical welds in aerospace, marine, and precision manufacturing.

- Spot welding: A resistance welding process that joins overlapping metal sheets by applying pressure and passing high current through contact points. Unlike arc welding, it does not use electrode wire or shielding gas. It is ideal for joining sheet metal in high-volume applications such as automotive body panels and electronic enclosures.

Welding is widely used in industries such as automotive (chassis, body frames), shipbuilding (hulls, structural components), and heavy machinery (frames, attachments). Its ability to create durable, high-strength joints makes it indispensable for building large, complex structures.

The advantages of welding are numerous and hard to replace in custom metal part manufacturing. It provides a permanent, integral material bond, ensuring a long-lasting and reliable connection without the need for fasteners.

The process also enhances structural strength by improving stress dissipation and resistance to vibration and fatigue, making it suitable for load-bearing applications. Additionally, welding is versatile, adapting to various metals and thicknesses, and can be applied to both manual and automated production.

To maintain consistency and precision in welded assemblies, welding fixtures (specialized tools that hold parts in place during welding) are often used to ensure accurate alignment and maintain critical specifications throughout production.

Choosing the Right Metal Part Manufacturing Process

Selecting the appropriate manufacturing process for metal parts is a critical decision that impacts quality, cost, and production timelines. Table 1 compares key differences between various metal part manufacturing methods:

| Process | Materials | Production Volume | Typical Tolerances (mm) | Surface Quality | Cost | Example Applications |

|---|---|---|---|---|---|---|

| Casting | Aluminum, iron, bronze, zinc | Low–High | 0.5–2.0 | Medium-rough | Low–Medium | Engine blocks, tool structures, pipes, sculptures |

| Forging | Steel, aluminum, titanium | Medium–High | 0.3–1.0 | Medium | Medium–High | Crankshafts, gears, aerospace parts |

| Machining | All metals | Low–High | 0.025–0.1 | Very smooth | High | Precision parts, tools, prototypes |

| Sheet metal forming | Steel, aluminum, copper | Medium–High | 0.1–0.5 | Smooth | Low–Medium | Automotive panels, enclosures, electrical appliances |

| Metal 3D printing | Steel, aluminum, titanium | Medium–Low | 0.1–0.5 | Medium-rough | High | Aerospace, medical implants, lightweight structures |

| Extrusion | Aluminum, copper, soft alloys | High | 0.1–0.5 | Smooth | Low–Medium | Window frames, rods, tubes |

| Metal injection molding | Steel, titanium, tungsten | High | 0.1–0.3 | Medium | Medium | Gears, bearings, filters |

| Welding | Most metals | Varies by skill/equipment | 0.5–3.0 | Rough | Variable | Pipes, shipbuilding, machinery |

Optimizing Metal Fabrication: Choosing the Right Method for Superior Results

Metal fabrication offers a variety of manufacturing methods with unique advantages and applications. From casting and forging to machining and welding, selecting the right technique depends on factors such as material properties, precision requirements, production volume, and cost efficiency. For example, casting is ideal for complex shapes, while forging provides superior strength. Machining ensures high precision, and welding enables strong connections.

As technology evolves, staying informed about these processes helps optimize production quality and efficiency. We encourage manufacturers and engineers to carefully evaluate their project needs—considering materials, design complexity, and budget—to select the most appropriate method. By doing so, businesses can enhance performance, reduce waste, and achieve better results in metal fabrication projects.

For more information, please contact Debaolong Seiko. You are also welcome to upload your design to Debaolong Seiko for a quote.