The emergence of CAD systems, additive manufacturing, and CNC machining has made the design and production of complex part designs almost routine. Today, engineers are tasked with designing components that may be exposed to various factors, including extreme weather conditions, chemicals, bodily fluids, high stress or loads, impacts, and other elements that can affect product design. Such advanced designs often require advanced materials in injection molding.

In this material selection guide, we will walk you through manufacturing and design considerations for various material options, and provide material recommendations for different design goals—including glass and fiber-filled materials for stronger parts, and silicone and polyurethane for flexible components.

If the product you’re designing would benefit from prototypes or production using rigid or flexible materials, create an account and upload your part to see how our instant quoting process, expert guidance, and intelligent platform can assist you.

How to Achieve Stronger Parts: Common Types of Plastic Fillers

Glass Fiber

A common method to enhance the mechanical properties of plastic materials is adding glass fibers. These fibers improve structural properties such as strength and rigidity, and reduce part shrinkage. Glass-filled resins are relatively inexpensive and can be added to most plastics, such as nylon.

On the downside, glass fibers can make parts brittle and reduce impact strength. They also shorten mold life and cause wear on the molding machine’s barrel and nozzle. Glass-filled resins increase material viscosity, making mold filling more difficult. While glass fibers can be added to various colored resins, they may affect the appearance.

Carbon Fiber

Carbon fiber fillers can also improve the mechanical properties of plastic materials. Carbon-filled plastic parts have similar mechanical properties to glass-filled plastics but are stronger and lighter. Carbon fiber is conductive, so carbon-filled parts offer better electromagnetic shielding. Compared to glass fibers, carbon fibers more effectively enhance structural properties like strength and rigidity, and reduce part shrinkage.

The main drawback of carbon-filled parts is their high cost. Like glass fibers, carbon fibers can make parts brittle, reduce impact strength, shorten mold life, and cause wear on molding equipment. They also increase material viscosity, hindering mold filling. Note that carbon-filled materials limit part colors to black. Some resins also require very high mold temperatures, which may necessitate expensive auxiliary equipment.

Design Tips for Fiber-Filled Parts

The length of fibers aligns with the direction of material flow, creating grain orientation. Materials are stiffer when bent along the fiber length. Therefore, understanding mold design and flow simulation is helpful for gating or making design modifications as needed.

Mold Design for Fiber-Filled Parts

When glass or carbon fibers are compounded with resin, the plastic’s elastic modulus and tensile strength increase significantly, making plastic parts feel rigid. This means the plastic part will not deform easily if a heavy object is dropped on it.

However, impact strength will be lower, and the plastic will feel brittle. Flowability will decrease, and shrinkage in the direction of flow will be less than that perpendicular to the flow.

In mold design, it is difficult to set shrinkage rates based on the plastic flow direction from the gate. CAD software only allows users to set shrinkage rates in X, Y, and Z directions. This means that for large parts with tight tolerances, some dimensions may fall out of tolerance.

A solution is to leave extra tool steel in the mold (a “steel-safe” approach). After measuring the part, it is easy to remove tool steel via CNC or EDM, but adding steel to the mold is challenging. This requires welding the mold and then removing excess steel with CNC or EDM, which can cause tool deformation—detrimental to tool life and part quality.

To further modify the mold, if plastic part dimensions are out of tolerance, you need to remove or add mold steel to adjust the mold’s shape or size. To avoid this step, CNC aluminum test molds offer a fast, low-cost way to produce molds, obtain plastic part samples, and compare critical dimensions of the plastic part with the print. If any critical dimensions are out of tolerance, the production mold can be adjusted accordingly (produced after the test mold). The purpose of the test mold is to identify which dimensions will be out of tolerance and which key features work as designed. Once the impact of differential shrinkage in different flow directions on dimensions is understood, 3D models can be adjusted when making hard tools.

Filled materials wear down molds faster than unfilled plastics, so when using these materials, the mold cavity and inserts must be made of hardened steel. The heat deflection temperature (HDT) is also higher, allowing the material to be used in higher-temperature environments. This increases the difficulty of ultrasonic welding.

In some cases, fibers may float to the surface of visible plastic parts, so most filled plastic parts are used for internal components. To avoid this, the mold cavity can be textured.

How to Achieve Flexible Parts: Polyurethane (PU) vs. Silicone

Polyurethane (PU) and silicone materials offer different approaches to creating soft parts. PU uses compression molding and RTV tooling, while silicone and TPU use injection molding. A major drawback of silicone is flash; when flash is cut or trimmed, residue often remains. Additionally, when injecting silicone, the mold must be heated—a reversal of the traditional process of heating the material. Injecting TPU is easier to process while offering properties similar to silicone.

Polyurethane (PU)

Polyurethane (PU) is divided into two categories: thermoset PU and thermoplastic PU (TPU). The key difference is that thermoset materials crosslink during processing and cannot be reused. Thermoplastic polyurethane, on the other hand, can be recycled and reused. You can learn more about thermoset vs. thermoplastic materials here.

Thermoset polyurethane is primarily used for prototyping via a process called polyurethane casting or room-temperature vulcanization (RTV). Polyurethane casting uses a master part coated with liquid silicone elastomer, which cures at room temperature. Once the silicone hardens, the master is removed, resulting in a flexible, elastic mold that can produce copies of the master.

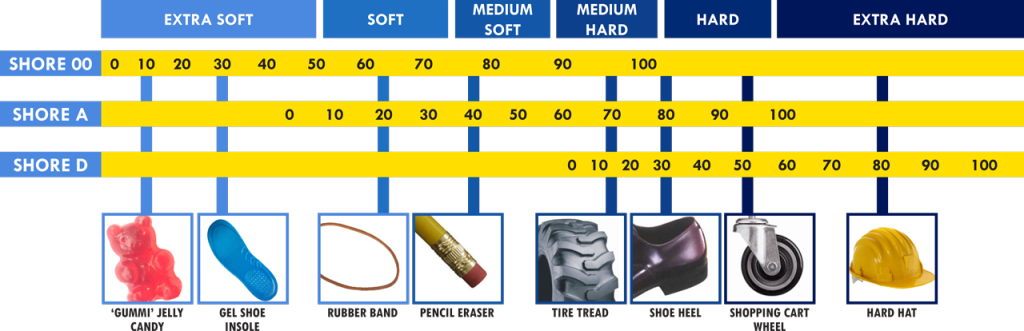

Parts made via this process range in hardness from 30A to 85D. Flash is unavoidable in polyurethane casting. For hard plastic parts, flash can usually be trimmed manually, and scars can be sanded to make them less noticeable. However, for soft parts like PU, flash is harder to remove cleanly. PU offers better abrasion resistance than thermoplastic elastomers (TPE) and polyvinyl chloride (PVC), making it suitable for casters and shoe soles.

Thermoplastic PU parts can be made by injection molding, so the parting line can be very precise and accurate (no flash). The hardness range of thermoplastic PU is from 65A to 85D, so the resin can be as soft as rubber or as hard as rigid plastic. Thermoplastic polyurethane is commonly used in overmolding, such as manufacturing the jacks of electronic wires. Wires made of thermoplastic PU material have better elasticity and bending test results than those made of PVC or TPE.

Silicone

Silicone is a thermoset resin, offering excellent heat and weather resistance. Silicone parts are manufactured using three methods: RTV casting, compression molding, or liquid silicone injection. Silicone cannot be reprocessed or recycled.

Silicone has many uses and benefits. It is an excellent choice for gaskets and O-rings. Due to its heat resistance, non-toxicity, and ease of cleaning, it is commonly used in kitchenware, personal care products, and medical devices.

However, silicone has drawbacks. Flash is common, and trimming often leaves residue. Additionally, injection molding of silicone requires heating the mold rather than the material—a reversal of traditional processes. Injection-molded TPU is easier to process while offering properties similar to silicone.

Manufacturing Flexible Parts

As mentioned, RTV is the most common method for prototyping soft materials, with typical hardness ranging from 40A to 50A. However, polyurethane casting molds can only produce a limited number of samples.

Compression molding is typically used for mass-producing standard silicone parts. Flash is unavoidable and must be trimmed manually, leaving visible scars. Most compression-molded parts have flash thicker than 0.2 mm, with few factories able to achieve 0.1 mm thickness.

Compression molding cycle times are usually a few minutes. Molds are typically made of steel with multiple cavities to improve production efficiency. When designing silicone parts, there is no need to follow the rule that the rib-to-nominal wall thickness ratio must be ≤ 0.6. In most cases, even with undercuts, side actions are not required in the tool; parts can be manually removed from the mold.

Liquid silicone injection is very similar to injection molding but with a key difference: the mold is heated to high temperatures. Lead times are typically longer than for injection molding, but parts can be as detailed as injection-molded parts, with little to no flash.

The image below shows typical samples of different hardness levels:

Design Tips for Flexible Materials

Start with thinner wall thicknesses and a range of durometers to find the desired flexibility for molded parts. Wall thickness can be adjusted in 0.1 mm increments using a steel-safe approach (adding material). Parts can be molded across a range of durometers simultaneously, or start with one and adjust after testing samples. Ribs are an effective way to add rigidity via quick EDM modifications to the tool.

Other Material Considerations for Injection Molding

Flowability (Viscosity)

Flowability is a critical factor when selecting materials, especially for very thin-walled or large parts.

Flowability varies between resin types and grades. For example, ABS has general-purpose, high-flow, and high-impact grades.

Different ABS types offer varying mechanical properties and prices. Some are ideal for high-gloss surfaces; others are suited for electroplating; some have good flowability for thin-walled or large parts.

Typically, for different grades of the same resin, higher flowability correlates with lower mechanical properties. Melt flow index (MI) indicates resin flowability and can be found on Prospector, a trusted global search engine for materials and compositions. Resins with good flowability are used for thin-walled plastic parts (e.g., phone battery casings) or large parts (e.g., baby bathtubs).

- Resins with good flowability: LCP, PA, PE, PS, and PP.

- Resins with moderate flowability: ABS, AS, PMMA, and POM.

- Resins with poor flowability: PC, PSF, and PPO.

Mechanical Design

Engineering performance requirements determine the choice of material. Glass-filled resins are ideal for strong parts requiring wear resistance and strength, such as computer housings, toys, and other consumer goods. In contrast, unfilled materials like ABS or polycarbonate (PC) are better for decorative parts that do not require special strength. Polypropylene (PP) or polyethylene (PE) are suitable for containers or parts with living hinges.

Dimensional Stability

When designing plastic parts, consider the precision required for fitting with other components. For tight fits, select plastics with good dimensional stability, such as PC, ABS, or POM. PA and PP are less ideal for such applications due to their higher shrinkage rates, which can affect fit. However, if PA or PP must be used, nucleating agents can be added to improve dimensional stability.

Impact Strength

Impact strength reflects a material’s toughness—low impact strength means brittleness. Impact strength data can be found in material datasheets and on Prospector.

Typically, recycled plastics have lower impact strength than virgin resins. When glass or carbon fibers are compounded with resin, impact strength decreases, while load and wear resistance increase.

During the design of new plastic parts, it is important to consider the type, magnitude, and frequency of forces the part will endure. For example, handheld electronics may be dropped, so the housing material should be PC or PC/ABS—PC offers nearly the highest impact strength among common engineering plastics.

Weather Resistance and UV Resistance

For outdoor applications, plastic parts must have good weather and UV resistance. Acrylonitrile styrene acrylate (ASA) is a resin with excellent weather and UV resistance, with mechanical properties similar to ABS.

If other resin types must be used, UV stabilizers and weathering agents can be added. However, any plastic resin should undergo thorough testing before use to ensure it meets product requirements.

Temperature Considerations

Temperature resistance is another key factor when selecting resins. For example, engine compartments reach 70–90°C during operation, so all materials used there must withstand this temperature. Prospector includes UL yellow card information for various resins, including long-term use temperatures.

For more information, contact Debaolong Seiko. You are also welcome to upload your designs to Debaolong Seiko for a quote.