Aerospace CNC machining involves producing high-precision parts with complex geometries and tight tolerances, such as engine components, structural supports, and landing gear. CNC machining of aerospace parts enables the fabrication of lightweight, durable materials and supports rapid prototyping, low-volume, and high-volume production. It meets stringent safety standards while reducing lead times and minimizing human error.

This article provides an overview of aerospace CNC machining, describing the types of parts manufactured, processes used, materials, challenges, quality control measures, cost considerations, and trends. It also outlines the role of CNC machining in aerospace prototyping and production.

Why Precision Matters in Aerospace

In aerospace precision machining, achieving tight tolerances is critical because many aircraft components belong to life-sustaining systems, such as jet engines and landing gear. Proper CNC machining tolerances ensure aerospace parts have correct dimensions for optimal performance, including aerodynamics. Additionally, precisely fitting parts minimize friction, reduce wear, and improve fuel efficiency—a key concern for both commercial and military aviation.

Importantly, aerospace CNC machining produces precision parts repeatedly and consistently. These interchangeable components are vital for global fleets requiring fast, efficient maintenance to avoid costly Aircraft on Ground (AOG) situations. Non-compliance with part quality and safety standards can also lead to part recalls or hefty fines from regulatory bodies like the U.S. Federal Aviation Administration (FAA) and the European Union Aviation Safety Agency (EASA).

Types of Aerospace Components Produced via CNC Machining

CNC aerospace machining is used to manufacture the following aircraft parts:

- Structural components

- Tail assemblies

- Engine and powertrain parts

- Interior components

- Doors and hatches

CNC machining is also commonly used for satellites, spacecraft, and rockets.

Structural Components

CNC-machined structural components are used throughout the airframe. Examples include ribs, spars, flaps, and ailerons. Ribs and spars provide mechanical strength, helping wings maintain rigidity under extreme forces. Flaps and ailerons are movable surfaces that guide airflow. Landing gear struts and beams are also machined to precise specifications, as they must withstand extreme stress.

Tail Assemblies

Aircraft CNC machining creates internal structures for vertical and horizontal stabilizers, as well as aerodynamic surfaces that provide longitudinal (pitch) and/or directional stability and control. Elevators and rudders—movable control surfaces in the aircraft tail—are also precision-machined for smooth operation.

Engine and Powertrain Components

Aerospace CNC machining produces turbine blades and casings, engine mounts, and pylons. Turbine blades feature complex geometries. Engine mounts must securely fasten engines to the airframe to withstand flight pressures. Engine pylons connect aircraft engines to wings or fuselages and are precision-machined to handle loads and engine vibrations. Thermal management components, such as heat exchangers, are also often CNC-machined, alongside casting and brazing processes.

Interior Components

Aircraft cockpits and cabins contain numerous CNC-machined parts, including seat rails, support brackets, clamps, and braces. These smaller components often secure larger assemblies and may be critical to the aircraft’s structural integrity and safety performance.

Doors and Hatches

Landing gear doors and access panels require precision machining for proper fit and smooth surfaces to support effective sealing. When aircraft doors are closed during flight, they must withstand tens of thousands of pounds of pressure—leaks are unacceptable for safety.

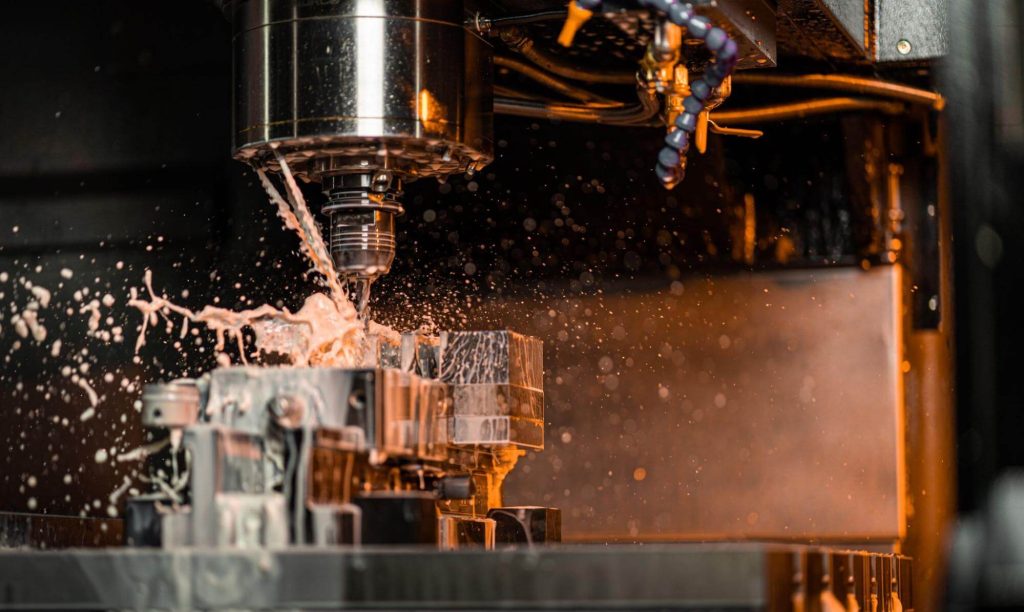

CNC Machining Processes Used in Aerospace Manufacturing

CNC machining for aerospace manufacturing falls into the following categories:

- 3-axis CNC machining (milling)

- 5-axis CNC machining (milling)

- Precision CNC turning (lathe)

- CNC grinding and finishing

- Additive manufacturing integration

CNC machining is suitable for both prototyping and high-volume production.

3-Axis CNC Machining

3-axis CNC machining is typically used for parts with simpler geometries and lower complexity. The equipment may have lower upfront costs, reducing capital expenditure and allowing smaller businesses to utilize CNC milling. This aerospace CNC machining process is suitable for larger parts, such as fuel pumps, motor housings, and landing gear. Think of a 3-axis CNC mill as a workhorse capable of removing large amounts of material.

5-Axis CNC Machining

Aerospace parts with complex geometries—difficult or impossible to produce via 3-axis machining—are better suited for 5-axis CNC machining. Parts with multiple faces or contoured features benefit most from this process. With the ability to move along more axes simultaneously, 5-axis CNC machines can approach parts like turbine blades and impellers from nearly any angle. Advantages of 5-axis CNC machining include reduced setup time, better surface finishes, more efficient material removal, and support for complex holes and undercuts.

Precision CNC Turning

CNC turning is a key part of aerospace machining, used for circular and cylindrical aerospace parts requiring high precision. CNC turning is performed on a lathe, where the workpiece rotates, and material is removed as it contacts a fixed tool. Applications include shafts and threaded components in mechanical systems, as well as aerospace fasteners, pins, and bushings. Automated CNC lathes enable manufacturers to easily produce large quantities of identical parts.

CNC Grinding and Finishing

Aerospace components subject to friction—such as shafts and bearings—require high-quality surface finishes for smooth operation. CNC grinding refines the finish of these machined parts without compromising critical tolerances. Highly automated CNC grinders also ensure greater consistency between parts.

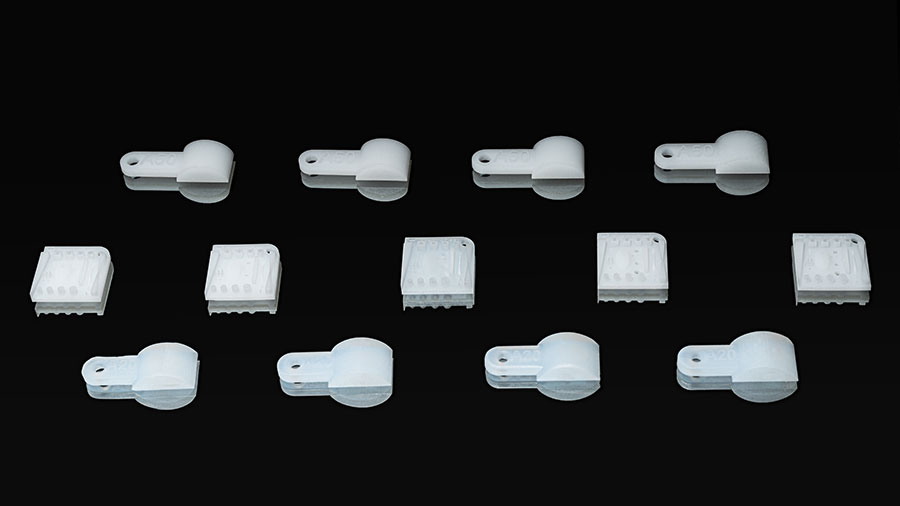

Additive Manufacturing Integration

Aerospace CNC manufacturing can integrate with additive manufacturing (AM) for post-processing operations. Hybrid machines can switch between adding material via 3D printing and removing material via CNC machining. This form of hybrid manufacturing combines the design freedom of additive manufacturing with the precision of high-quality CNC machining.

Materials Used in Aerospace CNC Machining

Materials used in aerospace CNC machining are both strong and lightweight. Examples include:

- Aluminum alloys

- Titanium and superalloys

- High-performance polymers

- Composites

With additive manufacturing integration, 3D-printed plastics and metals can also be used.

Aluminum Alloys

Aluminum alloys are strong, lightweight, corrosion-resistant, and cost-effective. They also have good thermal conductivity for efficient heat dissipation and fatigue resistance. Several aluminum alloys are tailored for aerospace applications:

- Aluminum 2024: High strength, excellent machinability, low density, and good fatigue resistance—used in thermal management and structural components.

- Aluminum 6061: Moderate strength and corrosion resistance—used in structural parts, hydraulic systems, engine components, fittings, and couplings.

- Aluminum 7075: Strong and durable—used in aircraft wings, fuselage bulkheads, and structural elements.

Titanium and Superalloys

Titanium alloys are valued for their high strength-to-weight ratio, excellent corrosion resistance, and ability to withstand higher temperatures than steel or aluminum alloys. They also have fatigue resistance and a thermal expansion coefficient similar to composites commonly used in aerospace, further enhancing heat and mechanical wear resistance. Titanium is used in airframes, engine parts (e.g., casings, fasteners), landing gear, and structural elements.

Superalloys are metals with superior creep resistance, oxidation resistance, and corrosion resistance compared to traditional alloys. Designed for extreme environments (high temperatures, pressures, and corrosion), they exhibit excellent mechanical strength, resistance to thermal creep, surface stability, and oxidation/corrosion resistance. Base elements in superalloys are typically nickel, cobalt, or iron, combined with chromium, molybdenum, titanium, aluminum, and other elements. Superalloys are critical in jet engines (turbine blades), power plants, and chemical/petrochemical industries where ordinary metals fail under extreme conditions. Both titanium alloys (e.g., Ti-6Al-4V) and superalloys (e.g., Inconel) are difficult to machine.

High-Performance Polymers

Metals are not the only materials used in aerospace CNC machining. PEEK, a high-performance polymer, is used in critical engine components due to its ability to maintain tight tolerances and withstand high temperatures. ULTEM, another high-performance polymer, has one of the highest dielectric strengths among thermoplastics and is often used to insulate cables in aircraft cabins. Various plastics are also widely used in aircraft interiors.

Composites

Composites for lightweight, high-strength parts are well-suited for CNC machining. Carbon fiber, glass fiber, and aramid fiber are examples in the aviation industry. Today, approximately 50% of the Boeing 787 Dreamliner is made of composites. The Airbus A350 XWB also uses strong, lightweight composites for wings and fuselages to improve fuel efficiency.

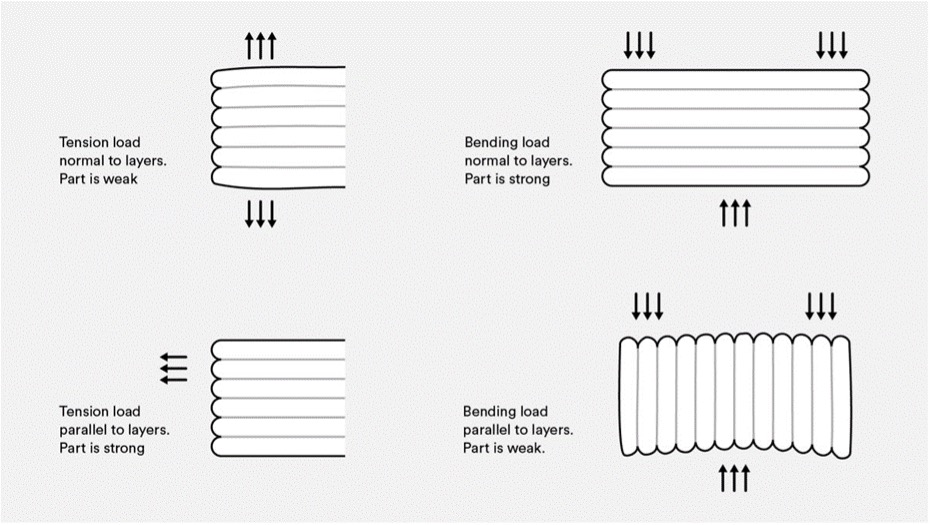

Key Challenges in Aerospace CNC Machining

Aerospace CNC machining supports diverse part types, manufacturing processes, and materials. However, achieving the tight tolerances and complex geometries required for many components is challenging. Design engineers must optimize part tolerances for each application, and machinists must select the most efficient manufacturing methods. Tolerance stack-up analysis is essential, and GD&T 标注 should be used where possible.

When working with multiple components, designers must prioritize parallelism and perpendicularity tolerances; otherwise, CNC-machined parts may misalign. Material selection is critical, as different aerospace materials have varying mechanical, thermal, and electrical properties. Work hardening, stress, and thermal effects can complicate machining. For corrosion resistance, numerous surface treatments and coatings are available—common options in aerospace include anodizing, conversion coatings, plating, painting, and passivation.

Quality Control in Aerospace CNC Machining

For optimal results, CNC-machined aerospace parts must be designed with final inspection processes in mind. The harder a part or feature is to machine, the more challenging it is to measure tolerances. Coordinate measuring machines (CMMs), laser scanning, and other inspection methods, including non-destructive testing (NDT) techniques, are typically used.

CNC machining quality control also requires process repeatability. The global aerospace industry demands consistency and reliability across production runs, and projects may require an AS9100-certified manufacturing partner. Unlike ISO 9001 (used across industries), AS9100 is specific to aerospace and more comprehensive, incorporating all ISO 9001 quality management system requirements plus additional clauses related to aerospace part manufacturing quality.

Cost Considerations in Aerospace CNC Machining

Material selection, part complexity, and production volume are three primary drivers of aerospace CNC machining costs. By balancing cost efficiency with precision and quality needs, designers can avoid cost overruns. However, part cost is not the only consideration: lightweight composites may be more expensive than metals but reduce aircraft fuel costs.

Designers must also compare the pros and cons of outsourcing aerospace machining versus in-house production. Titanium alloys and superalloys are among the hardest metals to machine, so specialized CNC machining services for these materials may be necessary. Similarly, if in-house facilities only have 3-axis CNC equipment, 5-axis CNC machining services may be required.

The Role of CNC Machining in Aerospace Prototyping and Production

One advantage of CNC machining is its support for rapid iteration of aerospace prototypes. Depending on part complexity, turnaround times can range from hours to days—critical in design phases with frequent iterations. Once CNC machines are programmed, they can support low-to-high-volume production.

During aerospace prototyping, designers test part form, fit, and function. Aerospace CNC machining produces parts with extreme precision, ensuring prototypes closely resemble final products. This precision is vital for aerospace designers, as is the ability to machine multiple materials. For example, if an aerospace part is made from aluminum 6061, designers can use the same material in both prototyping and production—unlike 3D printing, where materials may have different properties than those used in subtractive processes like CNC machining.

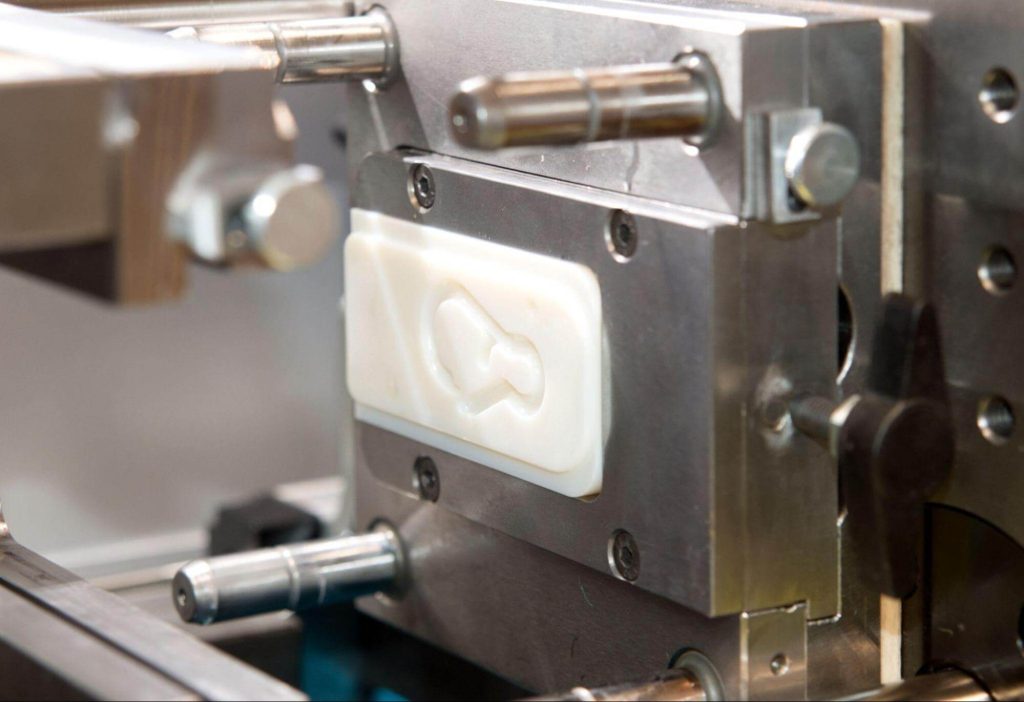

In production, aerospace CNC machining ensures consistent quality across every part. 5-axis machining enables complex geometries and tight tolerances that other manufacturing methods may not achieve. Custom tooling used in aerospace machining includes specialized fixtures, locating pins, and bushings.

Future Trends in Aerospace CNC Machining

Artificial intelligence (AI), machine learning (ML), and advanced automation are shaping the future of aerospace manufacturing and driving industry innovation. Hybrid manufacturing—integrating traditional CNC machining with digital and additive manufacturing technologies (Industry 4.0)—is also helping aerospace manufacturers achieve higher production efficiency.

Meanwhile, the aerospace sector is becoming greener: designers are developing aircraft that consume less fuel or use more sustainable energy sources (e.g., algae-based biofuels). Electric vertical takeoff and landing (EVTOL) aircraft are transforming aviation, replacing liquid fuel with battery power—yet EVTOLs still require CNC-machined aircraft parts.

For more information, contact Debaolong Seiko. You are also welcome to upload your designs to Debaolong Seiko for a quote.