CNC robotics is revolutionizing manufacturing by integrating automated CNC equipment with industrial robots. It combines the precision and consistency of computer numerical control (CNC) with the versatility and flexibility of articulated, arm-like robots. Together, these technologies enhance efficiency, reduce human error, and enable complex tasks.

What Are CNC Robots?

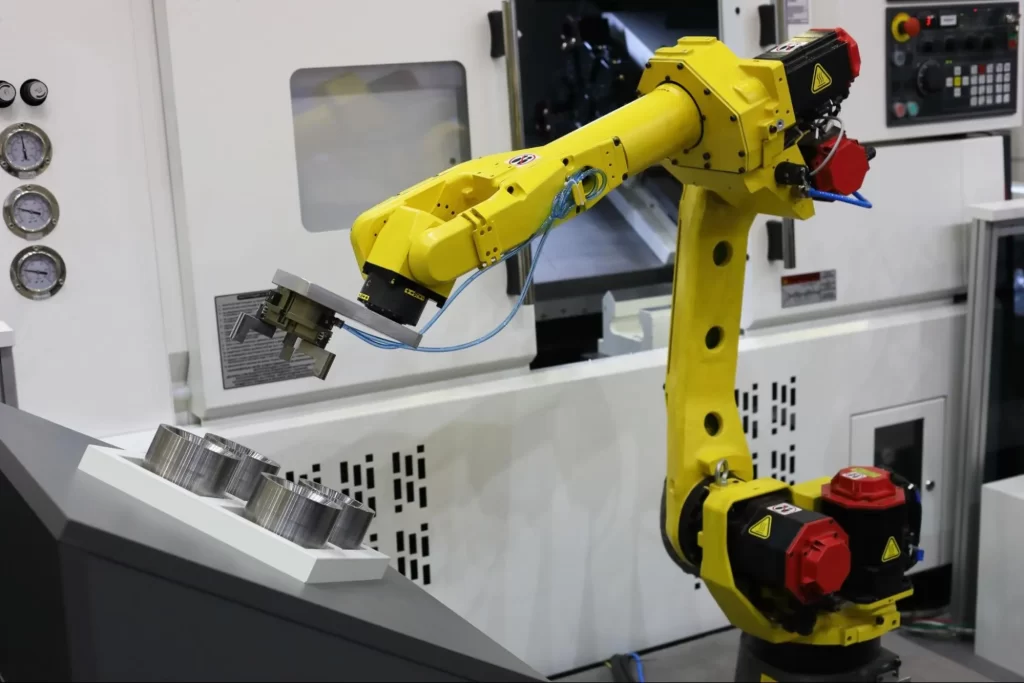

CNC robotics merges CNC machining principles with advanced robotics. Its benefits include improved efficiency, higher precision, reduced labor costs, and enhanced safety. Applications range from loading/unloading materials into CNC equipment to workpiece handling, positioning, and performing repetitive tasks.

It’s important to note that not all CNC machines use robots, and many robots operate independently of CNC equipment. For example, a machine operator might manually load metal into a CNC grinder, while industrial robots could package parts in a separate area.

What Is CNC Automation?

CNC automation uses computerized systems to control machine tools and processes like milling, drilling, grinding, and turning. By shaping materials with minimal human intervention, CNC machining produces complex parts with superior precision and consistency. It is widely used in automotive, aerospace, and medical device manufacturing.

CNC machines offer greater flexibility, simpler programming, and higher precision than numerical control (NC) equipment, which relies on manual input. While CNC equipment has higher upfront costs and requires basic computer programming knowledge, operators can easily switch between programs and run the machines continuously.

In production, computer control systems manage CNC machine speed and movement. These systems fall into categories like motion control, loop control, and axis count, each interpreting programmed instructions to guide tools such as drills, hones, and gear shapers.

How Is CNC Machining Automated?

For designers, CNC automation starts with a computer-aided design (CAD) file of the part. Manufacturers upload this CAD model to computer-aided manufacturing (CAM) software (e.g., MasterCAM, AutoDesk Fusion) to generate CNC machine instructions with toolpaths.

In automated CNC machining, adaptive control adjusts parameters in real time. Feedback from on-board sensors monitors the process, ensuring quality by modifying speed, feed rate, and cutting depth to account for tool wear or material inconsistencies.

Beyond sensors and vision systems, automated CNC equipment uses programmable logic controllers (PLCs) to manage machine functions and workflows. Conveyors move parts between production stages, while robotic arms assist with material handling and repetitive tasks—often programmed for non-machining tasks like part transport.

What Is Robotics?

Robotics is a technical field focused on designing, building, and using robots. Like CNC equipment, robots are programmable machines that perform tasks autonomously or semi-autonomously. They typically include sensors, actuators, and end effectors:

- Sensors: Detect environmental conditions (e.g., presence of a workpiece).

- Actuators: Convert sensor signals into physical motion (powered by electricity, pneumatics, or hydraulics).

- End Effectors: Tools at the end of robotic arms (e.g., grippers, end mills, drills).

Robotic systems use complex software for motion planning, path optimization, and real-time monitoring, plus a controller that dictates tool usage, part placement/removal, and tasks like packaging for shipping.

How Do CNC Machines Differ from Robots?

CNC machines and robots are related but distinct, differing in purpose, motion, flexibility, and structure:

- Purpose: CNC machines specialize in machining tasks (cutting, drilling, milling). Robots are versatile, programmable for machining or non-machining tasks (maintenance, assembly, material handling).

- Motion & Control: CNC machines follow fixed, preprogrammed paths on 3–5 axes. Robots use preprogrammed code but have articulated joints (degrees of freedom) enabling flexible movement—reaching around obstacles, welding at angles, or performing complex assemblies.

- Flexibility: CNC equipment is task-specific; robots are adaptable, reprogrammable for multiple operations. Combining automated CNC equipment with robotics allows manufacturers to handle everything from material loading to inspection and packaging.

- Structure: CNC machines have rigid frames to withstand high-speed machining forces, minimizing vibration that could affect precision. Many industrial robots have durable plastic enclosures—strong but more flexible than metal.

What Tasks Do CNC Robots Perform?

CNC robots handle diverse tasks, from machining and milling to mass production, wiring, and welding:

- Robotic Machining/Milling: Offers flexibility for large or irregular workpieces (e.g., automotive/aerospace components). Articulated joints enable navigation of complex geometries and hard-to-reach areas, with precision cutting beyond traditional CNC capabilities.

- Mass Production: Ideal for high-volume runs, as CNC robots operate continuously with consistent precision, reducing errors in tasks like part inspection.

- Robotic CNC Routers: Cut and shape materials (metal, wood, plastic) for applications like furniture manufacturing, with quick switching between materials and processes.

- CNC Robotic Welders: Add flexibility to automated welding, following programmed paths to ensure consistency—critical for automotive safety and aerospace component integrity.

Key Trends in CNC Robotics

Technological advancements and evolving industry needs are shaping the future of CNC robotics:

- AI & Machine Learning (ML): Integrated to enhance decision-making, predictive maintenance, and process optimization. AI handles tasks requiring human-like intelligence, while ML uses algorithms to improve performance through data analysis.

- Collaborative Robots (Cobots): Designed to work alongside humans in shared spaces (e.g., loading/unloading CNC machines). They reduce fatigue, injury risks, and defects from human error.

- Soft Robotics: Focuses on flexible, compliant robots (e.g., elastomer-based actuators embedded in fabric or fibers) for gentle handling of delicate or irregularly shaped objects.

- Swarm Robotics: Coordinates multiple robots to collaborate on tasks, boosting efficiency in large-scale operations (e.g., manufacturing large structures requiring multiple processes).

Future Outlook and Market Impact

The industrial robotics market was valued at $17B in 2023 and is projected to reach $32.5B by 2028, with collaborative robots expected to grow fastest. Cobots offer flexibility, easy programming, and fast ROI, helping address labor challenges—such as an aging skilled workforce and a shortage of young replacements (per Deloitte and The Manufacturing Institute).

CNC Robotics Case Studies

Real-world examples highlight CNC robotics’ benefits:

- Cobots Accelerate CNC Machining: Go Fast Campers (Belgrade, Montana) uses Universal Robots (UR) cobots to load 航空级 metal blanks into Haas CNC machines. The cobots flip parts for secondary machining, with a single program controlling 174 part types and one operator managing four machining cells.

- Industrial Robots Triple Output: A specialty optics manufacturer combined KUKA robots with Mazak Integrex machines, tripling production. Operators shifted from loading/unloading to process control, improving efficiency.

Challenges and Limitations

While CNC robots save time and money, they face challenges:

- High Initial Costs: Investments in CNC machines, robots, software, and infrastructure.

- Complexity & Integration: Programming difficulties and compatibility issues between CNC machines and robots from different manufacturers.

- Accuracy Limits: Robotic arms may have lower precision than CNC machines due to joint play, thermal expansion, and wear.

- Reliability & Downtime: Over-reliance on automation increases vulnerability to technical issues, with limited manual intervention options.

- Environmental Sensitivity: Dust, temperature, and humidity can disrupt sensors and moving parts.

For more information, contact Debaolong Seiko. You are also welcome to upload your designs to Debaolong Seiko for a quote.