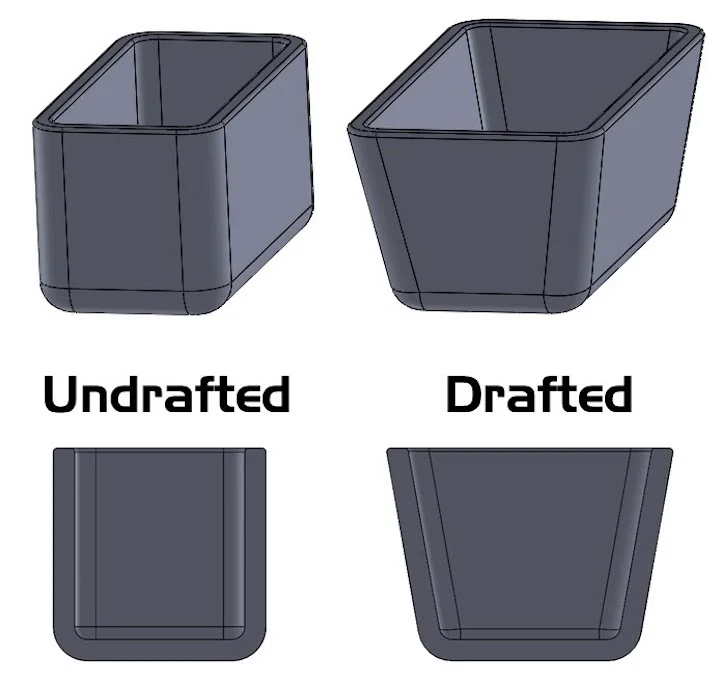

Draft angle in injection molding refers to the application of an angle or taper on the vertical surfaces of injection-molded parts. Measured in degrees, draft facilitates smoother part ejection, reduces tool wear, and shortens cooling times. The benefits of correct drafting include fewer defects, faster cycles, and lower costs.

Typically, designers apply a draft angle of 2° to 2° on injection-molded parts with a mold depth of up to 1.5 inches. Applying such a slight taper may seem simple, but you can’t add the same amount of draft to every part—and the minimum and maximum draft angles in injection molding can vary significantly.

There are many reasons for this. For starters, draft varies by injection molding material or resin. With hundreds of different resins available, including commodity plastics and specialty materials, it’s easy to understand why there’s no standard draft angle for injection molding.

Part features, surface finish, injection molding standards, draft direction, and mold design also determine how much draft to apply. Some draft is always better than none, but remember that draft angles in injection molding are not optional—at least if you want to produce scratch-free and cost-effective parts.

What happens if an injection-molded part doesn’t have enough draft? Sometimes, the mold’s ejector pins can damage the part’s finish or geometry. Insufficient draft also causes mold wear due to friction and the resulting abrasion, which occurs when the injection-molded part doesn’t have enough space to clear the mold.

This article explains how to avoid these issues so you can get complex parts at amazing speeds using draft angle injection molding. Read on to learn more and download this free e-book for other design guides, such as wall thickness, transitions, and corners.

Draft and Injection Materials

When thermoplastic resin cools inside an injection mold, the polymer shrinks by a certain percentage. This reduction in size creates surface tension between the walls of the plastic part and the walls of the injection mold. In turn, this tension prevents the part from sliding smoothly during ejection.

Since different thermoplastics cool and shrink at different rates, designers need to consider the thermal behavior of the resin they intend to use. Generally, plastics with a higher shrinkage percentage require a larger draft angle. Beyond shrinkage rate, there are other properties to consider.

Hard, brittle, and abrasive materials such as glass-filled plastics require a larger draft angle compared to soft, ductile, or self-lubricating resins like nylon or polyethylene (PE). For nylon, draft may not be strictly necessary, but it is still recommended.

The table below contains draft angles for some commonly used injection molding materials.

| Material | Minimum Draft | Recommended Draft |

|---|---|---|

| Nylon | 0° | 1° |

| Polyethylene (PE) | 0.5° | 1.5° |

| Polyvinyl Chloride (PVC) | 0.5° | 1.5° |

| Polypropylene (PP) | 1° | 2° |

| Polycarbonate (PC) | 1.5° | 2° |

Draft and Part Features

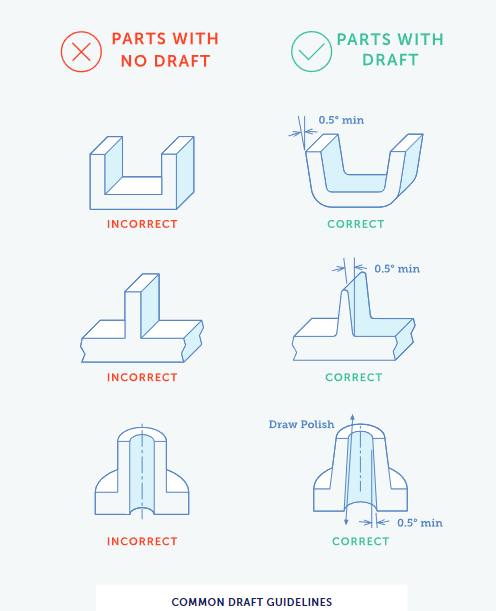

The walls of your injection molded part aren’t the only features that require a draft angle or taper. All vertical part features, including ribs and bosses, require an adequate draft. The depth of these features and their minimum thickness determine the specific angle to apply. The table below explains.

| Feature Depth | Minimum Thickness / Draft |

|---|---|

| 0.25 inches | 0.040 inches / 0.5° |

| 0.5 inches | 0.040 inches / 1°; 0.060 inches / 0.5° |

| 0.75 inches | 0.040 inches / 2°; 0.060 inches / 1°; 0.080 inches / 0.5° |

| 1 inch | 0.060 inches / 2°; 0.080 inches / 1°; 0.100 inches / 0.5° |

| 1.5 inches | 0.080 inches / 2°; 0.100 inches / 1° |

| 2 inches | 0.100 inches / 2° |

Draft and Surface Finish

Plastic injection molding can impart specific polishing or textures to parts during the molding process. After the mold is made, the desired surface treatment is applied to the tool. Then, during injection molding, this surface treatment is transferred to the part surface.

Parts with smoother surfaces require less draft because they eject more easily and are less likely to drag along the mold surface. In contrast, heavily textured finishes require more draft. Typically, part designers add 1.5° of draft for every 0.001 inch or 0.025 mm of texture depth.

Here are some general injection molding draft angle guidelines based on surface finish and texture.

- Smooth surfaces: 1 to 2 degrees (typical)

- Light texture: 3 degrees

- Heavy texture: 5 degrees or more

For textured surfaces on plastic parts, heavier draft is crucial to avoid drag marks. Parts with leather or snake-skin-like surface treatments may require even greater draft (10° or more) because the texture is created through a series of small undercuts, which complicates part ejection.

Draft and Injection Molding Standards

Standards for surface finish are defined by industry associations and companies. The Society of the Plastics Industry (SPI) and Verein Deutscher Ingenieure (VDI) are two such industry associations. Mold-Tech (MT) and Yick Sang (YS) are companies with their own standards.

Within each surface finish standard, there are hundreds of different options. For identification purposes, each finish has a designation consisting of the organization’s acronym followed by letters or numbers. For example, MT-11010 is the Mold-Tech designation for a light mold texture.

The surface finish table below lists the required draft for the most common SPI, VDI, MT, and YS surface treatments. For achieving mirror finishes, electrical discharge machining (EDM) is used instead of CNC machining or hand polishing.

| SPI Standard | Draft | Mold-Tech Texture | Draft |

|---|---|---|---|

| A-1 | 2° | MT-11000 | 1° |

| A-2 | 2° | MT-11010 | 1.5° |

| A-3 | 2° | MT-11020 | 2.5° |

| B-1 | 1° | MT-11030 | 3° |

| B-2 | 1° | VDI Texture | |

| B-3 | 1° | VDI-18 | 1° |

| C-1 | 1° | VDI-24 | 1.5° |

| C-2 | 0.5° | VDI-33 | 3.0° |

| C-3 | 0.5° | YS Texture | |

| D-1 | 1° | YS20001 | 1° |

| D-2 | 2° | YS20005 | 3° |

| D-3 | 3° | Mirror EDM | 3° |

Draft Direction and Injection Mold Design

When applying draft to an injection-molded part, ensure that the draft is aligned with the mold’s draw (the direction in which the core and cavity separate). Otherwise, your plastic part may fail to stay in or stick to the half of the mold that contains the ejection system.

It’s also important to consider part features such as holes. For example, for a rectangular part with four through-holes, drafting the holes toward the cavity may cause the part to stick to the cavity rather than the core. A better approach is to draft the holes toward the core where the ejector system is located.

The position of the parting line also affects draft. If the mold’s parting line is stepped, a special surface called a shut-off is needed to ensure there’s no gap between the two halves of the mold when closed. Typically, part designers apply a draft angle of 5 to 7 degrees to avoid this issue.

If the parting line is in the middle of the part, such as with a solid cylinder, incorporate draft on both ends of the part. This is because your part requires not one but two 脱模动作,both of which need adequate draft.

The construction material of the mold also influences draft decisions. For example, aluminum molds are not as precise as steel molds. They also use different tools called milling machines for processing. As a result, aluminum molds may require larger draft angles to prevent dimensional deviations.

For achieving some finishes, steel molds are necessary. For example, Debaolong Seiko recommends using hardened steel molds to achieve SPI grades A-1, A-2, or A-3. Hardened steel is more resistant to potential ripples, sagging, and peaks during machining than aluminum or soft steel molds and polishes better.

Debaolong Seiko’s Draft Angle in Injection Molding

As you’ve learned from this article, determining the draft angle for an injection-molded part is not that straightforward. There are many factors to consider, including thermoplastic resin, part features, surface finish, injection molding standards, draft direction, and mold design. You also need a skilled partner.

Typically, designers apply a draft angle of 2° to 2° on injection-molded parts with a mold depth of up to 1.5 inches. It’s best to determine the amount of draft you need early in the design process. This way, you won’t have to redesign parts to make them easier and cheaper to mold.

For more information, contact us at Debaolong Seiko. You are also welcome to upload your design to Debaolong Seiko for a quote.