Copper is an incredible metal and element that powers the world through applications ranging from electronics to plumbing, and even serves as a coenzyme in the human body.

What Is Copper?

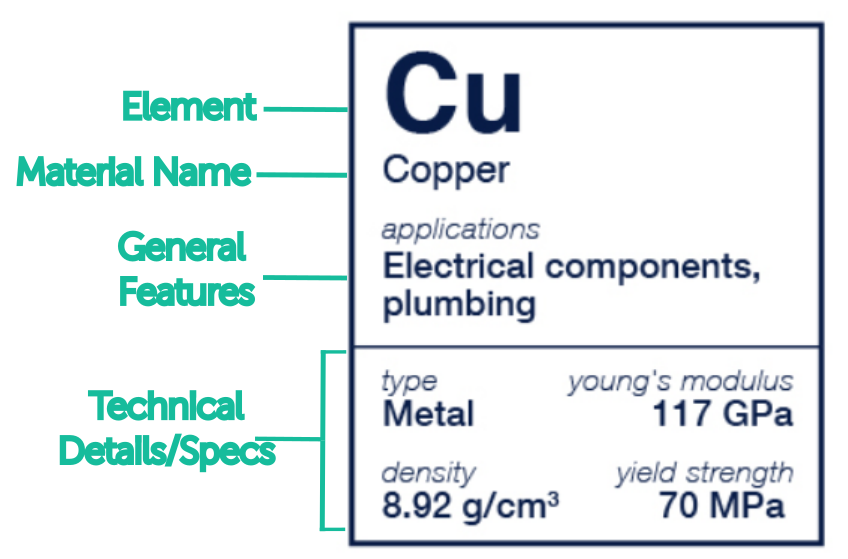

At this very moment, copper is likely powering something near you. Copper (Cu), derived from the Latin word Cuprum meaning “from Cyprus,” has been used by humans for over 8,000 years, dating back to 10,000 BCE. As one of the few metals found in nature in its pure form, copper is both versatile and essential, with applications spanning from electrical wiring to mechanical parts and water pipes.

Chemically, copper is known as cuprum on the periodic table, with an atomic number of 29. It is a reddish-nonferrous metal and one of the “transition metals” alongside silver and gold. Copper’s high electrical conductivity makes it an excellent choice for electronics. Additionally, it is malleable and ductile, allowing it to be easily formed into wires, tubes, and other shapes while retaining its mechanical strength.

Properties of Copper

When considering copper for mechanical parts and products, several factors should be 牢记:

- Type of copper or alloy

- Material cost

- Manufacturing method

- Environment in which the part or product will operate

- Strength, durability, and conductivity required for the application

Let’s explore copper’s valuable properties:

- Workability: Copper can be easily welded, brazed, or soldered to form strong, durable joints. It readily alloys with other metals to enhance strength and durability for specific applications.

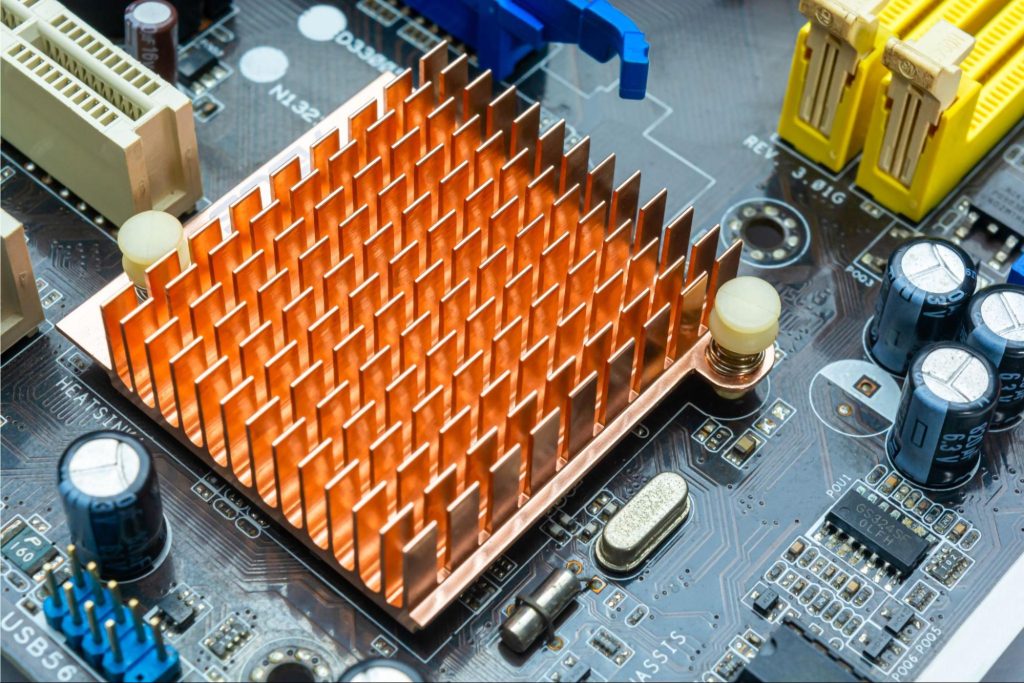

- Thermal Conductivity: Copper’s applications in mechanical parts often stem from its heat-dissipating ability. With a higher thermal conductivity than other metals of similar strength, it is ideal for heat exchangers like radiators. This property improves efficiency and reduces overheating risks in mechanical systems.

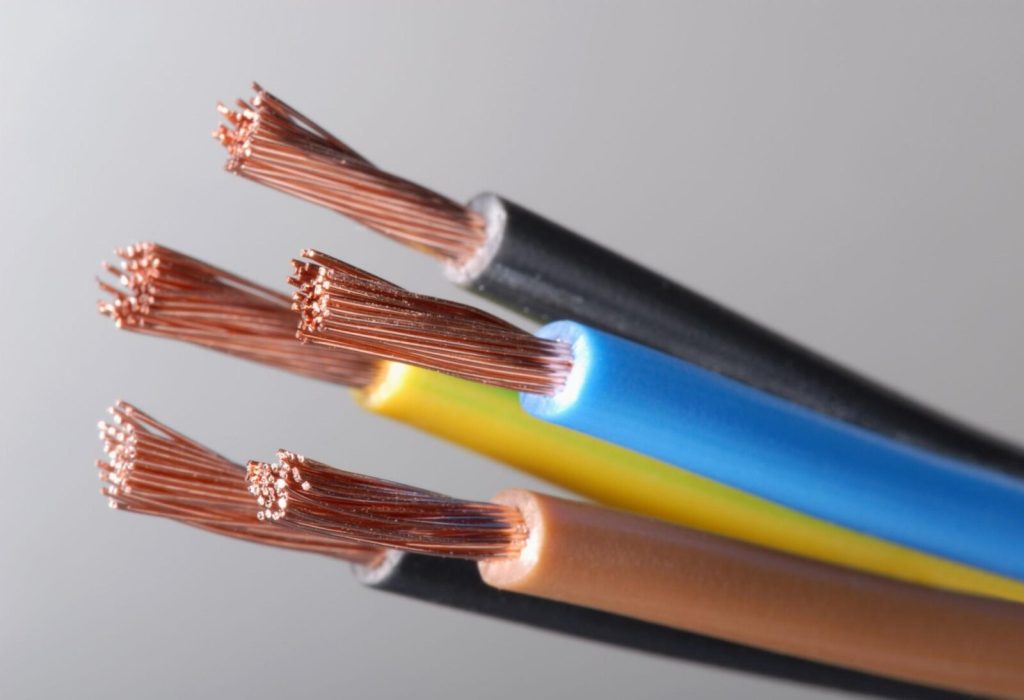

- Electrical Conductivity: Copper is renowned for its exceptional electrical conductivity, making it the material of choice for wires and components. Its ability to conduct electricity efficiently is second only to silver, but its cost-effectiveness and availability make it the standard for electrical applications.

- Antimicrobial Properties: Copper naturally inhibits the growth of bacteria and other microorganisms on its surface.

- Corrosion Resistance: Compared to other metals, copper offers considerable corrosion resistance, making it suitable for outdoor applications and environments with high humidity or salt content.

These properties make copper an excellent choice for specific applications. If you’re still unsure whether copper is right for your product, read on or use our material AI assistant to explore alternative materials.

Applications of Copper in Manufacturing

Copper is an adaptable material, shaped into various forms through processes like casting, forging, and extrusion. This versatility makes it a vital component in many mechanical parts and products.

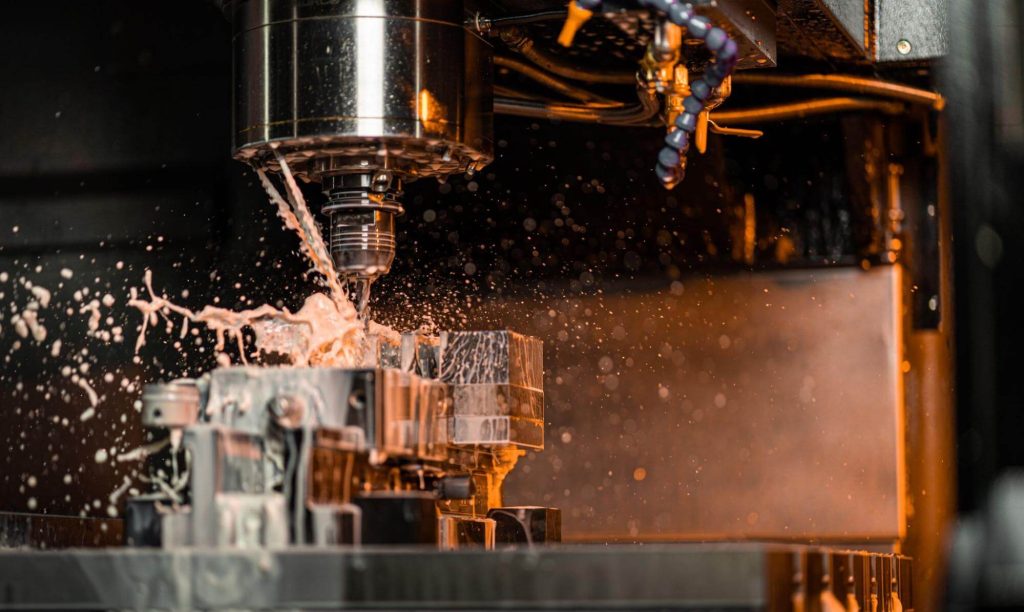

CNC Machining of Copper

In CNC machining, copper is favored for its excellent formability. However, as a relatively soft metal, pure copper can cause significant tool wear. To address this, selecting the right cutting tools and machining parameters is crucial. Copper alloys are often preferred, as they retain desirable properties while improving machinability.

Copper’s superior conductivity and ductility make it highly popular in CNC machining, especially for high-performance electrical and thermal applications. At Debaolong Seiko, we offer precision CNC machining services for copper and its alloys, achieving tolerances as tight as ±0.0001″.

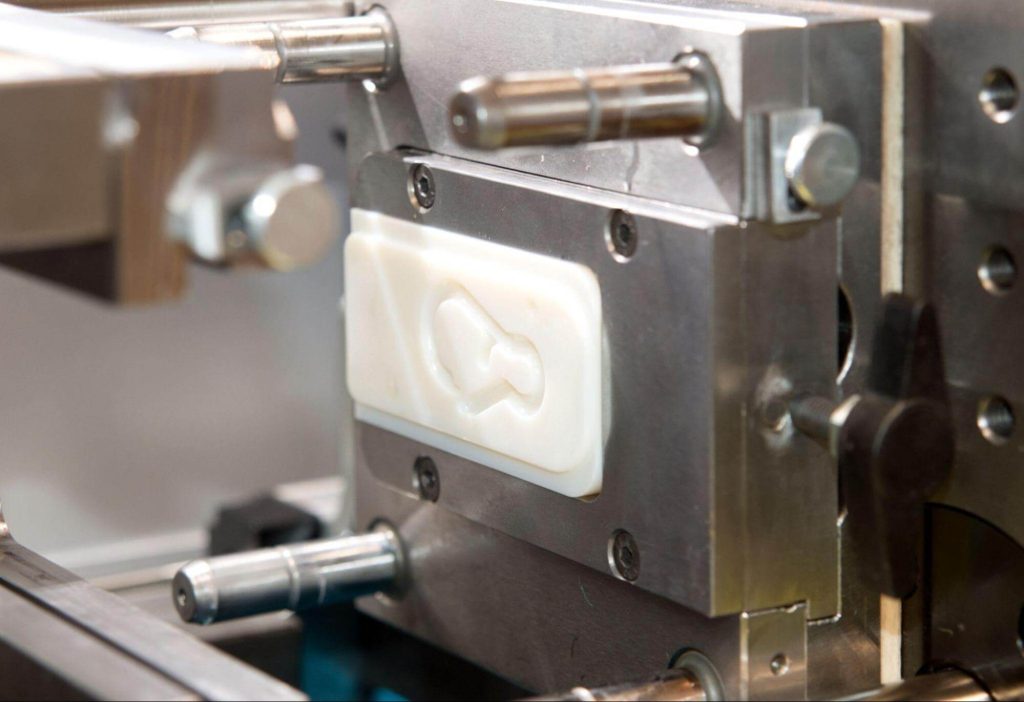

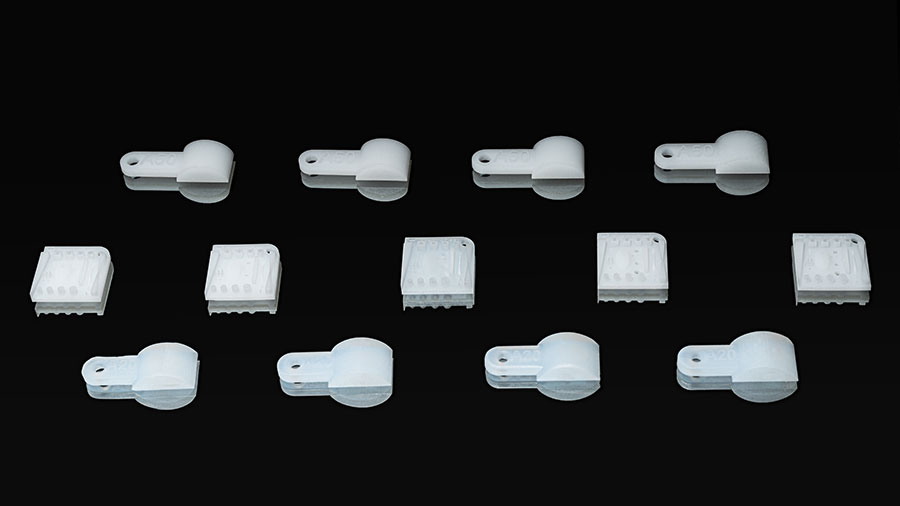

Copper in Injection Molding and EDM Electrodes

Copper is also used as an electrode in Electrical Discharge Machining (EDM), enabling precise machining even in small areas. EDM is particularly useful for creating and modifying injection molds.

Molds themselves can even be made from beryllium copper alloys, which offer excellent thermal conductivity. Additionally, Copper Injection Molding (CuMIM) technology produces highly complex heat sinks, though this differs from using copper for the mold itself.

Copper Sheet Metal

Copper sheet metal is valued for its combination of durability, flexibility, and aesthetics. It can be easily formed into complex designs, making it ideal for decorative applications as well as functional components in electronics, HVAC systems, and architectural features. Its high thermal and electrical conductivity further enhance its appeal, especially in applications requiring efficient heat dissipation or electrical connections.

With Debaolong Seiko’s advanced sheet metal manufacturing services, we deliver high-quality copper parts with tolerances up to ±0.0003″. Our services include laser cutting, bending, forming, and finishing options like anodizing and plating, ensuring your parts meet both functional and aesthetic requirements.

Copper Die Casting

Copper die casting is a specialized process that leverages the excellent fluidity and low shrinkage of copper alloys to produce complex, precision components. The technique involves forcing molten copper into a mold under high pressure, enabling the creation of intricate shapes with tight tolerances. A key advantage of copper die casting is its ability to achieve high dimensional accuracy and superior surface finishes, reducing the need for extensive post-processing.

Copper Plating

Copper plating is widely used to enhance the appearance, performance, conductivity, and corrosion resistance of components across various industries. This electrochemical process deposits a thin, uniform layer of copper onto a substrate (e.g., steel or aluminum) by immersing it in an electrolyte solution containing copper ions. Plating improves conductivity and thermal management, making it ideal for semiconductors, aerospace components, and power transmission systems.

Industrial Applications of Copper Manufacturing

Copper’s conductivity (both electrical and thermal), ductility, and malleability enable its wide range of technical applications. In fact, certain properties of copper make it indispensable to the development and advancement of technologies from electrical wiring to renewable energy systems. Here are key areas where copper is technologically utilized:

- Electrical Wiring: Copper’s primary application in wiring for homes, buildings, and power grids makes it one of the most widely used materials. Its high conductivity allows efficient electricity transmission with minimal energy loss.

- Electronics: Copper is used in manufacturing devices like computers, smartphones, and televisions. It is a key component of printed circuit boards (PCBs), the backbone of electronic devices, as it connects various electronic components.

- Power Generation and Transmission: Beyond wiring, copper is used in power-generating machinery, transformers, and generators. Its high thermal conductivity helps dissipate heat efficiently, improving operational efficiency.

- Telecommunications: Copper is used in telephone lines, coaxial cables, and even fiber optic cables. In such applications, copper cables facilitate long-distance transmission of voice, data, and video with minimal signal loss.

- Renewable Energy: Copper is critical to the research, development, and functionality of renewable energy technologies like wind turbines and solar panels. It is used in generators, transformers, and power transmission systems associated with these technologies.

- Heating and Cooling Systems: Copper’s excellent thermal conductivity makes it ideal for all types of heating and cooling systems, including radiators, heat exchangers, and refrigeration machinery. Its efficiency in heat transfer and energy distribution is unmatched.

- Medical Devices: Copper is used in various critical medical equipment, including surgical instruments, orthopedic implants, and radiation therapy devices. Its biocompatibility and antimicrobial properties expand its applications in healthcare.

- Musical Instruments: Copper alloys are valued for their acoustic properties; many high-quality brass instruments and hardware are made from copper alloys.

- Plumbing: Copper’s antimicrobial properties prevent algae and other organisms from growing in water, making it suitable for pipes and water-related fittings.

- Kitchenware: Copper is used in kitchen items from sinks to cookware, electrical fittings, and lamp bases.

Industrial Applications of Copper Manufacturing

Copper plays a crucial role in advancing industries like electric vehicles, semiconductors, and climate technology. Debaolong Seiko supports these industries with high-precision custom copper parts, enhancing conductivity, energy efficiency, and sustainability. Whether you need copper busbars for power distribution, heat sinks for semiconductor cooling, or corrosion-resistant components for renewable energy applications, our global manufacturing network ensures reliable, scalable production.

Benefits and Limitations of Copper Beyond Manufacturing

Benefits of Copper

Copper offers many other interesting properties that benefit applications beyond manufacturing. First, copper is highly recyclable. Recycled copper performs as well as new copper in any application, reducing the environmental impact of copper production by conserving natural resources. Additionally, compared to most metals like lead and mercury, copper mining and production have a relatively lower environmental footprint.

Copper is also a natural biocide, preventing algae and other organisms from growing in water. This makes it suitable for plumbing pipes and other water-related fittings. Health benefits such as improved blood circulation and reduced inflammation in the body are also associated with copper.

Limitations of Copper

Despite these advantages, there are limitations to consider. First, copper is more expensive than many other metals. This may make it a costly choice for common applications. However, its benefits—such as durability, conductivity, and corrosion resistance—often outweigh this drawback, providing value for money, especially in long-term applications.

Another potential disadvantage is its weight. Copper is a moderately heavy metal, so it may not be ideal for applications where overall weight is a concern. Generally, however, its sufficient strength and resilience make it suitable for parts requiring load-bearing capacity, as well as resistance to friction and heat.

Types and Alloys of Copper

There are various types of copper, each with unique characteristics. They can be categorized into the following families:

- Pure copper: 99.3% purity or higher

- High-copper alloys: 96%–99.3% purity

- Brass: Including zinc brass, tin brass, and leaded brass

- Bronze: Including phosphor bronze, leaded phosphor bronze, aluminum bronze, and silicon bronze

- Other alloy groups: Including copper-nickel alloys, copper-nickel-zinc alloys, leaded copper, free-machining copper, and specialty copper alloys

| Copper Alloy Family | Alloy Metals and Composition | Copper Alloys in the Family | Key Properties | Common Industrial Applications |

|---|---|---|---|---|

| Pure Copper | Copper 101: 99.9% Cu, 0.001% O Copper 102: 99.95% Cu, 0.001% O | Copper 101, Copper 102 | Corrosion resistance, high ductility and malleability, excellent electrical and thermal conductivity, low hardness and volume resistivity, moderate strength | Semiconductors, indoor/outdoor building materials, cables and fine wires, household goods, heat exchangers, metal cylinders, coins, electronic components, aerospace parts, power transmission lines |

| Brass | Cu: 55–95%, Zn: <~43%, Pb: <0.03–4.5% | 360 Brass, 70/30 Brass, Free-Cutting Brass, 272 Brass | Ductile, malleable, antimicrobial, low friction | Musical instruments, decorative items, locks, non-sparking tools, heat exchanger cores, fasteners, plumbing components |

| Gliding Metal | Cu: 90–95%, Zn: 5–10%, Fe: <0.05%, Pb: max 0.02% | C22000 (Red Brass), C23000 (Commercial Bronze), C24000, C21630 | Low work-hardening rate, moderate strength, deep drawability, durability, excellent stress corrosion cracking resistance, weldability and brazeability | Cosmetic hardware, building materials, pipes, writing instruments |

| Bronze | Cu: 80–97%, Sn: 3–20% | 932 Bearing Bronze (C93200), B20, B8, Statuary Bronze | High strength, corrosion resistance, conductivity | Tools, musical instruments, decorative items (statues), bearings, electrical contacts/relays, automotive parts |

| Cupronickel | Cu: 70–90%, Ni: 10–30% | Monel 400, C70600 (90/10), C71500 (70/30) | Silver appearance, improved strength and corrosion resistance, good ductility | Marine hardware, coins, thermocouples, strain gauges |

| Beryllium Copper | Cu: 95–99.6%, Be: 0.4–5% | C17200, C17300, C17500, C17510 | High strength, hardness, conductivity, excellent corrosion resistance | Connectors, switches, various electrical components |

| Cadmium Copper | Cu: 98–99%, Cd: 0.1–1.5% | Copper 162 (C16200) | Excellent bend life, good tensile strength, high conductivity, thermal stability | Electrical components, power transmission lines |

Table 1: Composition, Properties, and Common Uses of Copper Alloys

Conclusion

Copper’s high electrical and thermal conductivity, along with its ductility and malleability, make it an important and widely used material in mechanical parts and products. In all cases of using copper in mechanical applications, it is essential to consider the application’s requirements and select the appropriate type of copper accordingly.

With its corrosion resistance, antimicrobial properties, and sustainability, copper stands out as an exceptional material for mechanical parts and products. While copper has drawbacks—such as cost and weight—its advantages often outweigh them, providing value for money, especially in long-term applications.

For more information, contact Debaolong Seiko. You are also welcome to upload your designs to Debaolong Seiko for a quote.