In the field of injection molding services, manufacturers and designers can utilize a variety of technologies to produce high-quality, functional, and aesthetically pleasing plastic parts. Among the most advanced and versatile technologies are two-color injection molding and overmolding. Both techniques offer unique advantages and are suitable for different applications, but they are often confused or misunderstood. By understanding the complexities of each method, professionals can optimize their manufacturing processes and leverage the strengths of each technology to meet their specific project requirements.

Understanding Two-Color Injection Molding

Definition of Two-Color Injection Molding

Two-color injection molding, also known as dual injection, multi-color, or 2K molding, is a highly specialized process that combines two different materials or colors into a single injection-molded part. This advanced molding technology involves injecting two types of polymers into the same mold through separate injections but within the same molding cycle. The result is a complex part that can feature different colors, textures, or material properties, seamlessly integrated without the need for post-molding assembly.

Process and How It Works

The two-color injection molding process is performed in a dedicated molding machine equipped with two or more injection units. The core of this process lies in the precise control of the injection units and the mold design, which needs to accommodate multiple injections. It typically unfolds as follows:

- First shot: The first material is injected into the mold, forming the base layer of the part.

- Mold rotation or plate shifting: After the first injection, the mold rotates or shifts to align the first part to a new cavity position for the second injection.

- Second shot: The second material is injected, bonding chemically or mechanically to the first layer to form the final component.

The entire process is highly automated and controlled, requiring less labor and minimizing the risk of human error, which is crucial for mass production of complex parts.

Ashwin Kasirajan is a manufacturing engineer who works with customers to develop injection molding projects. To understand the importance of tool design in two-color injection molding, he explains: “The tooling must allow both stages of the part to be molded in the same mold for maximum production efficiency. The design must account for two separate injection stages that can rotate 180 degrees or be oriented to allow robotic transfer of components. Each injection station is run by an independent injection unit that can control the injection speed and pressure for each material used.”

Kasirajan also notes the importance of precision throughout the process: “Because the mold moves or rotates along an axis, it is essential to ensure interchangeability of the core and cavity on both sides.”

Throughout production, coordinate measuring machines (CMMs, a type of three-dimensional measuring equipment) are used to check the precision of the mold to prevent injection defects that may arise from misalignment, such as flash.

Key Applications and Industries

Two-color injection molding is particularly valuable in industries where part durability, aesthetic quality, and production efficiency are critical. Common applications include:

- Automotive parts: Such as seals, gaskets, airbag covers, and other components requiring a combination of rigid and flexible materials.

- Medical devices: Suitable for ergonomic and safe medical tools, which often need a combination of soft grips and more robust structures.

- Consumer electronics: Aesthetics and functionality go hand in hand in manufacturing items like phone cases, wearables, and remote controls.

Two-color injection molding is the preferred choice for many high-end applications in these fields because it can mold parts that meet strict technical specifications while also satisfying the demands of visually appealing designs.

What is Overmolding?

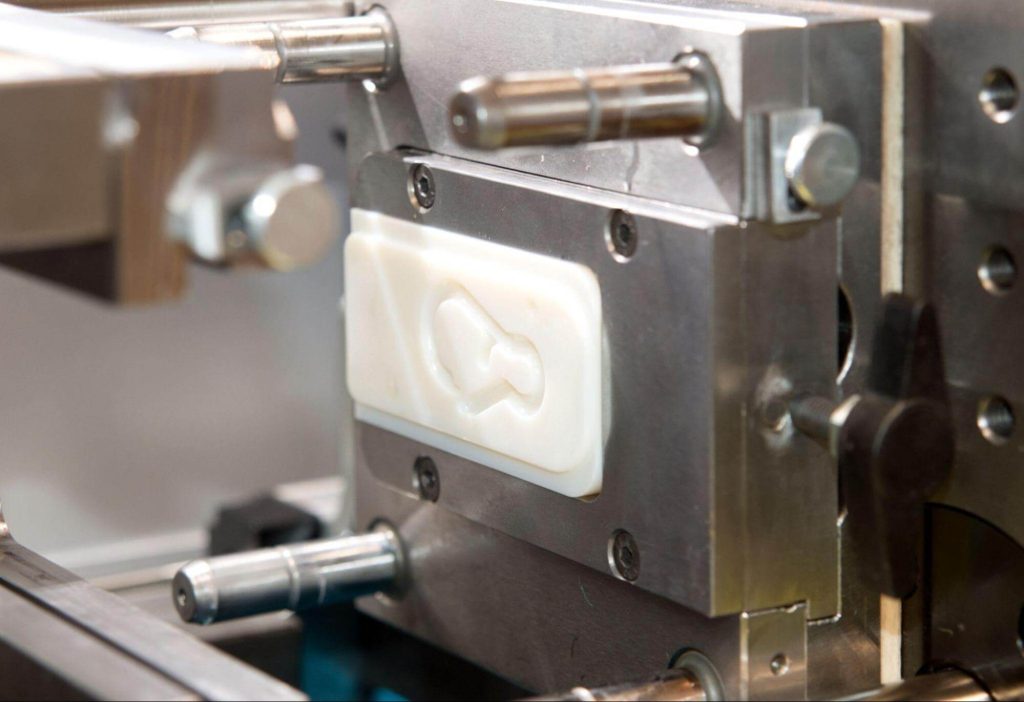

Overmolding is a versatile manufacturing technique that creates a single part by sequentially injecting two or more materials onto a base part or substrate. The primary material (usually a rigid plastic) forms the substrate, while the secondary material (typically a softer plastic or rubber) is molded over the first material. This process not only enhances the functionality of the product but also improves its aesthetics and tactile experience.

Detailed Overview of the Overmolding Process

The overmolding process involves several key steps:

- Substrate manufacturing: Initially, the substrate part is molded using a standard injection molding machine. This part acts as a skeleton for molding the secondary material.

- Substrate placement: After the substrate is molded, it is placed into a new mold where the overmolding material will be injected. This can be done manually or automatically, depending on the complexity and volume of production.

- Second material injection: The second material is injected onto the substrate, forming a bond during the molding process. The bond can be mechanical (interlocking shapes) or chemical (compatible materials).

- Curing and ejection: Once the second material is molded, it cools and solidifies, fusing with the substrate. The final part is then ejected from the mold.

Overmolding Applications Across Industries

Overmolding is widely used across various industries for its ability to add enhanced properties to parts, such as improved grip, aesthetics, and durability. Typical applications include:

- Consumer goods: Toothbrushes, cookware, hand tools, and other handheld devices benefit from overmolding’s soft-grip materials over hard substrates.

- Medical equipment: Overmolding is used to create ergonomic, non-slip surfaces on medical devices such as surgical instruments and equipment handles.

- Sports equipment: Many sporting goods, such as golf club grips, bicycle handle grips, and protective gear, utilize overmolding to combine performance with comfort and durability.

Overmolding’s versatility makes it ideal for customizing parts that require tactile and aesthetic qualities in addition to functional performance. This method is particularly useful when production scale or budget constraints do not justify the higher initial costs associated with two-color injection molding.

When comparing overmolding with two-color injection molding, understanding their specific applications and the nuances of each process is crucial for determining the best approach to meet any given manufacturing requirement.

Comparing Two-Color Injection Molding and Overmolding

Both two-color injection molding and overmolding are used to manufacture multi-material components, enhancing functionality, aesthetics, and product performance. However, they differ significantly in their approaches, applications, and ideal production scenarios.

Similarities:

- Multi-material production: Both technologies allow the integration of different materials into a single component.

- Enhanced product features: They can improve a product’s mechanical properties, aesthetics, and ergonomics.

- Reduced assembly requirements: Each process reduces the need for post-molding assembly, streamlining the manufacturing workflow.

Differences:

- Process complexity and equipment: Two-color injection molding requires complex machinery that can inject two plastics into the same mold in the same cycle. Meanwhile, overmolding can often be accomplished with standard injection molding machines and a secondary process.

- Material bonding: In two-color molding, the bond between materials needs to be strong and is usually chemically based, requiring compatible materials. Overmolding can utilize mechanical bonding techniques, allowing a wider range of material combinations.

- Cost and volume efficiency: Two-color molding is generally more cost-effective for high-volume production due to its efficiency and speed, while overmolding is more suitable for small batches or prototypes due to its simpler setup and lower initial costs.

Material Considerations

Selecting the right injection molding materials is crucial for the success of both processes. For two-color injection molding, materials must be carefully chosen to ensure they bond well and can withstand molding temperatures and pressures without degradation. Typically, materials with similar melting temperatures and chemical properties are selected.

In contrast, overmolding offers greater flexibility in material selection because the secondary material only needs to adhere mechanically to the substrate or be chemically bonded using adhesives or primers. This allows the use of materials with different properties, such as a rigid plastic base with a soft silicone or rubber overlay.

Ideal Production Volumes

- Two-color injection molding: Best suited for high-volume production, where initial setup and mold design costs can be amortized over large quantities. It is particularly advantageous when thousands or even millions of parts are needed with consistent quality and precision.

- Overmolding: More suitable for small to medium-sized projects that require production flexibility. Overmolding is cost-effective for short-run production as it can utilize standard injection molding equipment and simpler tooling modifications.

Two-Color Injection Molding vs. Overmolding: Choosing the Right Method for Your Project

The decision between two-color injection molding and overmolding depends on several factors, including project scale, budget, material requirements, and end-product applications.

Two-color injection molding is usually the best choice for large-scale production that requires high precision and highly compatible material integration.

Conversely, overmolding provides the necessary flexibility and cost efficiency for small batches or when working with a wider range of materials.

Kasirajan simply states, “If the quantity is not too high (only a few thousand or ten thousand), choose overmolding to save some mold costs. If your program requires 500,000 or more units, the more cost-effective process is two-color injection molding.”

“But,” he advises, “depending on the part’s structure, certain features can only be achieved with two-color injection molding, while others can only be done with overmolding.”

Frequently Asked Questions: Two-Color Injection Molding vs. Overmolding

- What are the most commonly used materials in these two processes?

In both two-color injection molding and overmolding, thermoplastics are widely used for their versatility and ease of molding. For two-color injection molding, materials such as ABS (acrylonitrile butadiene styrene), polycarbonate, TPE (thermoplastic elastomer), and TPU (thermoplastic polyurethane) are popular. These materials are chosen for their ability to bond well during molding and withstand the rigors of repeated use.

Overmolding often uses similar substrates, such as ABS and polycarbonate, but typically pairs them with softer, more flexible materials like silicone or soft PVC. These combinations provide enhanced grip, aesthetic quality, or additional functionality such as shock absorption or water resistance.

- How do I determine which process is best for my product?

Choosing the right process depends on several factors:

- Material compatibility: Ensure the materials you select are suitable for bonding in your chosen process.

- Production volume: Consider two-color injection molding for larger volumes due to its efficiency and lower per-part cost at scale. Overmolding may be more suitable for small to medium-scale production.

- Complexity and functionality: Evaluate the complexity of your design and the required functionality. Two-color injection molding is better for complex designs requiring precise material integration, while overmolding is ideal for adding soft-touch surfaces or non-slip grips.

- Which process is more cost-effective: two-color injection molding or overmolding?

Two-color injection molding is generally more cost-effective for high-volume production due to its ability to produce complex multi-material parts in a single cycle, reducing labor and operational costs. However, the initial investment in setup and tooling is substantial. Overmolding, while potentially more costly per part due to longer cycle times and increased labor, requires less upfront investment and is more cost-effective for smaller production runs. - How does the final product quality differ between two-color injection molding and overmolding?

Two-color injection molding typically results in more consistent and stronger bonds between materials because the process is fully automated and materials are selected based on their chemical compatibility. This can lead to improved structural integrity and performance. Overmolding, while providing good quality and functional enhancement, may face challenges with material adhesion if not properly designed, which could affect durability. - How do cycle times compare between the two-color injection molding and overmolding processes?

Two-color injection molding generally has shorter cycle times as it completes the part in one continuous, automated cycle. Overmolding requires multiple cycles (one for each material layer), which can increase total production time, especially when transferring substrates between molds involves manual labor. - Which process offers greater design flexibility: two-color injection molding or overmolding?

Overmolding provides greater design flexibility as it can combine a variety of materials that do not necessarily have to be closely compatible. It allows for adding different textures, colors, and properties while reducing restrictions on the molding environment. Two-color injection molding is precise and efficient for producing complex multi-material parts. However, material positioning and bonding require material compatibility and design precision.

For more information, please contact us at Debaolong Seiko. You are also welcome to upload your design to Debaolong Seiko for a quote.