If so, various bridge production methods can help you increase output. You may have heard of 3D printing for prototyping and injection molding for production, but you might not know about using them together. 3D printing can provide on-demand molds, especially for small-batch mold production.

Traditional mold manufacturing methods, such as those used for injection molding and thermoforming, typically have high upfront costs and long lead times, making them less suitable for small-batch production or rapid prototyping. These methods are often more expensive and require the creation of complex molds, which can take longer to manufacture.

By leveraging additive manufacturing for molds, the time and cost of producing 3D-printed molds are only a fraction of those of traditional molds. For small-batch production, this gives it a clear advantage over traditional mold manufacturing, which can be slower and more costly. As a result, manufacturers can now quickly create prototypes, iterate on designs, and bring products to market faster than ever before, without the financial commitment of traditional tooling.

What Are 3D-Printed Molds?

3D-printed molds are produced using additive manufacturing technologies, such as SLA (Stereolithography), FDM (Fused Deposition Modeling), SLS (Selective Laser Sintering), and even metal 3D printing processes like DMLS (Direct Metal Laser Sintering).

Unlike traditional tooling, which relies on CNC machining or casting methods, 3D-printed molds are created by precisely laying down layers of material, offering designers greater flexibility in mold design and production.

Types of 3D-Printed Molds

Different types of molds are suited to specific applications, and 3D printing enables the manufacturing of molds for various production processes. Common types include:

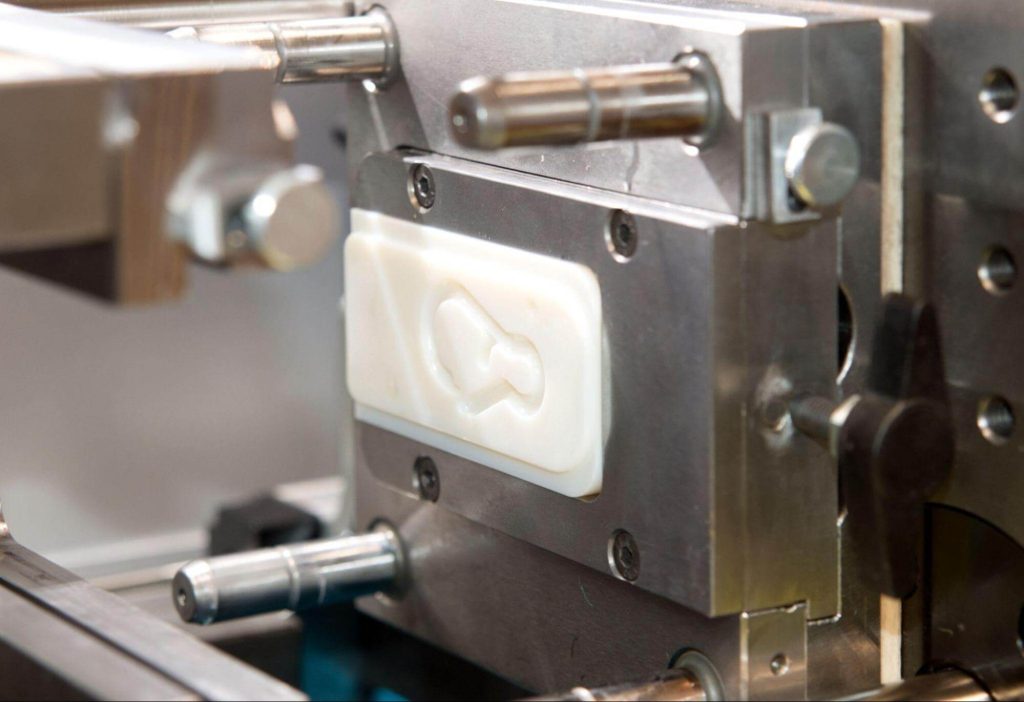

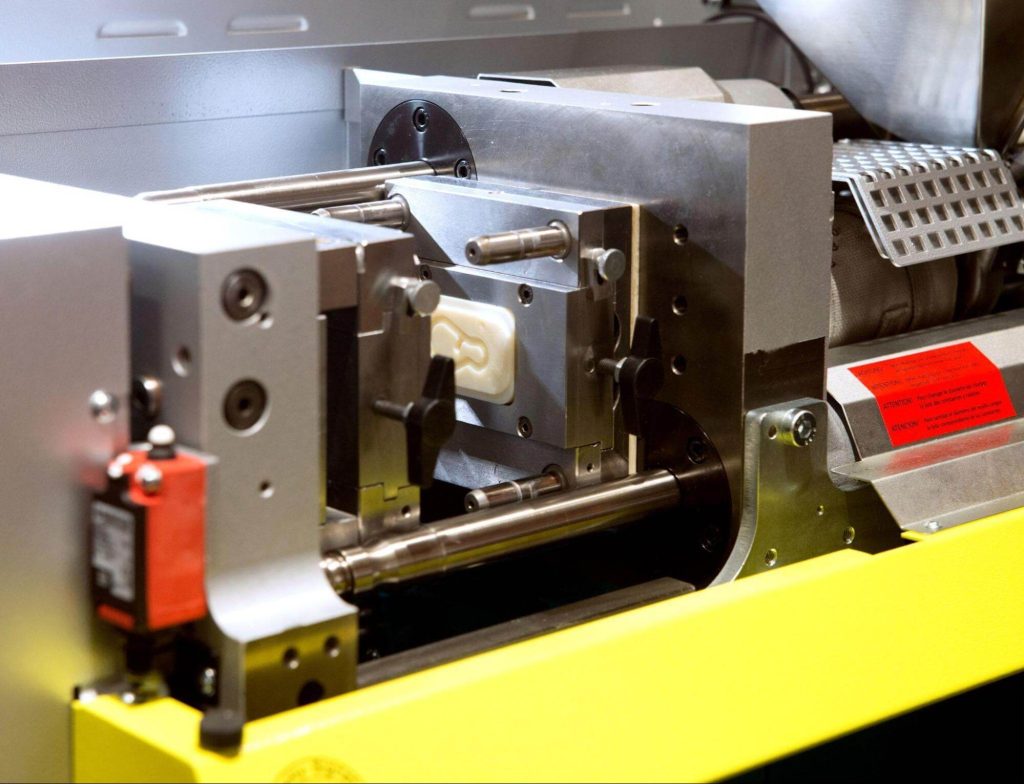

- Injection Molds (for plastics):

3D-printed inserts provide a cheaper and faster alternative to traditional steel molds. They are ideal for small-batch production, prototyping, and low-volume manufacturing, enabling the creation of complex geometries with shorter lead times. - Polyurethane Casting Molds (for flexible and rigid materials):

These molds are used to produce flexible and rigid parts, allowing liquid polyurethane to cure within them. They offer a cost-effective solution for small-batch production and prototyping, supporting a range of material hardness levels. - Thermoforming Molds (for packaging and consumer goods):

Designed specifically for shaping thermoplastic sheets, they are widely used in small-batch production of packaging, medical trays, and consumer goods. With fast turnaround times and cost efficiency, they are ideal for prototyping and low-volume manufacturing. - Mantle3D (metal inserts):

Metal slurry layers are added using slurry deposition technology, then processed and hardened in a high-temperature furnace. This creates 3D-printed inserts with performance and durability that surpass traditional 3D printing.

Materials Used in 3D-Printed Molds

Materials used in 3D-printed molds can vary significantly depending on the mold type and the requirements of the production process. The most commonly used materials are:

- Resin Molds (SLA/DLP printers):

Resin molds made using SLA or DLP technology offer high detail, smooth surfaces, and heat resistance. They are well-suited for small-batch injection molding and polyurethane casting, where precision and durability are crucial. - Polymer Molds (SLS/FDM printers):

Polymer molds manufactured using SLS or FDM are cost-effective and ideal for small to medium batch production. While their heat resistance is not as high as that of resin or metal molds, they offer versatility with materials like nylon and PLA, making them suitable for thermoforming and polyurethane casting. - Metal 3D-Printed Molds (Mantle3D, DMLS/SLM printers):

Metal molds made using Mantle3D, DMLS, or SLM are durable and heat-resistant, making them ideal for high-temperature, high-volume production. They offer excellent strength, wear resistance, and longevity, suitable for extended production runs.

3D-Printed Molds vs. Traditional Injection Molding Methods

Table 1 shows the differences between 3D-printed molds and traditional mold manufacturing methods:

| Factor | 3D-Printed Molds | Traditional Metal Molds |

|---|---|---|

| Setup Costs | Low | High (requires tooling) |

| Lead Time | Days to weeks | Weeks to months |

| Unit Cost | Higher at high volumes | Lower at high volumes |

| Design Iterations | Easy, rapid changes | More expensive, slower changes |

| Durability | Suitable for short runs (10–1,000 cycles) | Ideal for high-volume production |

| Best For | Prototyping, small to medium batches | High-volume production (250–10,000+ cycles) |

Table 1: Comparison of 3D-Printed vs. Traditional Mold Manufacturing Methods

Advantages of 3D-Printed Molds

Using 3D-printed molds offers the following benefits:

- Faster Iteration and Design Changes: 3D printing allows designers to quickly modify and produce new mold designs in days rather than weeks. This rapid turnaround is particularly beneficial for R&D teams that need to test multiple iterations before full-scale production.

- Reduced Costs for Small-Batch Production: By eliminating the need for expensive CNC machining and traditional mold manufacturing processes, 3D-printed molds significantly reduce costs. Additionally, they minimize material waste compared to subtractive manufacturing methods.

- On-Demand Production and Localized Manufacturing: Digital mold files can be shared and printed anywhere, eliminating the need to store expensive metal molds. This reduces supply chain risks and enables localized production.

- Hybrid Manufacturing Potential: 3D-printed mold inserts can be combined with CNC-machined mold bases, allowing manufacturers to test designs before investing in full-size metal molds. This approach provides greater flexibility and cost savings during the development process.

Limitations and Challenges of 3D-Printed Molds

While 3D-printed molds have many advantages, there are also some limitations and challenges to consider:

- Limited Lifespan for High-Volume Runs: Polymer-based 3D-printed molds wear out faster than traditional steel molds, making them best suited for producing 10 to 1,000 parts. This is a significant drawback for high-volume manufacturing.

- Material and Thermal Constraints: Some 3D-printed materials may not withstand the high injection pressures or temperatures required for specific molding processes. However, advancements in high-performance resins and metal 3D printing technologies are gradually mitigating these limitations.

- Post-Processing and Surface Finish: These molds often require additional finishing steps, such as sanding, coating, or polishing, to achieve a smooth surface. Fine details may not be as precise as with CNC machining, increasing the time and cost of the mold manufacturing process.

Best Applications for 3D-Printed Molds

Some of the best applications for 3D-printed molds include:

- Prototyping and Rapid Iteration: Ideal for testing designs before full-scale production. They support quick iterations and improvements, reducing development time and costs.

- Short-Run and Custom Manufacturing: Perfect for small-batch niche or custom products, enabling manufacturers to quickly respond to market demands and offer personalized products without high mold costs.

- Small-Batch Injection Molding: Provide a cost-effective alternative to traditional metal molds, reducing expenses and lead times for runs of 10–1,000 plastic parts.

- Medical, Aerospace, and Automotive Components: In industries requiring rapid iteration and lightweighting, they enable fast design, testing, and refinement while minimizing material waste and costs.

- Polyurethane Casting and Thermoforming: Widely used in polyurethane casting, where silicone molding is used for flexible parts. They also serve as vacuum forming molds for manufacturing packaging and consumer goods.

The Future of 3D-Printed Molds and Digital Manufacturing

The future of 3D-printed molds and digital manufacturing looks promising, with several key developments on the horizon:

- Advancements in High-Performance Materials: The development of heat-resistant SLA resins will enable these molds to withstand higher temperatures and pressures, improving their durability and lifespan. Additionally, metal 3D-printed molds may be able to replace traditional steel molds for medium-batch production, enhancing performance and cost efficiency.

- Automated 3D Printing for On-Demand Tooling: AI-driven automated mold design and production will streamline the mold manufacturing process, reducing lead times and costs. To further enhance supply chain flexibility, cloud-based digital tool storage will enable remote manufacturing, allowing companies to produce molds anywhere in the world using 3D printers.

- Hybrid Manufacturing with 3D-Printed Inserts: Combining CNC-machined mold bases with 3D-printed inserts will provide manufacturers with greater flexibility in their production processes. This hybrid approach allows for rapid design changes and cost-effective small-batch production while maintaining the durability and precision of traditional metal molds.

Is 3D-Printed Tooling Right for Your Business?

3D-printed tooling is ideal for rapid iteration, prototyping, and small to medium batch production. It enables companies to quickly test and refine designs, significantly reducing development time and costs compared to traditional metal molds.

While the technology cannot fully replace traditional metal tooling in all cases, it offers a fast and cost-effective alternative for specific applications. Businesses can efficiently produce small-batch parts without the high upfront investment typically required for traditional molds.

For those seeking flexible, on-demand manufacturing solutions, exploring additive manufacturing for mold production is recommended. It allows companies to quickly adapt to changing market demands and create custom products with shorter lead times.

Ultimately, the decision to adopt 3D-printed molds depends on factors such as production volume, design complexity, and material requirements. By carefully evaluating these aspects and consulting with experienced digital manufacturing providers like Debaolong Seiko, businesses can determine if this approach is right for their needs.

For more information, contact Debaolong Seiko. You are also welcome to upload your designs to Debaolong Seiko for a quote.